Ok, one thing led to another(S):

1-I made a double indicator tram setup, using 1-2-3 blocks and/or just to bed/table. I found the Y1-axis side a slight problem as decribed by others, where as I undestand the geometry of the Y1-axis around the centre of the spindle is not similar to the X1/X2 axis(Y2=OK), due to head/Slide adjustments. Interesting changes happens to the Y1 & Y2 points if I adjust those two nuts extra on head which other similar mills probably dont have. I will have to chew deep on this one.

2-Using it I dicovered the spindle moved up & down and sideways too much for any liking. I could have a good tram say 2 out of 10 times turning the spindle, its not reliable.

3-I made a tool/setup to replace the bearings, the inner sides as well as outer sides in quil, minor mods same tool for both. I did this after local Case TRactor shop broke race of the larger Timken bearing, bought another one.

4-Removed Quil/spindle. Removed chinese bearings and replaced today with Timken made in Poland roller tapered bearings. I noticed to preload the bearings is not that difficult in this case…You press last small bearing in with spindle in quil till it feels like tentioned..If its too much, you just tap the end back with an aliminium hammer(Or other safe hammer)…You then righten the in this case one locknut & washer locked. The locknut can be used to apply load after the bearing initial seating by pressing it in..I played around between the locknut/washer & tapping to get the preload I am happy with.

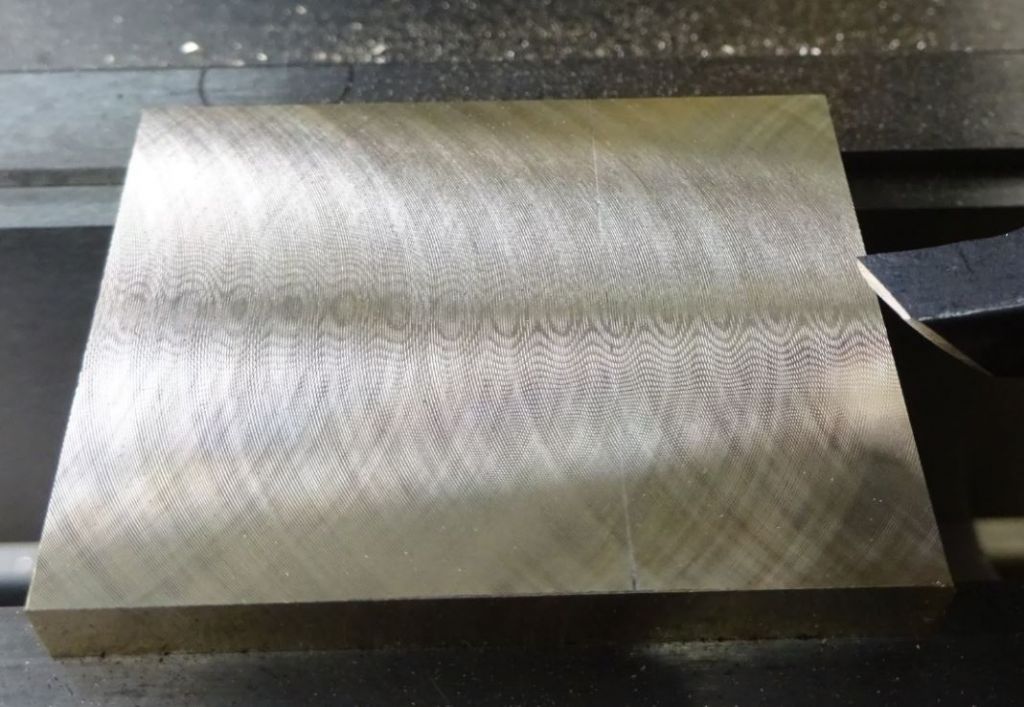

5-The relief of this was a pleasure, zero play up/down or sideways, I was happy with preload and no play. I expect to see a different cut pattern now.

6-This brings me to the looseness of original chinese bearings.. Could it be due to tapping out the MT4 tools.. In beginning it was hard tapping, but after a tip from this forum I made a handwheel, similar size to an old Singer knitting machine with socket to tighten drawbar with hand, since the the knock loose was not an issue as to feel…….Now that I assebled the spindle/quil myself, it would be easy to detect if knocking out the MT4 tools is a problem.

I took photos and will post it later. I am busy reassembling everything again, and will tram it again to see the difference in feel of doing it.

Chris Mate.