Hey everyone.

Well my new toy (WM290V) is here, it only took Warco (Warren machine tools) a week from the date of order to delivery.

Arrived on one pallet (well two but the crate one on top another normalone), very well packed and even had an anti tilt indicator on it!!

It was dropped off at the top of the driveway by the delivery company (very helpful chap) and now I had the task of moving it through a gate, up the side of the house and into the garage.

I unpacked it and removed as much weight as I could including the tailstock, chuck, compound etc and lifted one end of the crate base up onto axle stands (used my sack truck to lever it up) then did the same the other end so I could remove the big pallet and place my wheels under it, lowered it down onto the wheels and rolled it up into the garage.

Next I assembled the stand, I couldn't find instructions but wasn't too taxing.

The lathe was then rolled to its new home and a chain hoist put on a double joist above, lifting straps attached to each end and now the moment I had been worried about, lifting 250kg up on my own, turns out I had absolutely nothing to worry about, up she went easy peasy.

Once it was high enough I put the stand underneath and lowered the lathe back down, aligning the bolt holes as I did so. The bolts hold the lathe to the stand were tightened up, then I leveled it all out (digital spirit level on the ways)

Levelling feet need another nut on top to lock them once adjusted but they only come with one her foot (well bolts as they are not actually feet) 4 at the headstock end 2 at the tailstock end (will add 2 more at the tailstock asap)

The lathe was pre cleaned and oiled and the DRO was pre fitted I just had the fit the display and the bits I had taken off.

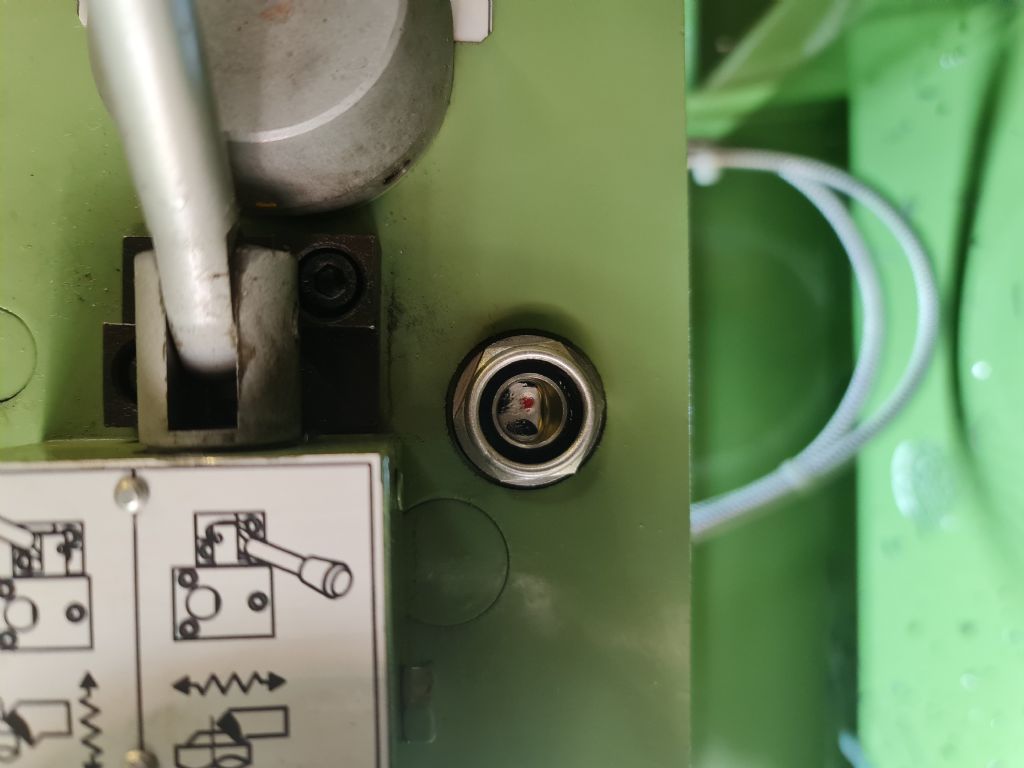

Powered her up a did the test runs, all good apart from the Apron oil level is low and the compound is very tight.

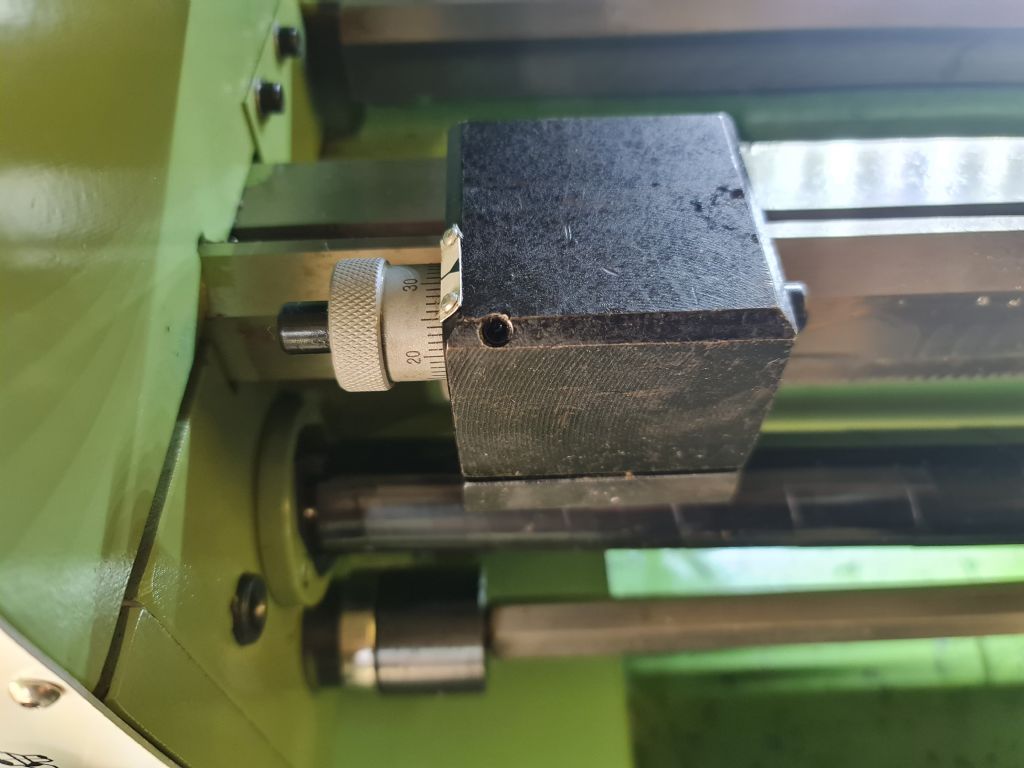

Overall I'm impressed, crossslide and compound are tapered gibs, (compound gib is as loose as it will go, just one turn on the screw and it falls out), they had even pre fitted my QCTP when they tested it.

Couple of minor paint defects here and there and the top of the front plate is creased where the join to the change gear cover is but very I'm generally pleased.

Few things that could be improved:

8 feet bolts and locking nuts for the top and bottom of them instead of only the bottom would be good.

Stand assembly instruction would be nice.

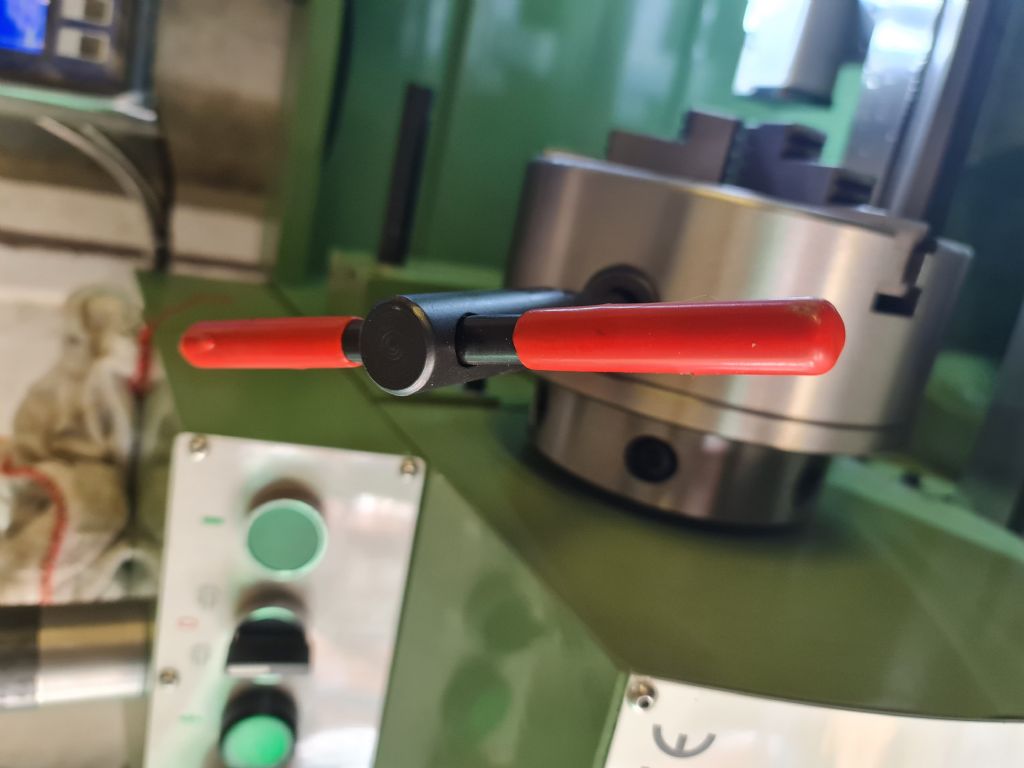

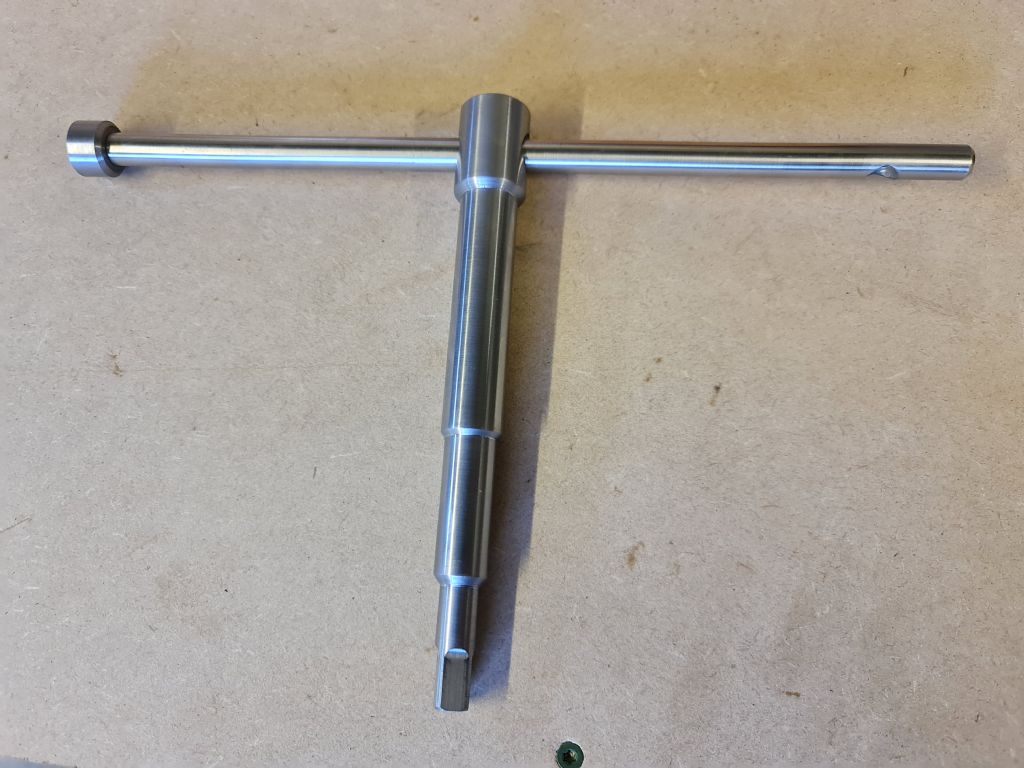

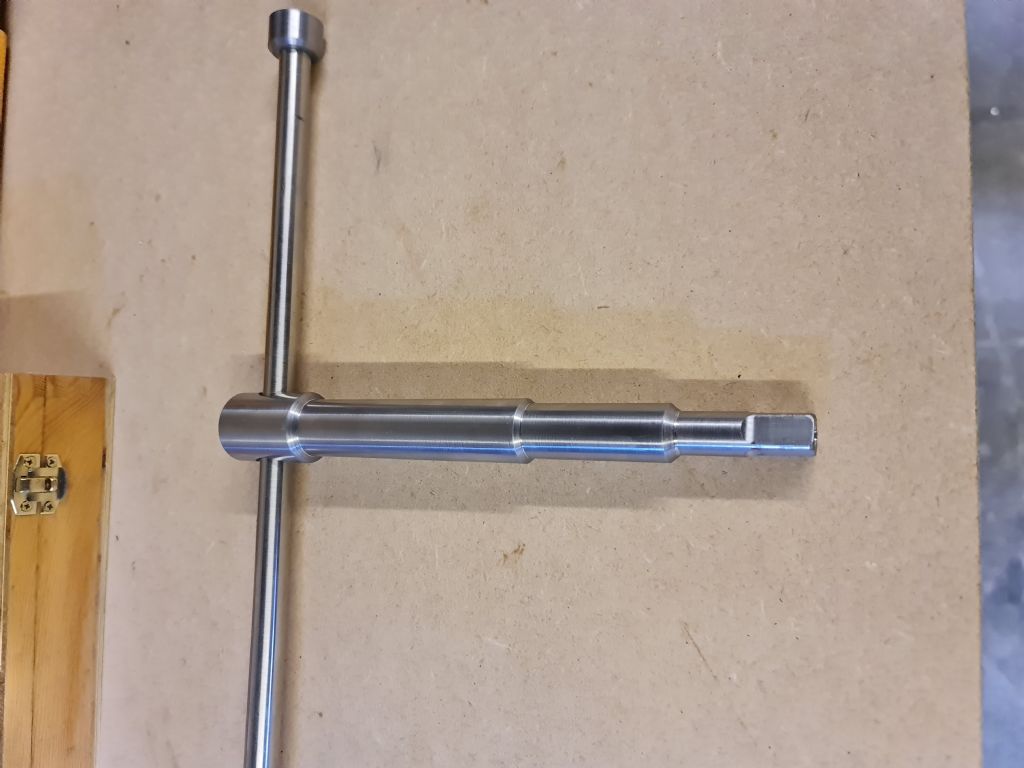

Longer chuck key so the 'T' is clear of the control panel (first thing I'm going to make on it) to save the knuckles.

The usual paintwork defects.

Good points:

Tapered gibs rather than the usual grubscrew adjustment is brilliant.

Camlock chuck mount is excellent.

Has a very bright LED work light already fitted.

Came with a live centre that I wasn't expecting!

Has a mains isolation switch as well as the E stop.

Will add pictures to the next post if I can work out how to do it  Excuse the mess in the garage, my shed is arriving tomorrow so can move all the stuff out and get the benches made and the milling machine up off the ground, the garage is going to be machine shop and shed is going to be wood working but it's all piled in the garage at the moment from the move.

Excuse the mess in the garage, my shed is arriving tomorrow so can move all the stuff out and get the benches made and the milling machine up off the ground, the garage is going to be machine shop and shed is going to be wood working but it's all piled in the garage at the moment from the move.

Rob Wheatley.