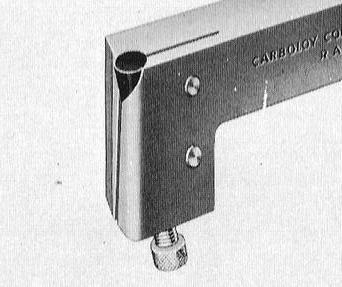

Most of the time, I use a tangential type tool, in the Lathe. So that is obviously my main preference.

Kenelm Lee Guiness (The inventor of and proprietor of KLG sparking plugs, back in the '20s) apparently used to drive through cross roads at 60 mph. He claimed that you were in the danger area for a shorter time!

All sorts of different conclusions can be drawn from the same set of figures. Just depends which axe you are seeking grind.

"Tea, (or whatever other beverage you prefer) must be poisonous; because everyone who drinks it eventually dies".

On the other hand, without a regular, adequate, fluid intake you will die.

Which thought process is illogical?

A sense of proportion, and Common Sense, are not that common.

Winston Churchill was quoted as saying that "There are liars, damned liars, and statisticians"

Howard

Hopper.