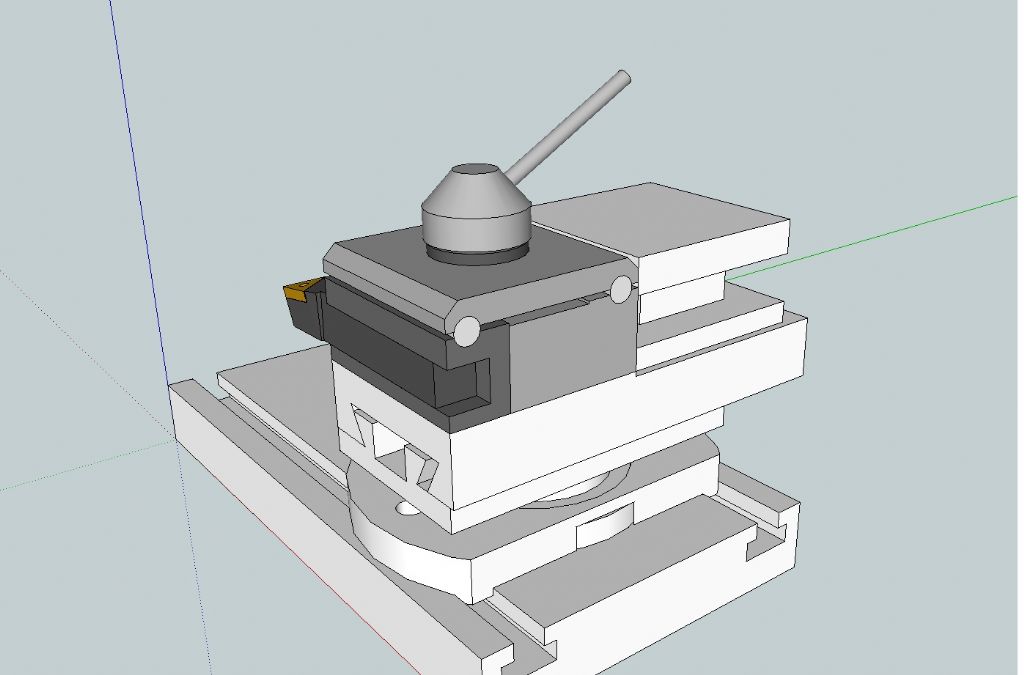

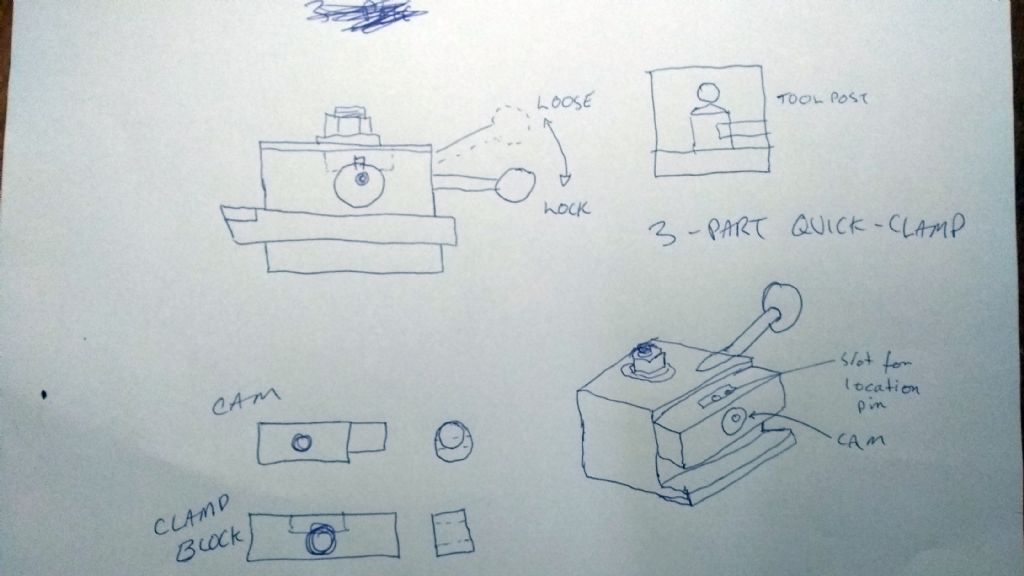

Posted by ChrisB on 28/08/2019 18:20:51:

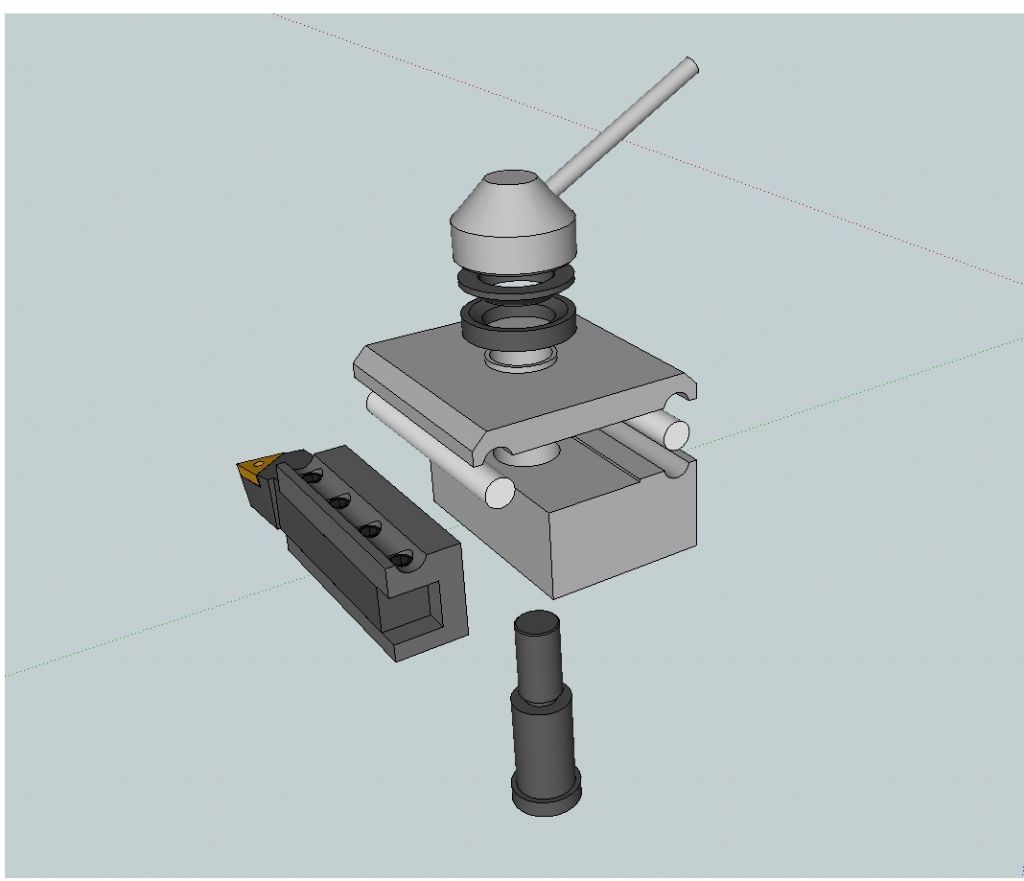

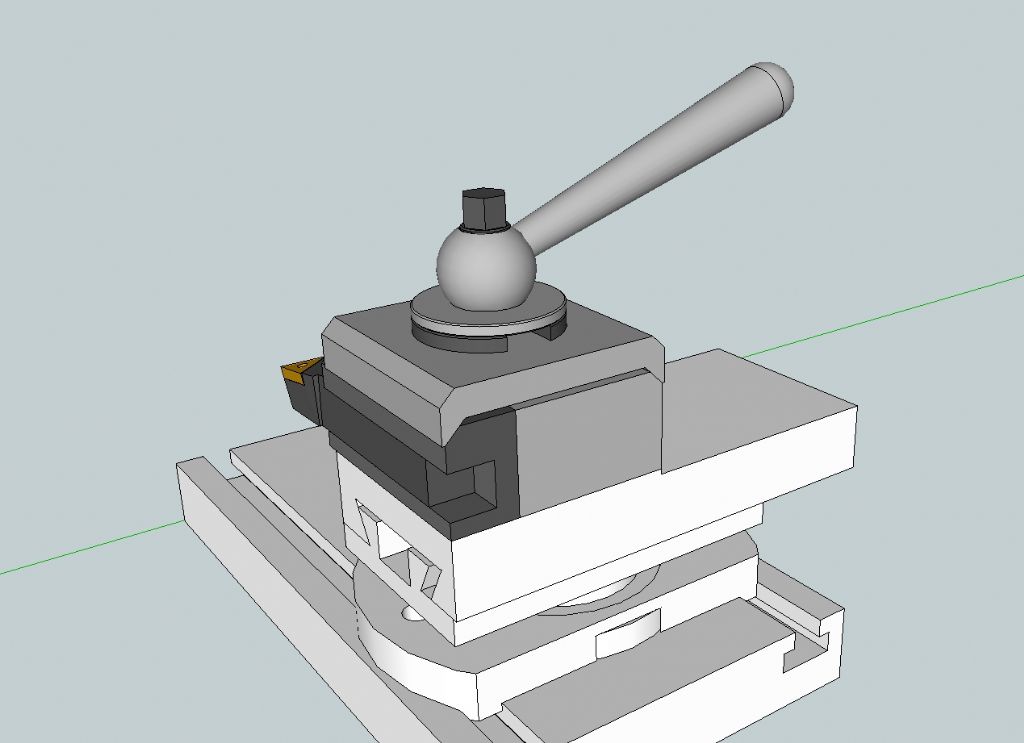

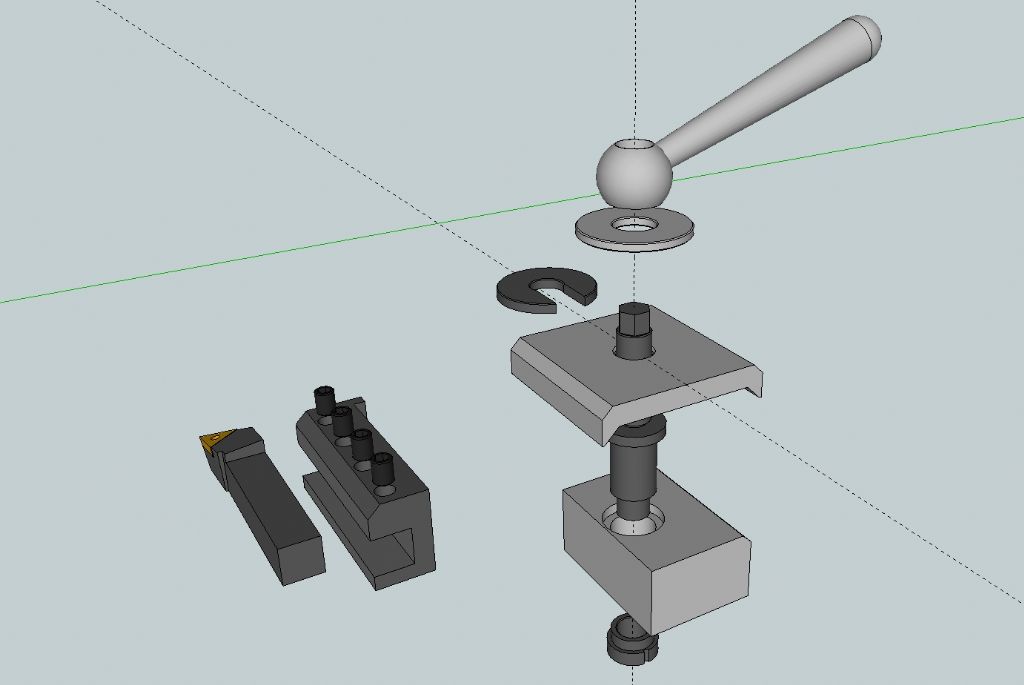

The tool holder adjustment is not done like the Aloris, Dickson, Norman with set screws. Actually there's no adjustment as the tool holder will be machined to the correct center height straight away. As the tooling is insert tooling the center should be always the same for that particular tool in it's holder.

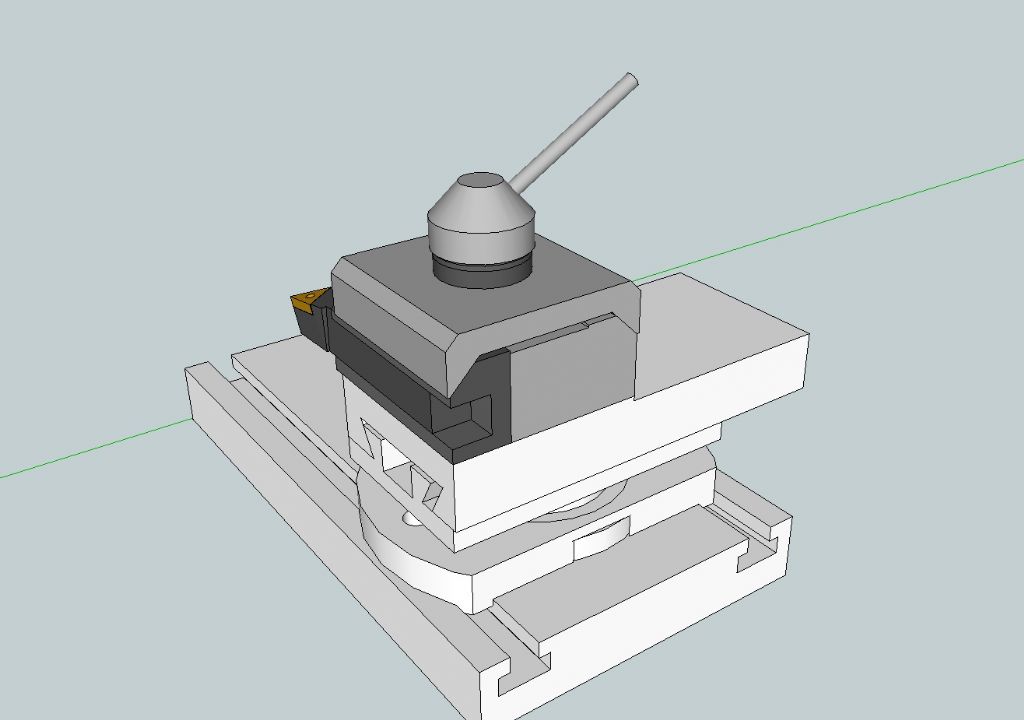

Hi Bob, well spotted, the rods can either be spot welded to the top plate or with adhesive. It makes no sense having them running around.

With regards to tool height adjustment, as I mentioned in my original post, I will be using insert tooling. My plan is to make a batch of holders to a standard size, and then machine the bottom surface to obtain the center height for that particular tool. As it's insert tooling once the height is set (by machining the bottom face of the holder) there is no need for further adjustments in the future. This will obviously not work for HSS tooling.

Not sure what the Norton design is, but if you're refering to the Norman tool post, the tool holders are quite large compared to this, less material required, less machining required, and I think this may be more rigid.

Posted by JasonB on 28/08/2019 18:39:59:

Think I would have some way to index the in/out position of the holder so that if you were doing a batch of items that needed a tool change you could swap holders and be able to use the same handwheel settings rather than have to measure each time a tool is holder is changed. Would also stop the holder being pushed back towards you.

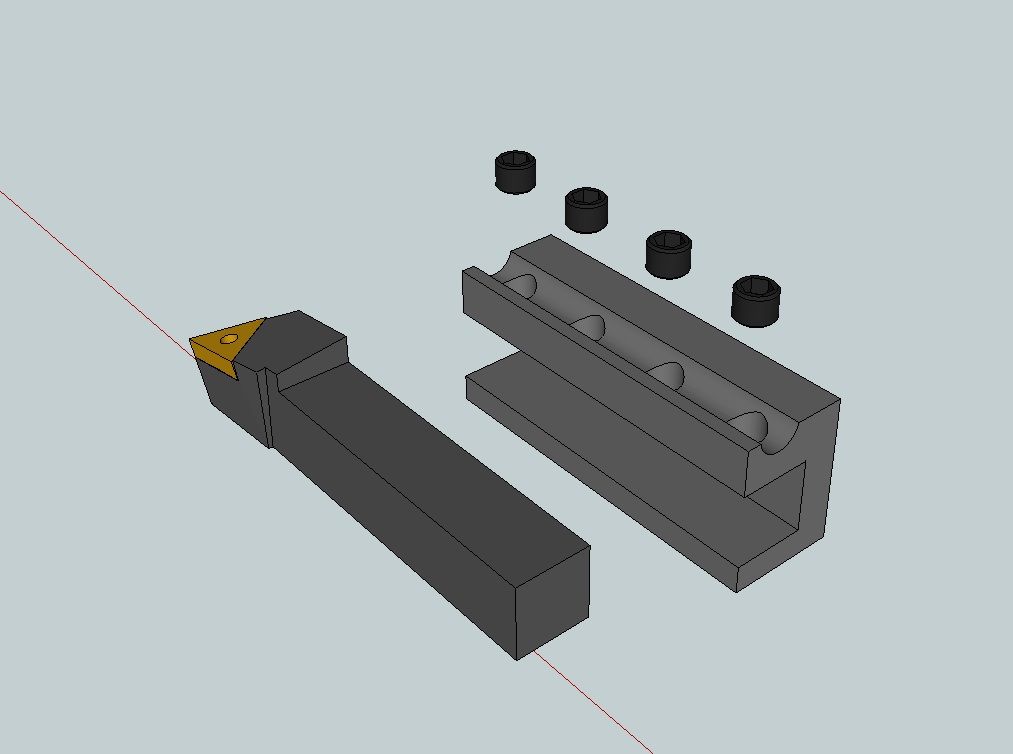

Maybe move the half round groove towards the middle so you have more thread depth for the grub screws

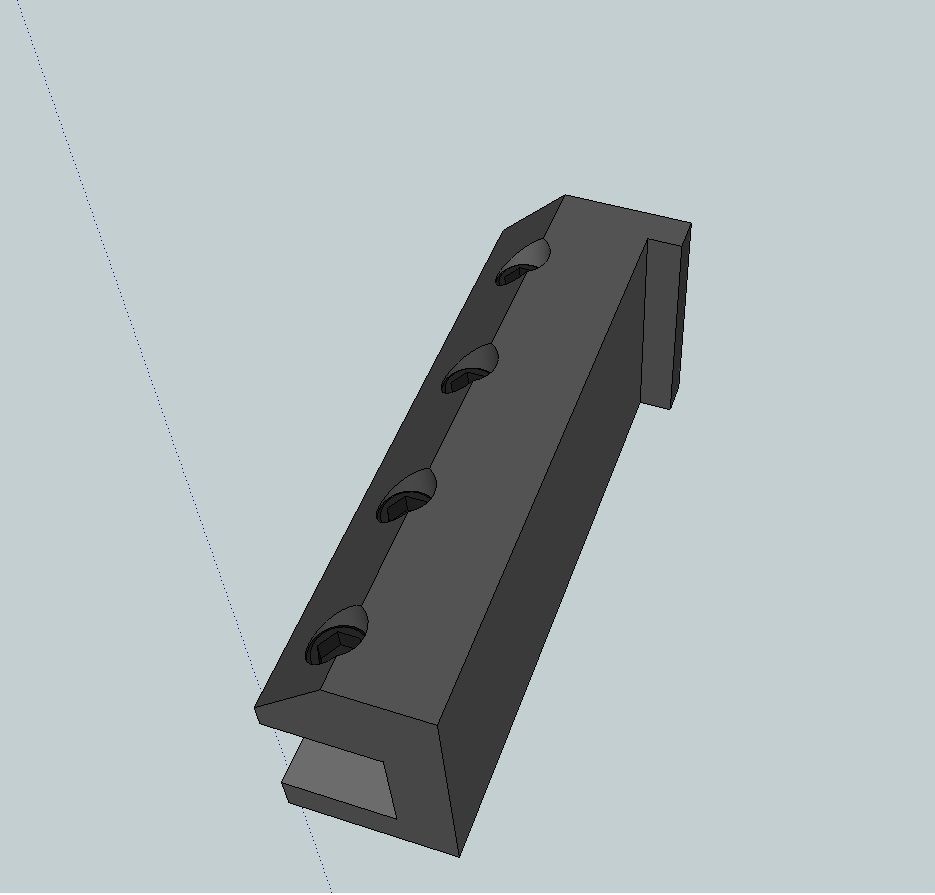

Good points Jason, Hadn't thought about indexing the holder, but that's easy fix, can be done. Regarding the round groove, I'm afraid that moving the groove further towards the center of the tool post will make the grip on the holder less effective. I could increase the thickness of the tool holder tho so Icould use longer grub screws. As is the screws are currently M8 x 6mm

ChrisB.