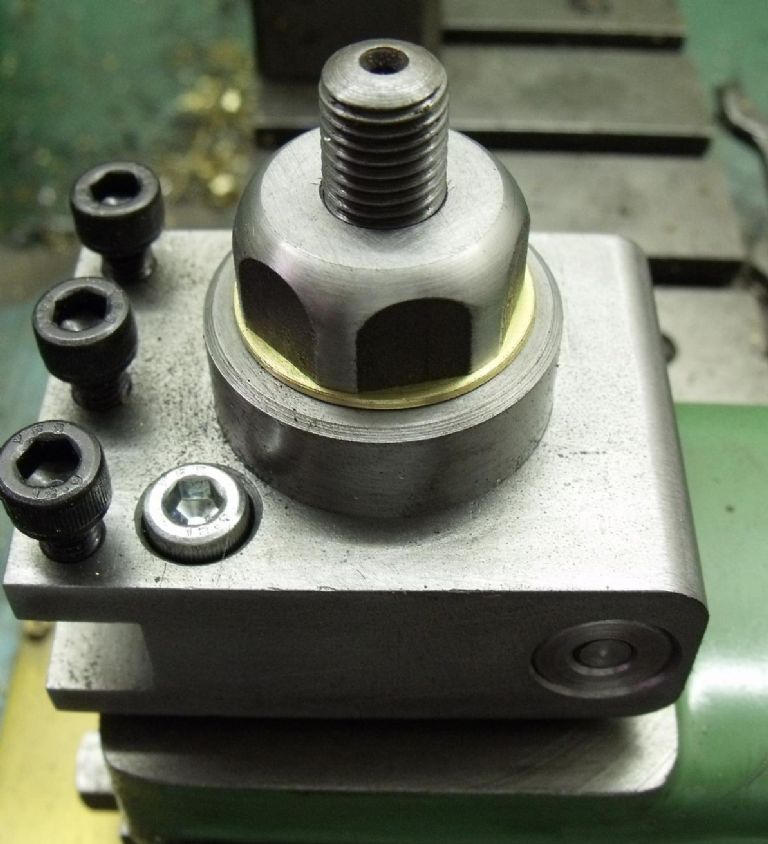

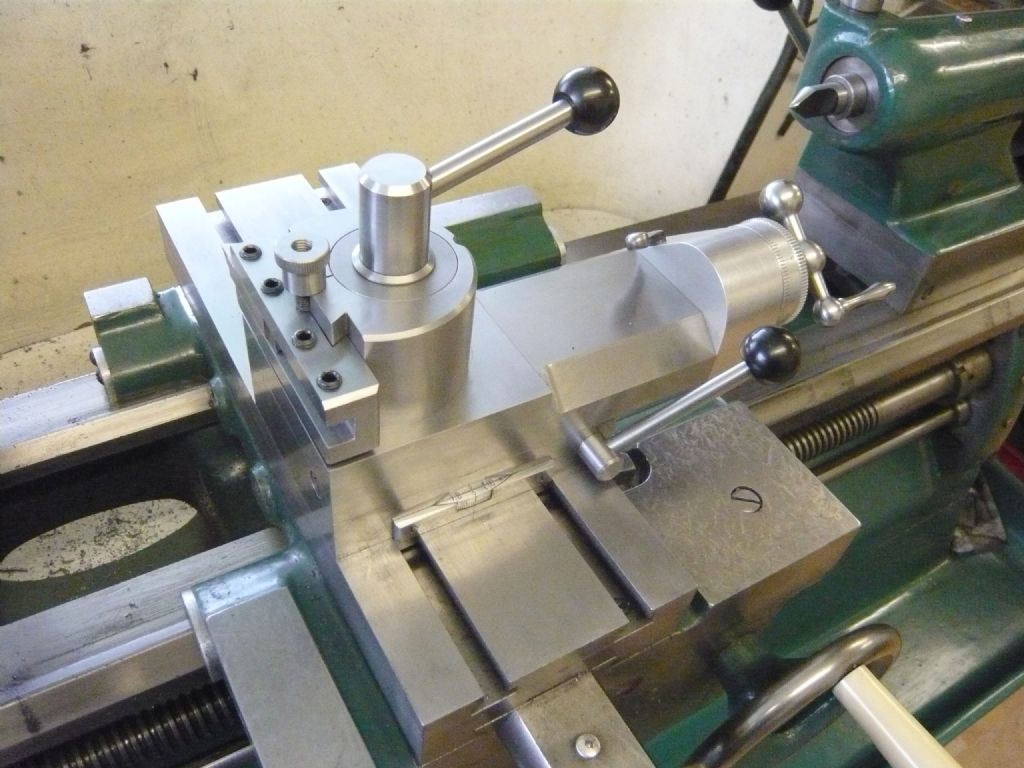

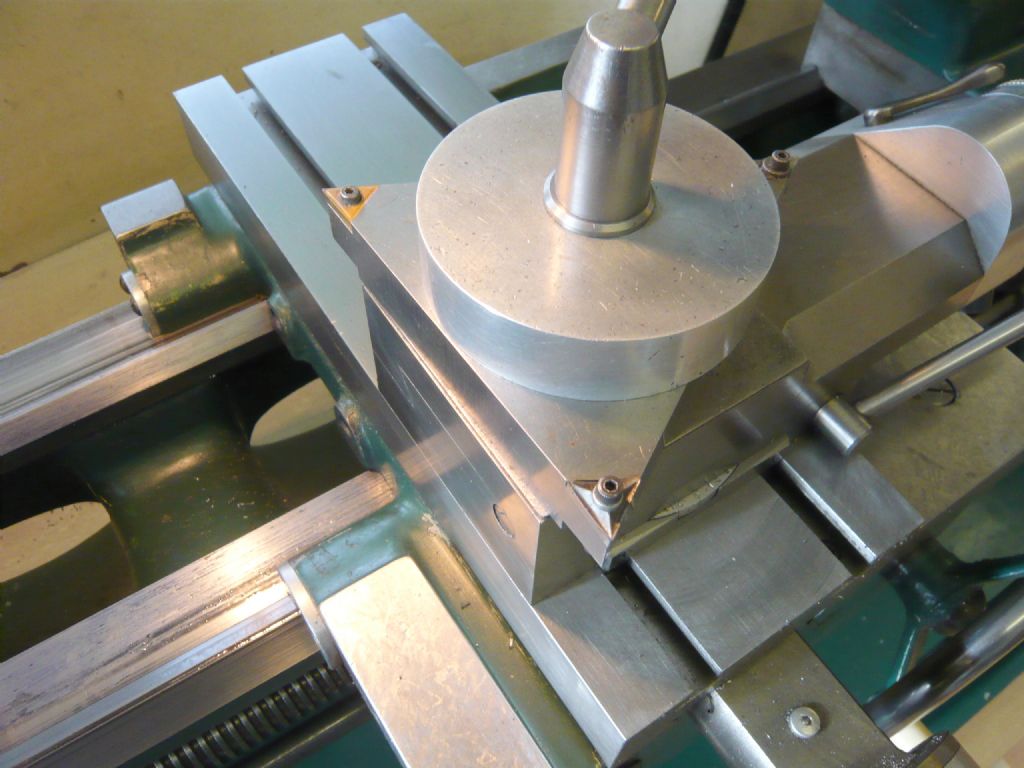

heres my take on the tool height dilemma

hope it make sense – for illustration only as you must check your own dimensions

so with the desirable and plentiful 12mm holder you can

a) skim 2mm off the holder base (or part skim as suggested leaving a step on the overhang)

b) Skim the top of the topslide – but then the 4 way block will be wrong and you will need shims for a 5/16" hss

c) Make up a 4mm shim piece to fit under the holder and use the elephants foot

d) buy a new chinese machine and stop dickering around

What do you think

Obtw I have made the assumption that a 12mm holder will also mean the height of the tool tip – is this always right?

Another member mentioned the use a 16mm holder and doing some skimming to make it fit. According to my estimate it should fit as is under an elephant foot see below – pls advise as I dont have one of these yet and I was thinking of getting a set with triangle pieces (in fact it was steviegtr as above)

Edited By brian jones 11 on 10/07/2021 16:02:34

Edited By brian jones 11 on 10/07/2021 16:06:07

Kiwi Bloke.