Posted by Sam Longley 1 on 07/01/2022 09:57:13:

I would not bother with the QCTP. …

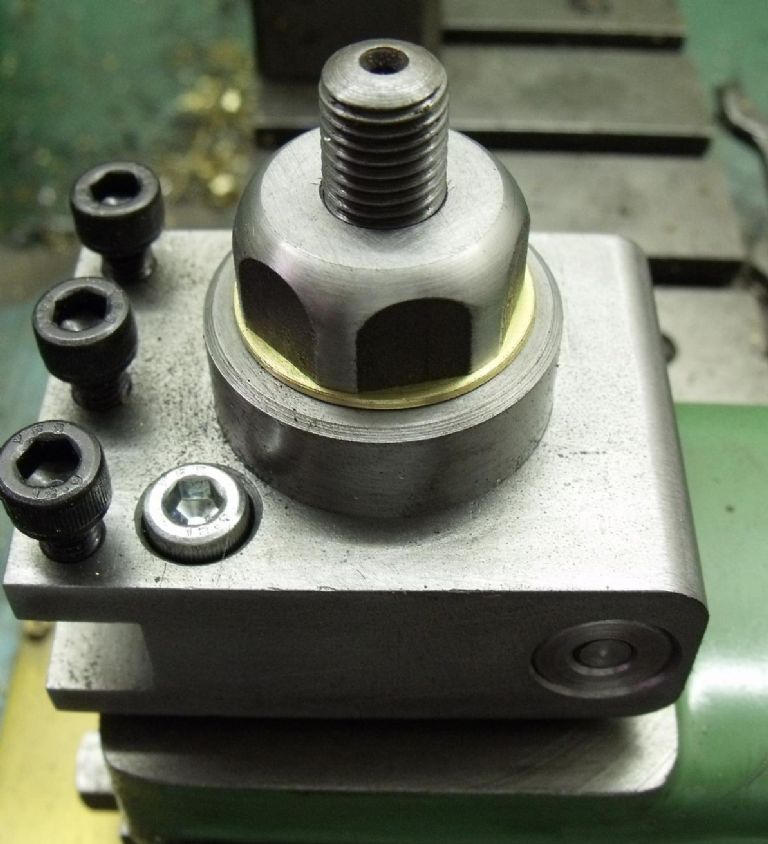

My conclusion too. QCTP provides Quick Changing and screw-adjustable height setting in exchange for some loss of rigidity and hard earned cash. (My darling precious spondulicks, I love them so much, sob…)

But as always, the value of a tool depends on what you do.

My feeling is QCTP are good for work-flows in which tools are swapped frequently and the operator likes to get on. They're particularly useful in an HSS shop, because HSS has to be resharpened. Sharpening moves the cutting edge slightly, making it necessary to adjust the tool height slightly, which the cartridge's adjuster makes easy.

QCTP are much less popular in industry than they were, and some of the reasons might apply in a home-workshop too:

- HSS has mostly been supplanted by Carbide because Carbide being harder and more heat resistant can remove metal about 5 times faster. (With a suitably fast powerful machine!) Carbide's extra hardness is sometimes handy at home, for example it can machine HSS when a special HSS cutter is needed.

- Most Carbide is accurately pre-formed into an insert. A gigantic range of insert shapes are available, so industry can machine almost anything efficiently without wasting time. The amount of choice is liable to blow the amateur mind, but in practice a few shapes do what we need. Of the special shapes, those made for cutting threads are home-handy. The big advantage of inserts is there's no need to adjust tool height when the insert wears out, because the holder isn't moved: instead the insert is either rotated to present a fresh edge or replaced. And no-one wastes time and money sharpening HSS!

In my garage workshop, I've found it easier to get good finish from HSS, but this is at the cost of having to buy a grinder, learning how to use it, and then periodically stopping work in order to touch up blunt tools and reset them in the lathe. Also necessary to lubricate and cool HSS, which may not be necessary with carbide.

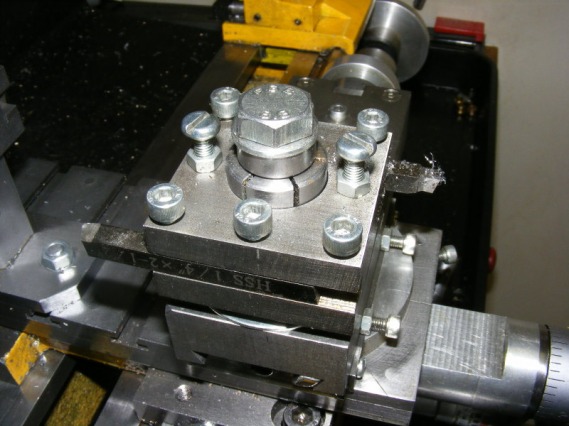

If I was sold on HSS, a QCTP would make sense. But I'm not! In practice, after getting used to the different speeds and feeds needed by carbide, I find inserts faster, more convenient, and mostly able to deliver acceptable finish. As I know in advance what combination of shims each holder size needs to put an insert at the correct height, it doesn't take long to swap tools in an ordinary 4-way tool-post, and the 4-way is stiffer than a QCTP. I keep meaning to mill several shims to the exactly right size, and they could be glued to the holders, but it's not been worth the effort.

In a race, I'm sure a QCTP fed with pre-sharpened pre-set cartridges would be faster than me fiddling with screws and shims. But, I suspect the insert/4-way system would faster in the long run because HSS/QCTP suffers a major delay whenever HSS has to be reground. And, in a race to remove metal, carbide cuts metal faster than HSS.

Using carbide Inserts in a QCTP rather than HSS might be a good idea because inserts avoid regrinding delays, but the tool-post being less rigid would limit carbide's effectiveness. Which is to be avoided because carbide performs best cutting deep and fast: it needs a rigid tool-post.

In conclusion, I suggest the answer to QCTP versus conventional isn't clear cut. It depends! I decided to stick with a 4-way. It hasn't stopped me doing anything or slowed me down significantly, so I got that one right! I'd cheerfully invest in a QCTP if experience had shown tool-changing to be a problem in my workshop, but it's not. My advice is to do a few months work before deciding. There are always other tools to spend cash on – a DRO might be more productive than a QCTP…

Dave

John Baron.