# The Great Shrine to Bling…

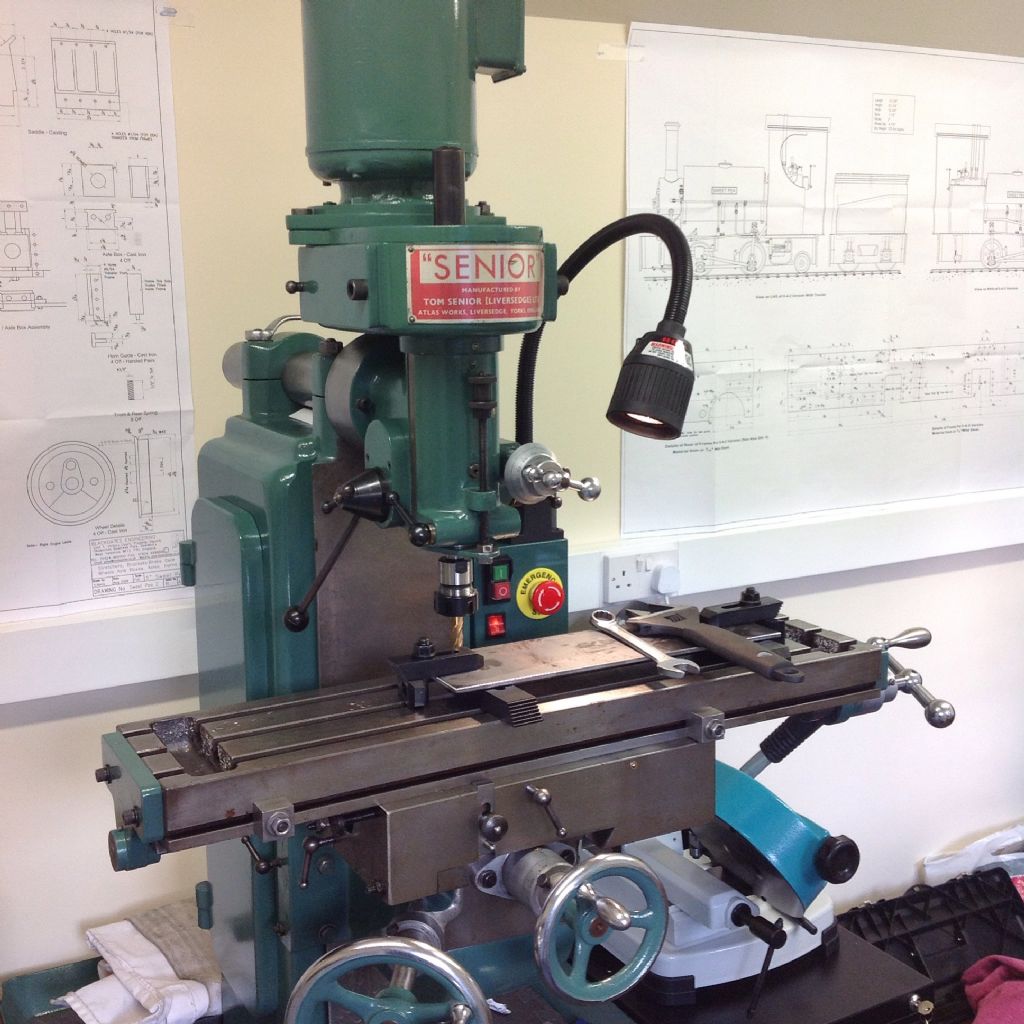

# Is there a Concors D'elegance class for post WWII original British milling machines?

# The grey one in the above pic – looks nothing wrong with that to me.

# The original TS green restored one in the above pics – i'd be too scared to use it and get it dirty. Presumably photos taken prior to useage…

# As per my previous post, whilst the thing is in pieces prior to repainting, i'd have got some keyways machined and fitted to the clamp castings and a long keyway machined on the ram for keeping tram and being able to move the ram further forward to give you a larger work envelope for that odd big job.

# My M1 unfortunately has the S head fixed to the Z dovetails, and for boring out bearing housings on m/c wheels etc, i run out of room. I've done disc brake mount mods on a 17" wheel rim, just, with difficulty, and one day, will get round to making an adapter for the head where i can fit in a 19" wheel on a table extension,and do brg housing mods without dismantling the wheel.

David Bacon.