ETW was confident enough to have solid crankshafts in most if not all of his IC engines? – but i don't see how that relates to whether or not you use CNC.

As for name changes – well 'the hobby' (or 'hobbies' will be called whatever the people doing it want, there's no regulatory body.

will be called whatever the people doing it want, there's no regulatory body.

That said, my assumption was that the term Model Engineering owed its popularity to the influence of Percvival Marshall and his publication.

Google's ngram viewer suggests otherwise:

Looking at the details, though, this is from a very small sample. Most examples from the mid-19C use the expression to mean 'a good example' such as:

"Here comes Martin, the model engineer, in a lovely state," said one of the men. " Drunk again !" (1868).

That said, there is firm evidence for the term referring to making models before then.

In an 1874 book I found an ad for "The Model Engineers' Handybook", which is "A Practical Manual on the Construction of Model Steam Engines." The 1902 Seventh Edition is readily available if you google its title – there must have been quite a demand for this book!

Of course, as soon as people started selling machinery, salesmen needed models as they could hardly cart around a full-sized beam engine to show a prospective customer.

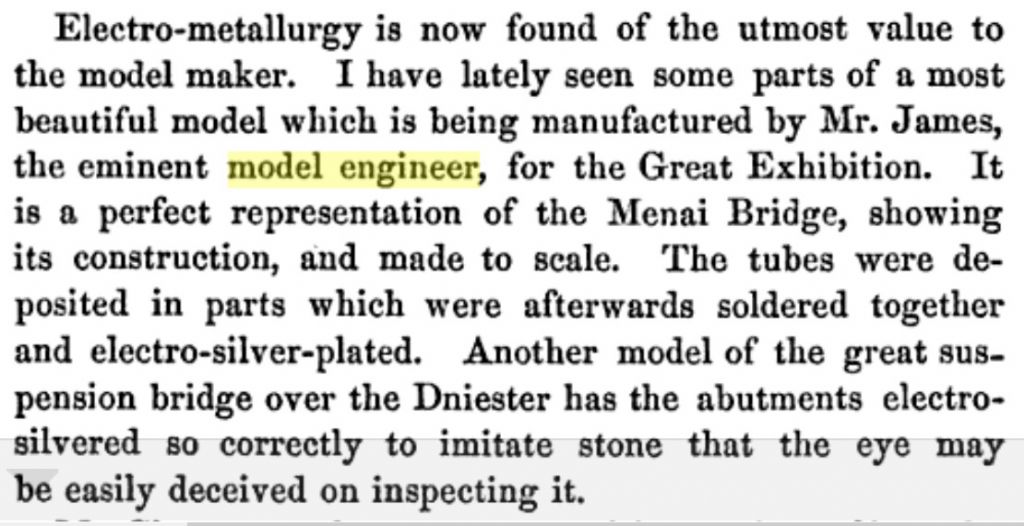

This 1851 passage by Alfred See (sic) not only shows that a model engineer made models then, but that it was both a profession and the use of advanced modern techniques rather than handywork to speed things up is not a new phenomenon:

Mr James' eminence suggests that 'model engineers' were a well-established profession by then!

In the absence of any real research, might I venture that model engineering started in this way as a specialist skill complementing the work of full size engineers. As the making of scale models spilt over into practice jobs for apprentices and then became a hobby for this working on full size machines and interested amateurs, it's natural that the name would be used.

Percival Marshall (and before him Paul Hasluck) popularised the word, no doubt. The very broad church that was The Model Engineer and Practical Electrician must have been the main influence on the definition of the hobby in the early 20th Century – focused on live steam but encompassing all aspects of the construction of small mechanisms in the home workshop.

I am sure Percival Marshall would be totally confounded by this hand-wringing about CNC. He enthusiastically embraced any new technology as it appeared and actively encouraged experimentation. I'm sure he would have seen CNC as just another box of tricks to use in the hobby, not an existential crisis.

From my own perspective, I don't see CNC as a threat to anything – it's just another example of how our hobby reflects full size practice.

Surely what matters to the future health of our hobby is encompassing as wide a range of engineering approaches, subjects, materials and skills as possible?

Neil

<reduced size of iframe>

Edited By Neil Wyatt on 06/01/2016 08:28:33

ega.

will be called whatever the people doing it want, there's no regulatory body.

will be called whatever the people doing it want, there's no regulatory body.