Cutting Metric screwcutting or tapping sizes is easy.

The Tapping size is (Nominal size – pitch ) so your 24 x 1.5 requires the bore to be 22.5 mm

You can make the parts in which ever order you like. having produced one thread, the component can then be used as gauge with which to assess the other part..

Possibly, in this case it might be easier to turn the material to 24 mm diameter and then to cut the external thread by applying a gradually decreasing cut until full thread depth is reached.

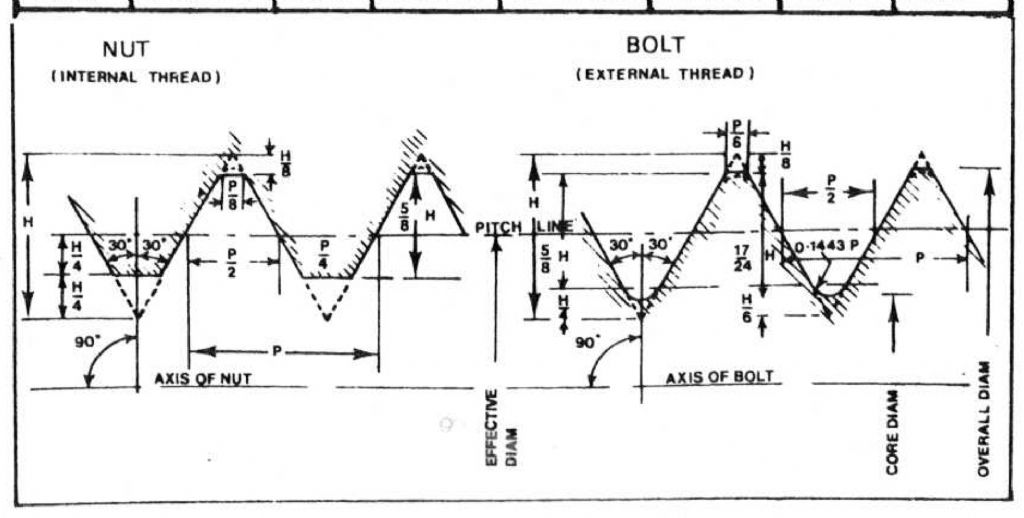

Zeus charts state that the depth for 1.5 mm pitch is 0.9202 mm with a flat of 0.1875 mm. This would give a root of 22.5346 mm. So 22.5 mm should suffice for the bore before screwcutting.

0.0346 mm difference is only 0.0014 inch in old money, so within a fairly tight tolerance.

When you choose to cut the external. thread, you may wish to turn the diameter slightly undersize, to produce a flat on the thread, but do not forget to make allowance for that when setting the final depth of cut, so that you not plunge in too deeply. Again, work on the basis of the root diameter being 22.5 mm. So the depth of cut, once the tool touches the work, will be less than 0.920 mm

The flats on internal and external threads will prevent any interference.

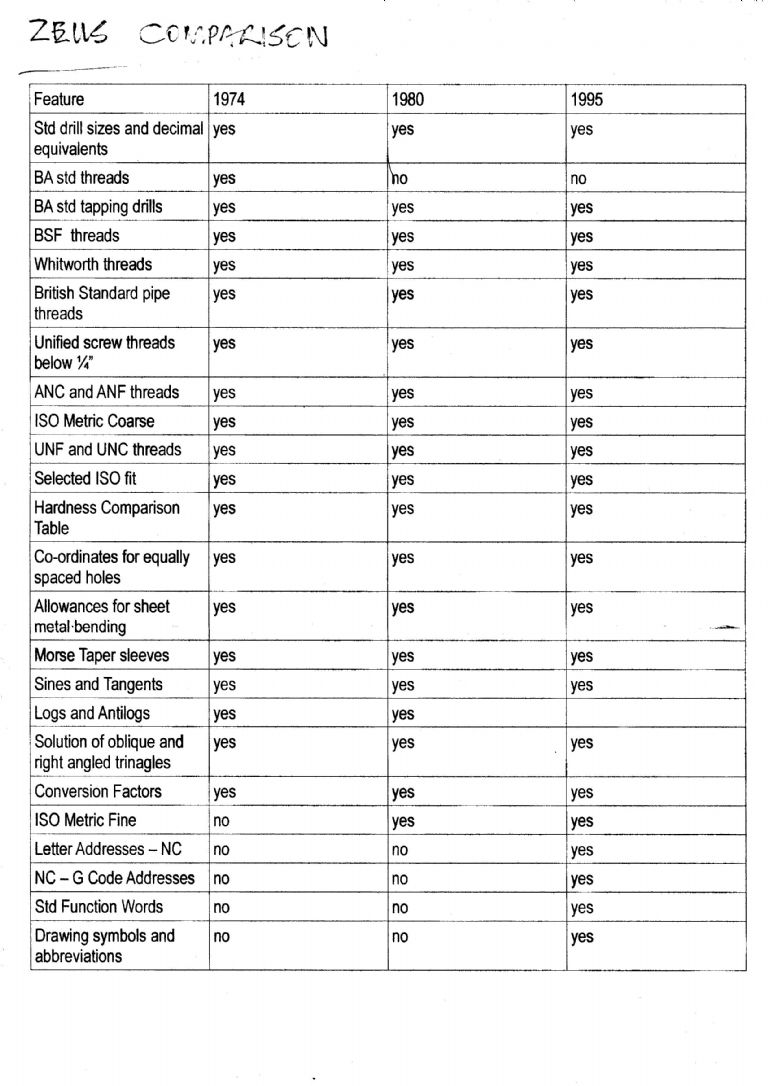

If you do not have a set of Zeus Charts, buy one. You will find the booklet to be a mine of information on threads, metric / Imperial equivalents, bending allowances for sheet meta (and sizes ) as well as details of Morse tapers, and trigonometric and log tables. My set bought in 1958 are grubby but regularly used!

One the various books on Model Engineering that you will find to be an invaluable reference for guidance and information when you need it. (I have quite a library, not including, by any means, all the titles available )

Normally with plain diameters it is easier to produce the bore first of all, and measure it, because it will be easier to turn the external diameter more easily.

Boring tools tend to spring, so just below the required bore size, you can take a number of spring cuts, without altering anything, and the tool will still be cutting; but less with each spring cut

The same will probably be true for cutting the internal thread..

HTH

Howard

Martin Connelly.

Martin Connelly.