Thoughts on Detecting Pendulums!

Thoughts on Detecting Pendulums!

Home › Forums › Clocks and Scientific Instruments › Thoughts on Detecting Pendulums!

- This topic has 66 replies, 12 voices, and was last updated 3 October 2024 at 00:40 by

S K.

-

AuthorPosts

-

25 May 2024 at 17:51 #732429

SillyOldDuffer

Moderator@sillyolddufferCarl W’s “New Clock Maker” thread, #731352, started a discussion about the merits of Hall Effect Device versus Optical Detectors, which I thought worthy of some research.

A Hall Effect Device (HED) detects a magnetic field, such as a tiny magnet glued to a pendulum bob, whereas an optical sensor detects the breaking of an Infrared or visible beam of light as the bob swings. Other possibilities include inductive, capacitative, and disturbance of an electrical field by the bob in some way. A fairly popular method detects the current generated in the impulsing electromagnet coil as a bob mounted magnet flies past, and uses it to pulse the electromagnet. Only needs a couple of transistors.

The ideal detector is triggered instantly by the pendulum at exactly the same point in it’s flight, and this isn’t easy to engineer. Preferably it should avoid power supply and logic level conversion problems by working at 5V or 3.3V. Of these systems the Hall Effect and Optical methods are probably the easiest to build, but neither is foolproof.

Reading a selection of specifications I found most HEDs are slow operating, between 50Hz and 3000Hz (20mS to 0.3mS) which suggests they will cause significant detect errors, not much better than a mechanical switch, though less intrusive. Another problem is that magnetic fields are not sharply focussed unless the detector and magnet are very close, less than 2mm apart. Although possible to focus a magnetic beam electronically, quite complicated! There are HEDs which respond at microsecond speeds, but they’re not cheap, and have to be operated very close to the magnet. The specs suggest ordinary HEDs are fine for RPM counting and door switches, but inferior to optical sensors when speed is of the essence. In a 1 second pendulum, a 10uS detect error could translate into a 10ppm deviation, which is far from bad, unless it’s the main source of error and can be fixed with a better sensor. I’ve gone off using a HED to detect where the bob is in a clock, mainly because their precision is doubtful.

Optical sensors come with their own problems. They are often sensitive to ambient light, diffraction and reflections, and prefer a sharp beam, typically requiring collimation with a lens or slots. A sharp beam also has to be well-aimed, making the detail design a little fiddly.

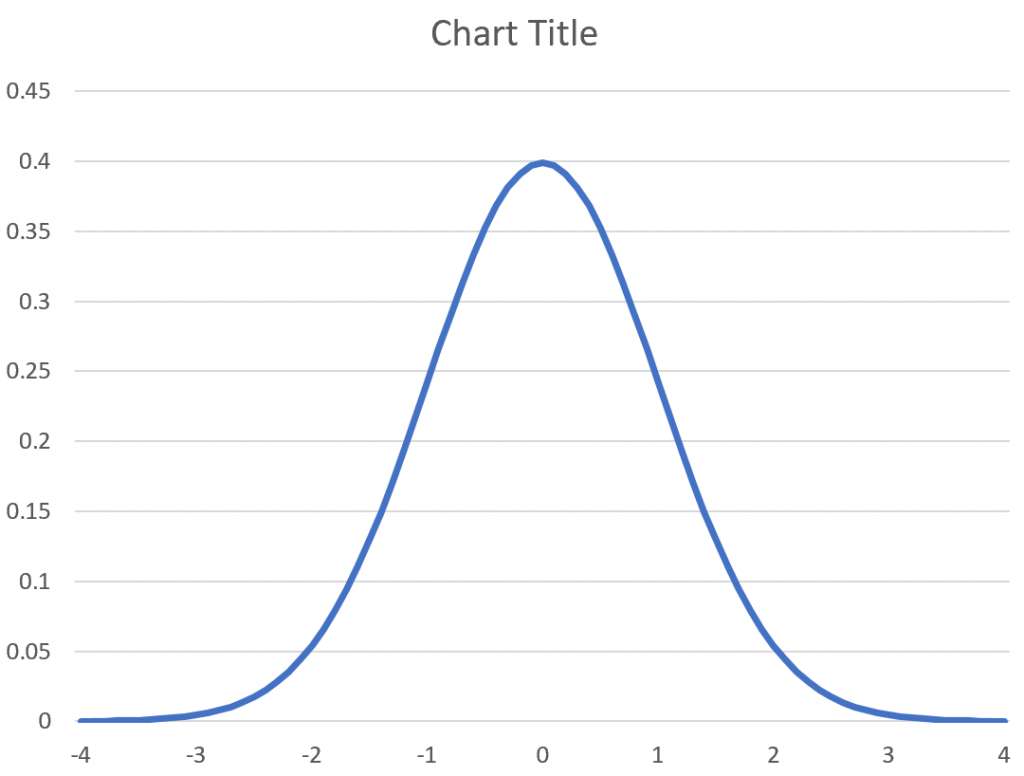

From a raw sensor of any description, one would expect a bell-curve transition. The sensor starts to see the bob at low level some time before the peak, and can still see a diminishing signal for about the same time it took the signal to peak from nothing.

This begs the question, where is the best place on the bell-curve to trigger? Not sensible to trigger when the signal is very low, down in the noise, nor is it easy to detect a peak in real-time. The usual arrangement is to trigger at some fixed point on a rising or falling slope, perhaps 33, 50 or 66% of peak. Higher settings tend to blank out noise, and give the signal time to stabilise.

Another way of reducing trouble due to changing ambient light is to modulate the IR beam, and only trigger when the modulation is detected. This is a common built-in feature in many components, but I think best avoided. The beam is usually modulated at 38kHz, introducing a potential quantum error in units of 0.026mS, and although the detector won’t be triggered by sunlight alone, the 38kHz decode will be delayed until the signal is strong enough to blast past ambient. Although better than a mechanical switch, considerably inferior to an unmodulated detector operated in the dark.

I made a mistake in my clock! Looking to use only off-the-shelf components, I selected the cheap HW201 Arduino module as a short-cut. It contains an IR LED, phototransistor, sensitivity adjust pot and a comparator to clean up the output signal, almost ready to go. However I had a lot a trouble getting it to work reliably, and have only just realised the problem still isn’t fixed because the comparator circuit is too simple. At the very least it needs an extra 10M resistor, see ‘adds hysteresis’ on the diagram:

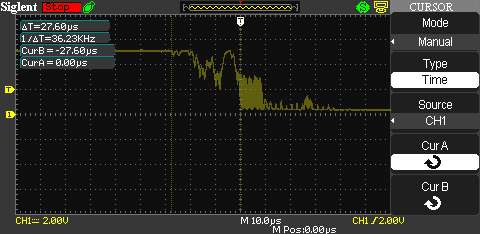

The HW201 circuit is arranged such that the output flips between 0 and 5V whenever the output of the phototransistor rises or falls below the sensitivity voltage controlled by the pot. Not good enough! As the noisy real-world phototransistor output traverses the trigger voltage, rising slowly at bob speed, about 0.1m/s, the much faster comparator flips rapidly between on/off, creating a shower of spikes over a very short period of time, only one of which gets through randomly as the trigger. My electronics are faulty. The cure is to modify the HW201 circuit by adding a 10M ohm feedback resistor between the comparator’s output and it’s + signal input. Then, the first decent spike during transition should be reinforced by the output, causing a clean flip. Oscilloscope traces show the difference, first without 10M feedback at high speed to show the zigzagging.

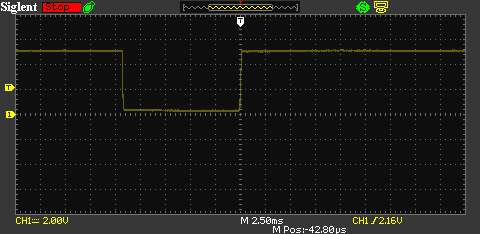

Next, cleaned up by 10,000,000 ohms worth of hysteresis:

My decision to misuse the HW201 without checking the circuit properly wasn’t smart, because this sort of mistake isn’t made by professional designers! John Haine recommends the Sharp GP1A57 opto-interrupter. The specification suggests this is a good choice, and buying one won’t break the bank, about £5! Typical rise time is quoted at 0.1uS, with a fall time of 0.05uS. The faster fall time suggests it might be advantageous for beam break detectors to trigger on falling edge signals. (True of other detectors: some are faster on rise, others are faster on fall.) The Sharp includes built in voltage regulation, which fixes another significant source of error, and a Schmitt trigger, but no lens. A potential gotcha is a warning in the blurb that the IR detector will lose about 50% of it’s power over 5 years, which is likely to shift the detect point. Nonetheless I spent a couple of hours on the web trying to find a better device without success. I finally bit the bullet and ordered a couple!

Have I finally cracked my clock problems? I doubt it! This is a voyage of discovery, and I think there is a lot more to say on the subject. As it’s entirely possible my summary above of detect methods is mistaken, grateful for any comments!

Dave

25 May 2024 at 20:02 #732456Anonymous

…this sort of mistake isn’t made by professional designers!

You said it!

The comparator circuit could be better. A good start would be to seperate the input signal and the hysteresis resistor. If the hysteresis resistor acts on the reference voltage potential divider rather than the input signal then it will provide proper hysteresis that is well defined. Having a 100n capacitor on the end of a 10M resistor isn’t exactly going to be a speedy circuit! It’s not clear why a 1k resistor and series LED are in parallel with 10k. The LED should be seperate from the function of the comparator.

I found the schematic a bit confusing, it is common to have a dot where wires join and no dot where wires just cross.

Andrew

25 May 2024 at 21:36 #732470S K

Participant@sk20060I do not believe Hall-effect sensors can compete with well set-up optical ones in this application, at least in general. But then most easily-obtained hall or optical interrupters are actually rather poor, being designed not for high-precision timing but for simple tasks like turning off a motor before a carriage strikes an end-stop.

Electronic noise is present always, and usually at about the same level regardless of where the voltage level is, including at the 50% point. Therefore, to minimize the time over which noise contributes to the uncertainty of the trigger, you should prefer as sharp (high dv/dt) a signal from the photodetector as possible. That’s usually found at the 50% point.

In some of my old experiments, I noted that the size of the photodiode itself is a serious concern when seeking high resolution. The reason is that the pendulum’s motion is rather slow, and as it sweeps across the beam, light impinging on the photodiode is being eclipsed slowly. This would show up as a ramp in the output of the photodiode, and a rather slow one at that. Even with the rather small ~1mm photodiode I was using, this slow ramp is quite significant. The longer and slower the ramp, the more that noise will contribute to timing uncertainty.

A very narrow slit or pinhole can be put in front of the sensor as a mask to constrain the light’s aperture and shorten the net sweep time. To compensate for the loss of sensitivity due to the mask, a stronger light source may be necessary. A beneficial side-effect of combining a mask with a stronger light is a reduction in sensitivity to ambient stray light.

Alternatively (I haven’t tried this), optics might be used to focus the light to a point. But that point should be focused to the blade of the interrupter (a thin blade would be preferred to a pin in this case), not at the sensor. You want the blade to have essentially zero transit time across the focused beam despite moving slowly. Further optics might then be necessary to refocus the light back to a spot on the photodiode, which then would not need a slit or pinhole.

So: use fast and low-noise electronics, a scheme that minimizes sweep time across the sensor to the degree possible (this is important), and probably a stronger light source.

25 May 2024 at 21:53 #732471S K

Participant@sk20060Another thought or two:

If you do use the Sharp, I recommend only using the faster falling edge for timing. But note that the fall time is only possibly, and not necessarily, strongly related to the timing resolution. The largest sensitivity in timing error likely precedes the output stage.

Unfortunately, you don’t have access to any of that to see, but you can test it to a degree by stimulating the Sharp with a pulse generator on the LED’s input. That is, connect a pulse generator producing fast rise/fall 5V pulses to the LED input so you can turn it on and off using the generator. The Sharp’s output should follow. Then measure the time between the 50% rise/fall of the pulser to the 50% rise/fall of the Sharp’s output stage. One will likely be longer than the other. Then, pay particular attention to the jitter in that timing. You want that to be minimized, as that’s all pure timing uncertainty. I’d mostly expect the faster transition direction to have lower jitter.

26 May 2024 at 10:13 #732534 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2I have used both hall and opto sensors in my day job. A opto will be much more repeatable than any hall device.

Similar to what SK has said, the optical arrangement is important. The Sharp sensor you are considering is electrically very fast but the optical setup is sub optimal for the application. The emitter – sensor gap is wide (10mm) as is the slit on the sensor (1.8mm). These mean that any lateral movement of the vane / flag (position between emiter and sensor) will vary the trigger point and ambient lighting is more likely to affect the trigger point as it is easier for it to reach the sensor.Something like the Omron EE-SX384 with 3.5mm gap and 0.5mm slit would be better optically dispite the slower switching time. It is consitency that is important, not absolute speed.

The reduction in performance of the emitter over time can be improved by reducing the current through the emitter.

The vane / flag should be as thin as possible to produce fast rise times. The edge of the vane / flag should also be parallel fo the slit in the opto for fast response. Bothe of these affect the rate of change of the light level as the vane / flag passes through the optical system. A matt black finish helps reduce effects of ambient light. Simple shielding helps with this too.

A rig to drive a proposed flag / vane / slot design slowy and precisely through the opto can reveal a lot. With an unconditioned sensor you can measaure the raw signal (a example of where an analog meter is better than a digital one). For a digital output sensor you need to control and measure the vane position repeatably. I’ve used a small lineal slide driven by a micrometer head (standard optical bench component) for this.

You could turn it into a science project / rabbit hole and automate vane movement with position measurement and plot operating point against it on a X/Y recording system (plotter, digital ‘scope, data aquisition system) all on it’s own.26 May 2024 at 11:20 #732545SillyOldDuffer

Moderator@sillyolddufferOn 25 May 2024 at 20:02 Andrew Johnston Said:…this sort of mistake isn’t made by professional designers!

You said it!

The comparator circuit could be better. A good start would be to seperate the input signal and the hysteresis resistor. If the hysteresis resistor acts on the reference voltage potential divider rather than the input signal then it will provide proper hysteresis that is well defined. Having a 100n capacitor on the end of a 10M resistor isn’t exactly going to be a speedy circuit! It’s not clear why a 1k resistor and series LED are in parallel with 10k. The LED should be seperate from the function of the comparator.

I found the schematic a bit confusing, it is common to have a dot where wires join and no dot where wires just cross.

Andrew

One of my few virtues is understanding my own limitations! In this example I know just enough about Op Amps to eventually twig that the HS201 off-the-shelf module isn’t good enough for my purpose. I also know that simply adding a 10M resistor to the module isn’t the best answer, but then I’m out of my depth. I don’t know enough to design a better circuit from scratch. Quicker, if I can, to cheat by tapping someone else’s talent, or by buying a better module!

Sorry about the diagram. I reverse engineered it from the board after noticing the HS201 circuit I found on the web omits the capacitors and unwisely specifies an LM358D op amp rather than a 393 comparator. Here’s a tidied up version. It’s drawn with a truly ancient UNIX utility called xcircuit, with a GUI that predates today’s ways and means. I like it because it only draws circuits, much simpler than modern tools with a component database and net facilities. It also supports the drawing conventions I learned 60 years ago, like U jumps!

Here’s a tidied up version:

My guess is the HS201 designer lifted the basic comparator from the datasheet which maybe had a 10k resistor from Vcc to output. Then someone decided it would be helpful to flash a LED when the output flips, and added a resistor and LED in parallel. The 358 circuit omits the 10k resistor and the output drives a ground connected LED/1k. Cheap and simple rather than precision.

I am embarrassed by this faux pas, but my whole clock endeavour is experimental! Let my shipwreck be your sea-mark…

Dave

26 May 2024 at 13:42 #732570 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2This is just another example of how bad these “maker” modules can be. And many suppliers blindly copy the mistakes of others.

Then there is the counterfit parts issue. A good clue is when you can buy a complete module for significantly less than the 100 off price for just one of the components. An example is the LM2956 regulator modules.26 May 2024 at 18:43 #732618 John PurdyParticipant@johnpurdy78347

John PurdyParticipant@johnpurdy78347Dave

Have you checked out the Honeywell SS440 series of unipolar HEDs? They come in various sensitivities, include a built in schmitt trigger circuit and have a switching time of 1.5 micro seconds. The ones I am using are the SS443 which typically operate at 125 gauss and release at 90 gauss.

John

26 May 2024 at 19:25 #732632SillyOldDuffer

Moderator@sillyolddufferDave

Have you checked out the Honeywell SS440 series of unipolar HEDs? …

I just did! They’re faster than the ones I found before. How fixed is the trigger point though? The spec suggests hysteresis over about 40 gauss, which could be a long time when a slow moving bob carries a powerful magnet past the sensor.

I think Robert is right: I need a rig to test some of these options.

I’m hoping to get some meaningful stats this evening out of my latest clock run, showing how much the trigger point of my current crude opto-sensor moves about. Previously I’d assumed all the variations I measured were due to mechanical error, on the basis that electronically detecting a non-intrusive IR beam break would be almost error free. Now I’m thinking the electronics are seriously error prone, which would doom my earlier attempts at precision compensation to failure; garbage in, garbage out!

But doing the job properly needs a rig, something hefty, where I can get under the pendulum with various sensors and make valid comparisons. The electronics clearly need more thought too!

Having to do it properly is unfortunate because my original goal was to get Shortt equivalent results out of a simple pendulum supported by cheap readily available hobby components, making it easy for others to try the same. Not working out that way – I keep being nudged away from shortcuts, back towards tried and tested best practice. Not given up yet though!

Dave

26 May 2024 at 21:18 #732647 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2Hi Dave,

For dynamic sensor tesing consider using a motor driven disk with multiple slots. This allows a faster repetition rate and easier analysis with an oscilloscope. Good for seeing effect of emitter intensity (current) etc.

Hall effect really is not suitable for this application it’s hard to arrange a rapid change in flux. In powered motion applications shaped pole pieces can be used but for a pendulum they will introduce a disturbing force. Any ferrous material moving near the magnet field will also do this.

Keeping the flux consistent is also difficult. Not because of magnet strength variation but because of geometry variations.Robert.

5 June 2024 at 06:18 #734181 John PurdyParticipant@johnpurdy78347

John PurdyParticipant@johnpurdy78347Dave

In an attempt to answer your question in your last post “How fixed is the trigger point”, I rigged up a micrometer stage from the carriage assembly from an old dot matrix printer, a micrometer head, and a .0001 dial indicator. I used one of my extra Honeywell SS443 HEDs, a 1/8″ dia. rare earth magnet (of unknown alloy), 5V Vcc on the HED and a 10K pull up resistor to the open collector of the HED output transistor. I ran 3 series of tests with the magnet spaced 1/16″, 1/8″, and 3/16″ away from the HED, each consisting of 20 trials. Before the start of each series, I did a few trials to find the trigger point and then set the dial indicator to zero and used that for the reference point of the 20 samples.Here’s the set up.

Here are the results:

1/16″ gap 1/8″gap 3/16″ gap

-.00011 .0001 -.0001

-.00009 .00002 -.0001

-.00002 .00002 -.0004

.00000 .00004 -.0003

-.00002 .00000 -.00035

.00002 -.00002 -.0004

.00002 -.00005 -.00035

.00005 -.00002 -.00035

-.00001 -.00002 -.00038

.00000 .0001 -.00035

-.00005 .0001 -.00028

-.00015 .00008 -.00025

-.00005 .00002 -.0003

-.00012 .0001 -.00038

-.0001 .0001 -.0004

-.00012 .00006 -.00038

-.00011 .00004 -.00042

-.00005 .00005 -.00048

-.00002 .00002 -.00048

-.00008 .00002 -.00048. 1/16″ 1/8″ 3/16″

Mean .0000505 .000038 .000347

1 sigma Std Dev .000057 .000047 .000105

2 sigma Std. Dev. .000113 .000095 .000210

3 sigma Std, Dev. .000170 .000142 .000316The stage could use some more refining as, although I have got rid of most of the sticktion in the movement of the carriage there is still some which makes trying to move the carriage fractions of 1/10ths a little hit and miss. Also, not helping, is moving it with the 40TPI thread on the micrometer head, it would be better if it acted on a 10:1 lever, as is it’s a bit touchy. Two things to address for further experimentation. If these two drawbacks were eliminated I feel the deviation would be even less.

What do the results show? If my calculations are right, for a gap of 1/16″ between the magnet and the HED the variation in the position of the trigger point was +/-.000057″ of the mean position 68% of the time, +/- .000113″ 95% of the time and +/-.00017 99% of the time. The figures for the 1/8′ and 3/16″ gap are as listed above for the 1, 2 and 3 sigma standard deviations shown. I appears that the 1/8″ gap gave the least variation.

John5 June 2024 at 08:13 #734202 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2Hi John,

Very nice work. I do have a couple of questiions. I’m not criticising your work, just tyring to understand the effects of all variables.

What type of magnet did you you use and what was the pole shape and size?

Was the pole movement passing (parallel to) or approaching the sensor face? (looks like it is passing)Do you have any idea how much the trigger point moved with a change in distance between the sensor and the plane of movement of the magnet? Changes in distance would be the biggest effect on the trigger point. There are two main reasons for this. Firstly pure geometry, the sensor operates at a given distance (all else being equal) so moving it in one plane will affect that in the other. Secondly the magetic field varies with the inverse square of the distance. This compounds the geometric error.

Robert.

5 June 2024 at 10:19 #734230John Haine

Participant@johnhaine32865I’ve been thinking about this issue on and off for a while, increasingly since this thread started. John’s measurements are very interesting – for the 1/8th gap sigma is effectively 1 micron. Given the limited number of points and the level of quantisation I suspect the 2 sigma and 3 sigma numbers are a bit suspect though! It would be interesting to plot a histogram of the points to see what the distribution looks like – when I did a similar exercise using my CNC mill as a stage for opto sensors it looked like the distribution was rather skewed. The opto gave about 0.15 micron sigma, roughly 10x better than these Hall numbers. I wrote this up for HSN and have put a copy of the article here

Depending on what the HED output is being used for it is also important where the device “untriggers” as the magnet moves away. My own measurements of an HED using my big mill with DROs fitted showed that the device had nearly 3mm hysteresis between “on” and “off” positions. If the HED output were used to impulse the pendulum directly through a magnet, if the HED package was on the vertical pendulum axis the impulse would be decidedly lagging; if offset to get a central impulse its phase would vary significantly with amplitude. By contrast the hysteresis using an Opto is very small. HEDs of course have the advantage of being insensitive to light.

Variations in the sensing point have different significance depending on what they are being used for. If they are just used for time monitoring it’s quite likely that for ordinary purposes variations are insignificant. On the other hand if they are used to drive the pendulum then they inject noise into the oscillator which is more serious.

I’m coming round to the conclusion that the best approach might be to use the sensor (a) to monitor timekeeping and (b) to unlock a gravity impulsing device, such as used on the Shortt/Synchronome, where the impulse timing is determined solely by geometry. Then the poorer accuracy and hysteresis of the HED will not matter and its insensitivity to light is a big plus.

5 June 2024 at 11:03 #734235 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattWhy not accept that each swing of the pendulum will time slightly differently?

You could use software or an analogue solution to keep a rolling average of the time and predict when to apply the next pulse.

Or perhaps the pendulum could somehow be incorporated into a phase locked loop?

5 June 2024 at 12:34 #734255 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2John H,

I think you may be over stating the slotted opto’s sensistivity to ambient light. Firstly they use infrared light so a lot of modern artificial lighting will not affect them. Additionaly it is relatively easy to shield the sensor from direct light.

Robert.

5 June 2024 at 13:08 #734262John Haine

Participant@johnhaine32865The Sharp device which many people use operates in the near infrared and has little or no filtering on the phototransistor. Adding a filter certainly helps quite a lot. The biggest problem I found was daylight, especially direct sun. Certainly better with a filter but still some effect.

Certainly one could discipline the pendulum to say GPS – this has been done.

https://dvaluch.web.cern.ch/hh3/

…though actually a caesium fountain clock not GPS. But that’s cheating!

5 June 2024 at 17:32 #734306 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2If the sensor if the slotted opto can be exposed to direct sunlight a shield or baffle will be required. If a thin vane is used to occlude the sensor this is not too difficult to arrange. Just a simple cover with a narrow slot for the vane is normally good for even direct sunlight. A simple shade is often enough.

Robert.

5 June 2024 at 18:27 #734316SillyOldDuffer

Moderator@sillyolddufferI’ve read John Purdey’s fascinating post and responses to it twice now, and it’s overloaded my brain! Not so much food for thought as a cornucopia; I’m stuffed!

Dave

5 June 2024 at 19:34 #734322 John PurdyParticipant@johnpurdy78347

John PurdyParticipant@johnpurdy78347Robert

To answer you questions, the magnet was an 1/8″ diameter cylindrical rare earth one and as I said, of unknown alloy. It was fastened to the carriage so that the S pole end moved linearly across the fixed HED as the carriage was advanced. The point at which the HED output switched low was noted, then the carriage was reversed and moved back away till the output switched back high. The process was then repeated 20 more times. The intent was to measure the repeatability of the linear position of the magnet relative to the HED where the HED switched state. Although not measured, as I had no way to adjust the spacing between magnet and HED in a controlled fashion, it was obvious that as the spacing was changed from 1/16″ to 1/8″ to 3/16″ the distance from the point at which the HED output switched to it’s low state and back to the high state as the carriage was reversed increased.

Out of curiosity I just measured that distance. At 1/16″, 1/8″ and 3/16″, magnet to HED spacing, it was .027″, .035″ and .060″, increasing non linearly as would be expected. This was only a couple of tries at each spacing, but they were within a thou of each other.

John

6 June 2024 at 11:39 #734412 John Doe 2Participant@johndoe2

John Doe 2Participant@johndoe2John Haine has already said it, but my feeling is that measuring and adjusting every individual pendulum pass with 100% or even 99% accuracy is simply not going to be possible – there are too many uncontrollable variables.

Therefore, as John H says, why not construct a circuit which keeps a rolling average. Every, say 600 seconds, the delta of the timing of the next pendulum pass would be compared with your atomic/GPS time reference. If the pendulum was early or late, the pendulum impulse drive could be decreased or increased by a tiny amount and then compared again 600 seconds later, and so on.

Would this also reduce pendulum measuring errors by a factor of 600 ?

You are never going to be able to make a pendulum swing exactly correctly on every single pass, but in the same way that UK power generation tries, (or used to), keep an average of 50Hz in every 24 hour period; you should be able to keep your pendulum timing between fairly accurate limits ?

6 June 2024 at 12:30 #734420John Haine

Participant@johnhaine32865Actually I don’t think I did say that! Synchronising a pendulum to an external source is relatively easy. The challenge is to make a pendulum oscillator which, without reference to an external time source, generates time with the best possible short and long term precision. The ultimate target is to make a clock whose timekeeping is limited by gravity variations – better than that we can’t do. Only one pendulum clock has really achieved that, a couple of others have come close.

Robert, I think the extent to which one can eliminate light sensitivity depends on your criteria. In my experience with adding a filter to the sensor and keeping direct light off the unit still results in a small sensitivity to light variations as they change the effective threshold of the detector. Having the vane run in a narrow slot is not so easy with a pendulum, they have an annoying habit of swinging in ellipses, and when started it is hard to avoid some back-and-forth swinging.

8 June 2024 at 06:49 #734741david bennett 8

Participant@davidbennett8Here’s no doubt a naive thought – how are we to judge a pendulum’s performance when it varies by local gravity variations, and an atomic clock doesn’t ?

dave8

8 June 2024 at 08:43 #734756John Haine

Participant@johnhaine32865By “without reference to” I meant without continuous phase correction.

8 June 2024 at 08:50 #734760 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133how are we to judge a pendulum’s performance when it varies by local gravity variations, and an atomic clock doesn’t ?

Nothing naive about that question, dave8

The success of our attempts to attain ‘Pendulum Perfection’ are absolutely limited to an envelope of physical reality.

The Atomic Clock effectively redefined the concept of Time.

Different games, different rules

MichaelG.

8 June 2024 at 10:17 #734780 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2<SNIP>

Robert, I think the extent to which one can eliminate light sensitivity depends on your criteria. In my experience with adding a filter to the sensor and keeping direct light off the unit still results in a small sensitivity to light variations as they change the effective threshold of the detector. Having the vane run in a narrow slot is not so easy with a pendulum, they have an annoying habit of swinging in ellipses, and when started it is hard to avoid some back-and-forth swinging.

Hi John,

All understood. Of course any movment transverse to direction of swing will also have a large effect on the operating point of a Hall effect sensor. This was noted, all be it with rough measurements, by John P.

Typically the removal of the effects of this sort of noise in optical systems would be to use a “lock-in” or syncronous detection methods. While this is not as complex or difficult as the manufacturers of ready made lab equipment, has limitations. While not so critical for analog systems, the carrier frequency affects the response time of a pulse detection system. for 1us resoltion you would need to use at least 3 MHz. This complicates matters.

An alternative approach would be to maintain a consistent ambient light level. There are two general approaches to this. First would be to monitor the photodetector current and maintain it at a consistent level with a feedback loop controlling the LED current. This could have a fast response and use a diferentiator to detect the flag passing or, probably better for this application, a slower response and a separate comparator for the flag.

The other approcah would be a separate detector and “flood” light source completely independent of the dendulum detector.Robert.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Clocks and Scientific Instruments › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

VFD Article in May issue 351

Started by:

Robert Atkinson 2

in: Model Engineer & Workshop

Robert Atkinson 2

in: Model Engineer & Workshop

- 9

- 19

-

22 April 2025 at 07:11

Michael Gilligan

Michael Gilligan

-

First 3D metal Printed Part

Started by:

JasonB

in: 3D Printers and 3D Printing

JasonB

in: 3D Printers and 3D Printing

- 12

- 19

-

22 April 2025 at 07:09

petro1head

-

Clarify some plain bearing engineering principles please.

Started by:

samuel heywood in: General Questions

- 12

- 19

-

22 April 2025 at 06:53

rjenkinsgb

-

Power tapping on the sx2p??

Started by:

samuel heywood in: Manual machine tools

- 3

- 3

-

22 April 2025 at 06:52

JasonB

JasonB

-

What Did You Do Today 2025

1

2

3

4

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 25

- 87

-

22 April 2025 at 06:36

Diogenes

-

Gas Engine Needle Valve

Started by:

Chris V in: General Questions

- 4

- 4

-

21 April 2025 at 22:55

Ramon Wilson

Ramon Wilson

-

Solar panel lighting problem

Started by:

KEITH BEAUMONT

in: Electronics in the Workshop

KEITH BEAUMONT

in: Electronics in the Workshop

- 5

- 11

-

21 April 2025 at 22:40

Howard Lewis

-

Hello from Sussex

Started by:

renardiere7 in: Introduce Yourself – New members start here!

- 3

- 4

-

21 April 2025 at 22:14

renardiere7

-

Motor to lead screw coupling method

1

2

Started by:

nevillet in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 17

- 28

-

21 April 2025 at 21:15

John Haine

-

Stopping milling chips going everyehere

1

2

Started by:

petro1head in: General Questions

- 20

- 32

-

21 April 2025 at 20:42

samuel heywood

-

Warco WM12 “flex”

Started by:

michaeljf93 in: Beginners questions

- 10

- 13

-

21 April 2025 at 18:33

JasonB

JasonB

-

Building Bernard Tekippe’s Precision Regulator

1

2

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 10

- 43

-

21 April 2025 at 18:24

gerry madden

-

One for the electronics enthusiasts?

1

2

Started by:

An Other in: The Tea Room

- 11

- 27

-

21 April 2025 at 17:25

An Other

-

Gear design

Started by:

John Haine in: CAD – Technical drawing & design

- 5

- 5

-

21 April 2025 at 07:53

jacques maurel

-

Lercanidipine

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 5

- 10

-

20 April 2025 at 21:25

JohnF

-

Generator size for vfd controlled 3 phase 5.5 kw motor

1

2

Started by:

PutneyChap in: Electronics in the Workshop

- 12

- 44

-

20 April 2025 at 16:20

Peter Bell

-

Stuart Twin Victoria (Princess Royal) Mill Engine

1

2

…

49

50

Started by:

Dr_GMJN in: Work In Progress and completed items

- 32

- 1,231

-

20 April 2025 at 15:26

Dr_GMJN

-

Motor bearings and more

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 7

- 21

-

20 April 2025 at 12:11

gerry madden

-

Newbie from the North West

Started by:

leakygasket in: Introduce Yourself – New members start here!

- 6

- 7

-

20 April 2025 at 10:46

JohnF

-

Air source heat pumps

1

2

3

Started by:

Plasma in: The Tea Room

- 28

- 64

-

20 April 2025 at 10:31

Martin Kyte

-

Acceptable feed screw backlash

Started by:

david newman 9 in: Hints And Tips for model engineers

- 12

- 14

-

20 April 2025 at 10:15

Graham Meek

-

Mounting chuck directly to rotary table.

Started by:

old mart in: Hints And Tips for model engineers

- 5

- 8

-

19 April 2025 at 19:43

old mart

-

Newbie Introduction – retiree in Gozo

Started by:

simon411 in: Introduce Yourself – New members start here!

- 2

- 2

-

19 April 2025 at 18:39

Harry Wilkes

Harry Wilkes

-

My week this week! My workshop videos

1

2

…

11

12

Started by:

Phil Whitley in: The Tea Room

- 14

- 288

-

19 April 2025 at 16:25

Phil Whitley

-

Change Wheels

Started by:

Julian Goodyear in: Workshop Tools and Tooling

- 6

- 18

-

19 April 2025 at 16:25

Nicholas Farr

Nicholas Farr

-

VFD Article in May issue 351

-

Latest Issue

Newsletter Sign-up

Latest Replies

- VFD Article in May issue 351

- First 3D metal Printed Part

- Clarify some plain bearing engineering principles please.

- Power tapping on the sx2p??

- What Did You Do Today 2025

- Gas Engine Needle Valve

- Solar panel lighting problem

- Hello from Sussex

- Motor to lead screw coupling method

- Stopping milling chips going everyehere