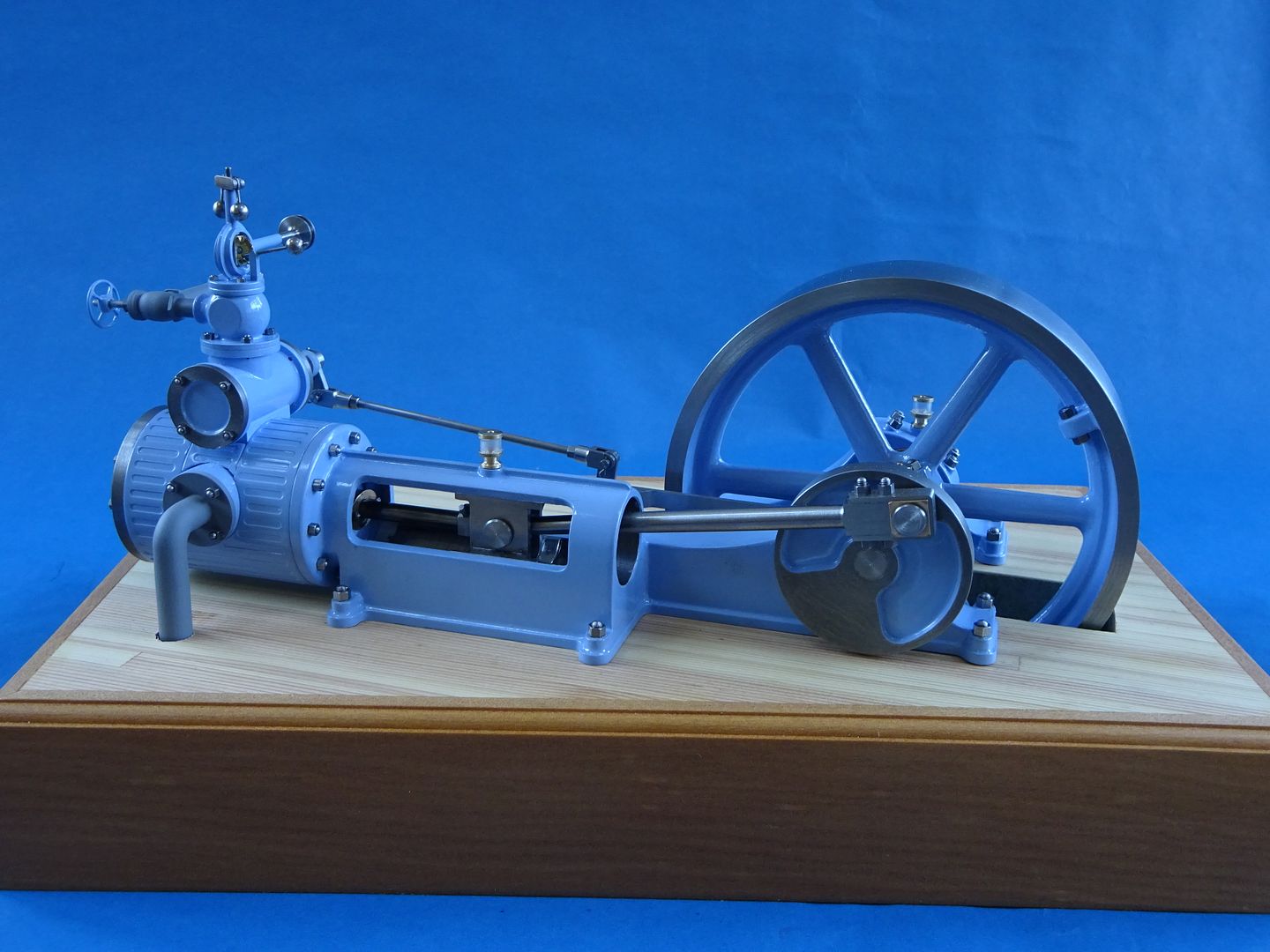

I suppose my Filer & Stow is not too far removed from the design usually associated with "Tangye" with a slightly different trunk guide.

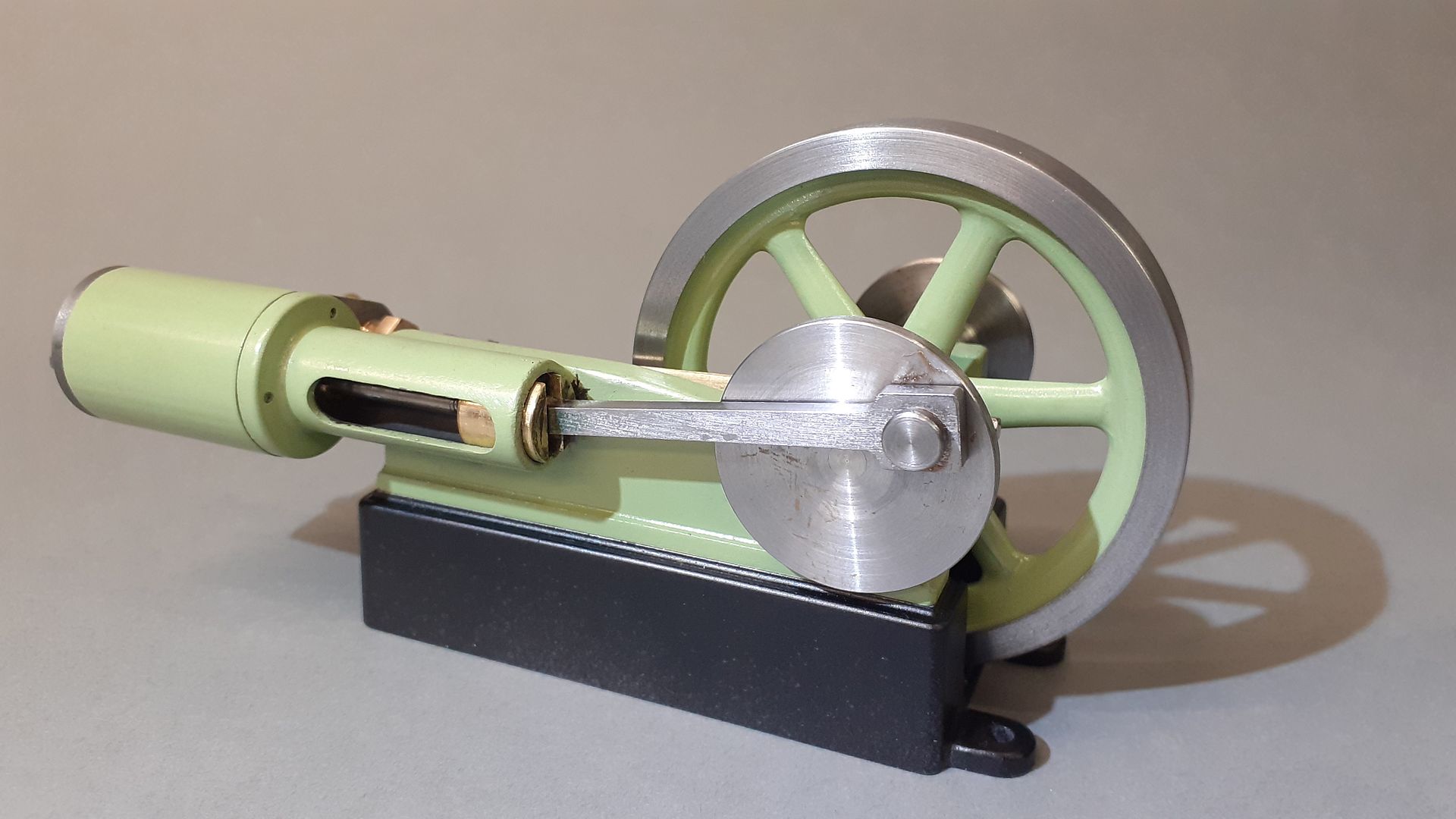

Or for a simple quick project my version of the Stuart "One One" is the same sort of layout. Bothe could easily be built as back to back pairs for that "Double Tangye" look

I do have quite a few images and details of the Tangye "Colonial" engine which is one on the to do list but not near the top

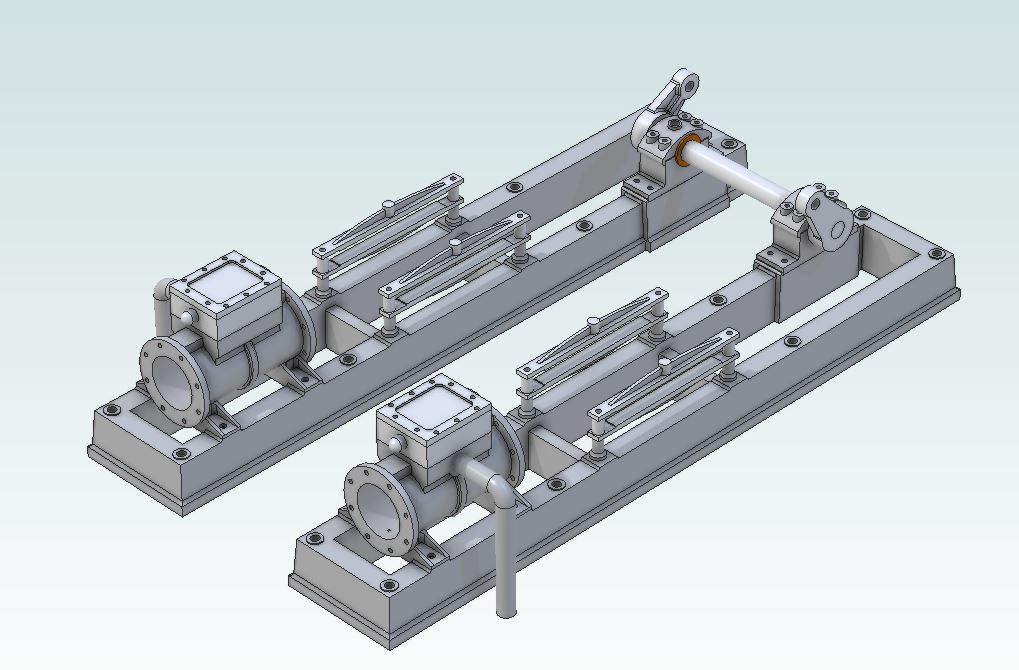

I did draw up a Victoria Look Alike to be made from barstock but ended up making one from a Casting Set with a few alterations, again could be made as a twin fairly easily just a case of pressing "mirror" on the CAD file

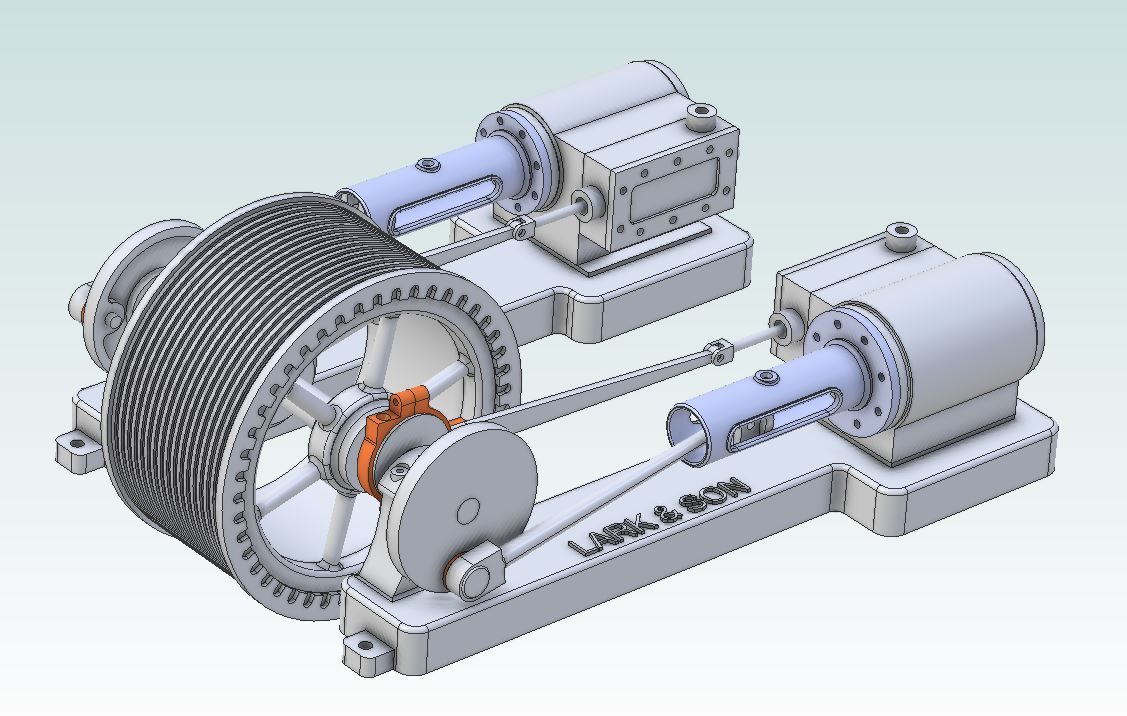

Or for a slightly simpler project a reworking of the Clarkson as the Lark and Son cross compound which could either be done by modifying the Clarkson castings or better still cut from solid

Bottle engines are nice and something to think about, should be interesting carving the bottle from solid. Probably have to split it in half horizontally so the insides can be hollowed out and then after joining cut the pockets in each side. The James Begg one that Anthony Mount designed was a nice engine but not available now that Cotswold Models are no more and I'm not so keen on the PM Research one.

paul rayner.