Posted by JasonB on 21/07/2022 08:14:46:

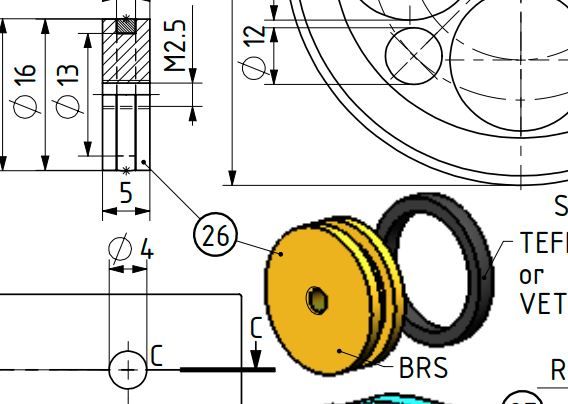

The usual way is to file or mill around the outside of the ring and then simply blend that into the shaft by filing. Chances of soldering all three together and getting the bore of the ring true to the flat face of the palm are slim.

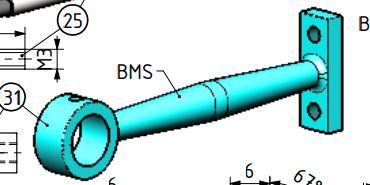

This shows how Stew Hart the original designer made that part…

I made mine the same way as Jason except I rounded the end by making this tool to hold the piece so it could be rotated against a spinning end-mill.

The rod was turned to make a step fit width and depth the hole drilled in the eccentric rod. The eccentric end was held in place by the mangled sacrificial washer which was turned to match the outer diameter of the ring and drilled to take a bolt tapped into the body of the rod. The whole was held in machine vice such that rotating the eccentric rold caused the end-mill cut a nice curve around the end.

I don't recommend the method and if tried approach with caution! Important that the milling cutter be a small diameter 4-flute type to reduce the risk of a grab, and only tiny conventional cuts taken for the same reason. The sacrificial washer bears the scars of a grab due to me trying a climb cut.

I show the item as an example of a tool made to achieve a purpose – to quickly machine mill round ends rather than manually filing them to shape with buttons or whatever. The tool did the job quickly and accurately with a good finish, but definitely a walk on the wild side. Having tried the experiment, I concluded the risk of this tool damaging me and the job is too high for routine use. This example was educational rather than practical, but I often make simple tools, jigs and fixtures to facilitate cutting.

Stewart's engine is a good beginner build because it has a few parts that make you think and develop new skills. I found the design to be a good balance of not too difficult and achievable challenges. Can all be done with a small mill and lathe, and the mill isn't essential. It maintained my interest throughout.

I remember my first encounter with BMS. Did it mean Bright Mild Steel or Black Mild Steel? On this engine either will do, but Bright being pre-machined saves time unless it warps due to a cut unleashing rolling mill stresses… Doesn't happen often fortunately.

Dave

Edited By SillyOldDuffer on 21/07/2022 20:42:47

SillyOldDuffer.