Thiel Nassovia vertical metal saw

Thiel Nassovia vertical metal saw

Home › Forums › General Questions › Thiel Nassovia vertical metal saw

- This topic has 40 replies, 9 voices, and was last updated 28 October 2024 at 07:26 by

Diogenes.

-

AuthorPosts

-

27 February 2024 at 18:53 #716539

Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234Hi,

For a long time I wanted to have a vertical saw to cut metal. I think I finally found a nice one:

Tomorrow morning I’m going to see it. It is supposed to be in good working order. What I have to check on such a machine? Besides obvious things like bearings, blade stability, signs o wear … I was never close to a band saw before 🙂

27 February 2024 at 21:38 #716560Diogenes

Participant@diogenesThat looks a nice saw.

Don’t forget to look underneath the table to check the lower guide assembly and tilt / lock mechanism.

Be sure to ask the seller whether there are any ‘loose’ spares / attachments / paperwork that are not attached to the machine or have become separated from it..

..envy..

27 February 2024 at 22:15 #716562 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234But why the grooves on the table are not parallel with the cutting direction? I can’t imagine a reason why they are not straight.

I found a video with a similar machine. It has a blade welding device on the left. It has even a small grinder! I start to like it even more.28 February 2024 at 07:03 #716608Diogenes

Participant@diogenesNot sure about the Thiel, but some of the bigger Startrites etc., were intended to be flexible ‘machining solutions’ in their own right, say for production & processing of things like die-blanks, housings, cast components.

Tables may tilt all ways, blades may be aligned to provide access to large components, or to be used with ‘band files’ or circle cutters etc.

It will be interesting to see what it can do, it might have capabilities beyond simply slicing up bits of stock..

28 February 2024 at 08:03 #716617DC31k

Participant@dc31kBut why the grooves on the table are not parallel with the cutting direction?

Why should the grooves on the table be parallel with the cutting direction?

What function do the grooves provide? Maybe lessening friction, maybe managing the swarf/sawdust that is produced.

You could think of a way that having parallel grooves might not be helpful – on narrow stock, the workpiece support would be less.

Have a look here at the Thiel die filers and note the tables thereof:

http://www.lathes.co.uk/thiel-produro/

What I cannot see on the picture is any fence or provision for fitting one. That is handy if you need a long parallel cut.

Some useful info. here (including English instructions for the welder in case yours are illegible or missing):

https://www.practicalmachinist.com/forum/threads/thiel-nassovia-bandsaw.400812/

Elsewhere, it may be known as a Thiel 18 (there is a model 17 that comes up and it not that one), so that might find additional information:

https://industry-pilot.com/en/wood-bandsaw-machine-nassovia-thiel-18/p103783

28 February 2024 at 13:39 #716662 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234Yes, that sound like a good reason for not having parallel grooves. Thank you for the links.

This morning I bought the saw! It is already at my house. I didn’t had much time to check it but it is more complex that I imagined. Because there is a pedal that can stop the blade without turning off the motor. There is even an oil bath! Mine doesn’t have that mini grinder like in the video above. In that place there is a small drawer that looks like an ash tray. I have no clue yet what is it’s purpose. It’s bottom can be removed so maybe its use is collect some swarf? Because it is placed exactly bellow the blade welding terminals.

The rubber on the wheels looks fine, just small cracks. It’s original color was green. I’ll remove the paint with a chemical paint stripper. And I’ll finally have an excuse to buy a spay gun and an air compressor. The saw it made from cast iron except the doors. They are made from thick aluminum. The blade is completely useless but nearby there is a company that makes custom size bimetal blades. I already saw that some repairs were performed inside. But nothing outrageous was noticed yet.But big surprise! The seller had also a FUS250 milling machine. This is exactly the model I just started to restore! He wanted to sell it also. But I didn’t liked how it was looking. It is in working condition but in my opinion it was abused a lot. He even switched the gears once without stopping the motor while I was watching!!! Now I’m appreciating more my machine. So I didn’t want to buy it. But before leaving he made a very good offer. The same price like the saw. And he added also a slotting head and a dividing head. These were the only accessories that were missing from my mill. And a box with HSS milling cutters that I can barely lift. Since I had the truck there I decided to buy it. It might be of some use for my restoration project. Anyway, this is going to be a busy weekend!

28 February 2024 at 14:53 #716672

28 February 2024 at 14:53 #716672 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133That looks a great buy !!

… I envy your available space.

MichaelG.

28 February 2024 at 20:30 #716758 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234Space is not the biggest issue. I’m more concerned about the weight. I don’t know how well the garage was built. If I keep adding heavy machines I might crack the floor or worst.

I made a few calls to sand blasting companies and to my surprise the prices are not so high. And they can come to my place. Tomorrow a guy will come to have a look. Sand blasting might be a better choice than paint stripper for such a large area.

I think that small drawer is meant to store some kind of flux for blade welding.

1 March 2024 at 11:15 #717107 Dave HalfordParticipant@davehalford22513

Dave HalfordParticipant@davehalford22513Look after that drive belt, they are quite expensive

1 March 2024 at 11:26 #717113 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234It is something special? It looks like an ordinary trapezoidal belt.

6 October 2024 at 20:26 #757682 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234A glorious new restoration project began today! I want to clean the band saw and to apply at least a primer before the winter comes. So I can move it in the garage to finish the rest.

I tried to remove the table but is too heavy to lift it alone. So I had to be creative to lower it into the wheelbarrow.

The table is not just a cast iron plate. It can be tilted and it has some kind of crude power feed.

I cleaned the red paint with the angle grinder and a wire brush. Unfortunately I can’t remove the upper wheel. The bearing does not come off the shaft. So I will have to remove the wheel together with the front/back tilting mechanism from behind the wheel. But I can’t hold everything with one hand and use the Allen key with the other. Is too heavy. This was a good excuse to invited a friend next week.

I’m not sure what to do with the bottom part. There is a lot of stuff inside and I would like to clean there. In my amateur opinion, this machine is severely overengineered. The motor has a few gears then some kind of continuous speed adjusting mechanism with a belt. Then a chain that goes to an oil bath and who knows what else. It has also a clutch and a brake I think.

But what bothers me most is that I don’t have good access there. I can’t remove the back cover because most of the stuff you can see above are attached to it! I’m still looking with a flashlight for a solution.

I removed the motor. After more than 70 years it deserves new bearings. But unfortunately when I measured it I found that one phase is dead. It has >40kΩ. The other two have 9Ω. Unlike the new motors this one has some kind of open structure. The fan is inside. The saw was used to cut also wood. There is a lot of wood swarf and the fan sucked it into the motor. And clogged completely the air intake. So maybe the motor cooked itself. When I tested the bad saw at the seller workshop it was working. But maybe it can run also with only two phases.

That is no big deal. I have a few suitable spare motors. I found that the cast iron body is actually made from two pieces. But I can’t tell how are they assembled together. They are not welded. And there are no screws.

This time I used a lot of labeled large zip bags for all small parts. After I finished the other milling machine restoration project I was left with some 2-3kg of screws, nuts and other small parts. I can’t remember from where I removed them 🙂

7 October 2024 at 07:59 #757741bernard towers

Participant@bernardtowers37738Thats what your phone or digi camera are for

7 October 2024 at 10:41 #757775SillyOldDuffer

Moderator@sillyolddufferA glorious new restoration project began today! …

…

After I finished the other milling machine restoration project I was left with some 2-3kg of screws, nuts and other small parts. I can’t remember from where I removed them 🙂

Oh dear, having a big bag of left over parts means Sonic hasn’t finished restoring his other machine yet! Re-assembly went wrong, a new problem that should be fixed.

Does it matter? No-one knows! For example, washers are often included simply to avoid damaging the paint work, in which case failing to replace them isn’t a worry. Often though, washers have an important function: spacing, anti-vibration, load spreading, improving the clamp, preloading, or providing a spring etc. Failing to replace functional washers, or using the wrong ones, can cause trouble later.

A particular evil is apparently minor assembly errors tend not to stop machines working, and all seems well during a quick test. Unfortunately the machine might not be working to specification, and/or the missing parts cause it to become unreliable over time. Worst of all, machines that start misbehaving several months after a rebuild can be a pig to diagnose when the cause is missing components. I would be extremely reluctant to buy a restored machine where inspection showed paint, polish and missing hardware. They suggest an unskilled restorer.

The easiest way to avoid trouble is to make sure the thing goes back together in the same condition it was before. Bernhard’s photo tip is good, on anything complicated I also use trays and a notebook.

Have to say I’m fascinated by Sonic’s version of Model Engineering! Clearly enormous fun and very interesting, but in a few weeks Sonic leaps from burnishing with carbide cutters. via cheapo grinders and unknown flea-market grinding wheels, to restoring a high-end industrial saw that’s in poor condition. That the saw’s been demoted to cutting wood at some point suggests wear and tear eventually made it unable to cut metal properly.

Sonic’s approach to tool buying wouldn’t suit me because I buy tools specifically to make things in support of my experimental interests. And progress is slow enough in my workshop without me messing with opportunistic bargains as well! So I can’t help wondering what Sonic’s workshop is for? His vertical band-saw was expensively built to do a lot of hard work, way over the top for most hobby workshops. Could be restored, but why? Will take time and money to do properly, and then the saw would have to be kept busy to recover the cost. My guess is that will never happen because Sonic enjoys organising and fixing tools more than using them.

All power to Sonic, and he’s not alone. Though not my cup of tea, it’s a respectable branch of the hobby. There’s much interest in exploring tools and getting junk to work again.

I thoroughly enjoy Sonic’s posts. Whatever the rationale, please keep up the good work.

Dave

7 October 2024 at 12:26 #757787 Sonic EscapeParticipant@sonicescape38234

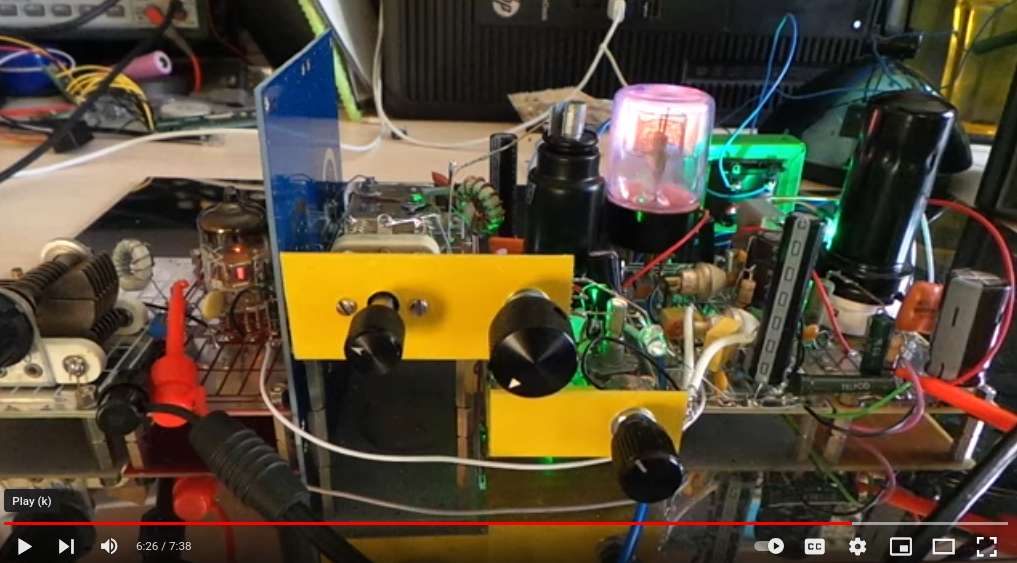

Sonic EscapeParticipant@sonicescape38234Well, my version of Model Engineering has little to do with the textbook definition of it. I wonder for how long I’ll be tolerated here. Sometimes I’m thinking on trying to build a small engine, maybe this one. And to connect it to a small generator to power some of my vacuum tube radios. That should be nice, the glow of the tubes and the noise from the engine. But not now.

All those different activities in a short period are cause by my very low tolerance to boredom. I must be always stimulated by new ideas, activities or at least good book. This is a great source of satisfaction. Sometimes I can’t go to sleep because of too much enthusiasm. But can be also equally frustrating. You don’t what to know how many companies I changed because I would rather jump from the window than doing something that I no longer consider challenging.

My workshop doesn’t have a clear purpose. I have only a general idea of that tools and machines I would like to have to support my ever changing activities. For around three decades I was interested in analog electronics and programming. But slowly it stopped be so exciting as before. About two years ago I discovered machining. And since everything is new to me I found it a very interesting domain to dive into.

I don’t think they cut wood with the saw because it was no longer capable to cut metal. The blade and motor are dead, ok. But beside that I didn’t saw nothing suspicious. All adjustments are working fine. Worst case there could be some problems in the bottom box. But since I will use a VFD nothing from there is essential.

7 October 2024 at 14:04 #757805SillyOldDuffer

Moderator@sillyolddufferWell, my version of Model Engineering has little to do with the textbook definition of it. I wonder for how long I’ll be tolerated here. Sometimes I’m thinking on trying to build a small engine, maybe this one. And to connect it to a small generator to power some of my vacuum tube radios.

Don’t worry about fitting in! Model Engineering is a broad church.

My version of Model Engineering is somewhat like yours. I have built a few model engines, but mainly to learn technique, not because I’m into models. My interests are experimental, and apart from machine tools being intriguing in themselves, being able to manufacture custom parts is handy. For the same reason I’ve put effort into CAD and 3D-printing, also absorbing subjects in their own right. I got to mechanical engineering late via electronics, amateur radio, astronomy, and photography. Wanted to go into science, chemistry, but judged my maths to be inadequate in a world where chemistry had become physics! My profession was computing, an engineering discipline, where my employer had many odd applications! Also interested in industrial history, even the boring bits like economics.

All those different activities in a short period are cause by my very low tolerance to boredom. I must be always stimulated by new ideas, activities or at least good book. This is a great source of satisfaction. Sometimes I can’t go to sleep because of too much enthusiasm. But can be also equally frustrating. You don’t what to know how many companies I changed because I would rather jump from the window than doing something that I no longer consider challenging.

There we differ. I have quite a lot of patience, but the cost is being rather slow-witted.

My workshop doesn’t have a clear purpose. I have only a general idea of that tools and machines I would like to have to support my ever changing activities.

Fine by me!

I don’t think they cut wood with the saw because it was no longer capable to cut metal. The blade and motor are dead, ok. But beside that I didn’t saw nothing suspicious. All adjustments are working fine. Worst case there could be some problems in the bottom box. But since I will use a VFD nothing from there is essential.

You may well be right. I’m suspicious because bandsaws become less accurate as the bearings and other components wear, causing the blade to wander. Your machine when new would have cut accurate and straight to a high-standard. Perhaps it still does, maybe not. Saws no longer good enough to cut metal accurately perform well enough for woodwork, making it tempting to repurpose rather than pay for an expensive rebuild. A saw of that quality being used to cut wood is a worry.

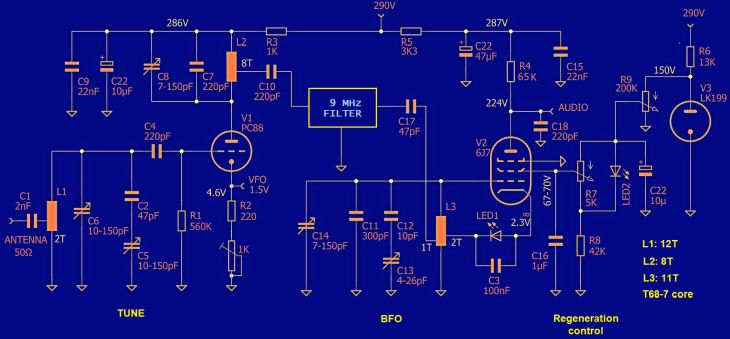

I’m fascinated by your 14MHz valve receiver.

I guess the circuit extreme left is a pre-amp, and that on the far right is the audio amp. The glowing bottle in the middle is a voltage regulator. Much less confident of the rest, or even the operating principle. Is it a superhet with a product detector or what? The audio sounds nice and crisp.

I’ve given up radio operating because my home was chosen to be near good schools for the kids and for a reasonable commute to work for self and wife. Disastrous radio location: it’s in a village with overhead power lines, and the shape of the garden makes it impossible to put up a decent antenna. People hear me, but they’re swamped by noise. Very sad!

Dave

7 October 2024 at 22:00 #757905 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234I guess the circuit extreme left is a pre-amp, and that on the far right is the audio amp. The glowing bottle in the middle is a voltage regulator. Much less confident of the rest, or even the operating principle. Is it a superhet with a product detector or what? The audio sounds nice and crisp.

Yes, it is a superhet but with a regenerative detector. I like simplicity. Actually the RF part has only two tubes. The mixer and the detector. Here is the story how I designed it (google translated)

I’ve given up radio operating because my home was chosen to be near good schools for the kids and for a reasonable commute to work for self and wife. Disastrous radio location: it’s in a village with overhead power lines, and the shape of the garden makes it impossible to put up a decent antenna. People hear me, but they’re swamped by noise. Very sad!

Dave

Well, it depends how you look at it. It can be just another challenge. My most successful radio activity was when I lived in Munich where the antenna was just a 15m wire hanged from the balcony to a tree. RF ground was the building metal rebar structure. I talked with people from Scotland to Crete on 3.6MHz. That is where the random wire (together with the apartment building) happened to have the best impedance matching 🙂 For reception is not unusual to use a separate antenna for better noise performance. Could be an array to decrease noise because of directivity, or a magnetic loop, or an RF noise canceling adapter.

8 October 2024 at 08:51 #757950not done it yet

Participant@notdoneityetDave, interesting read from both of you.

My interest has always been to the scale of 12” to the foot.

I disagree with the following in this example:

I’m suspicious because bandsaws become less accurate as the bearings and other components wear, causing the blade to wander.

It’s a vertical only, not the typical horizontal carp from China. The blade is supported, over its cutting setting, on both sides and one edge – not like the average wobbly arrangement in many amateur workshops. This one, if the blade stays on, is limited to vertical cuts so much simpler in that respect but less versatile for the average model engineer with limited space/funds but needing versatility.

8 October 2024 at 10:24 #757967SillyOldDuffer

Moderator@sillyoldduffer… Is it a superhet with a product detector or what? The audio sounds nice and crisp.

Yes, it is a superhet but with a regenerative detector. I like simplicity. Actually the RF part has only two tubes. The mixer and the detector. Here is the story how I designed it (google translated)

I’ve given up radio operating because my home was chosen to be near good schools for the kids and for a reasonable commute to work for self and wife. Disastrous radio location: it’s in a village with overhead power lines, and the shape of the garden makes it impossible to put up a decent antenna. People hear me, but they’re swamped by noise. Very sad!

Dave

Well, it depends how you look at it. It can be just another challenge. …

Every 5 years or I have a burst of enthusiasm and have another go! It’s a receive problem. Last time I installed a LZ1AQ loop in the loft. It’s a double loop that can be configured remotely in 3 combinations, one of which is far less noisy than the others, but still not good enough. I get out OK with less than 10W to the transmit antenna and a few milliwatts of WSPR is reported too. Unfortunately any replies are well down in the noise and difficult to make out. On CW I report 299 QRM rather than 599! And that’s a genuine strength 9, not the usual ham fiction.

A big part of my problem is living on a street corner surrounded by pole strung power and telephone cables. Doesn’t help that the village is in a kind of bowl, which appears to block HF rather well. My receivers pick up more good signals on a wire thrown out the window at my mum’s house than they do on a better engineered antenna here.

The main issue though is radiated noise on the power lines. I’ve explored the village with a portable receiver hoping to find an obvious single source with no luck. It appears that everyone has a house full of cheap switch-mode power supplies and other noisy gadgets that couple efficiently into the power system. Filtering the mains inside my home makes no difference – the noise is on the antenna. Data modes are possible except I don’t enjoy them!

Thanks for explaining your receiver. I read the article with considerable interest. Despite claiming simplicity, that’s a novel design with several tricky challenges, and you made it work! I should have twigged it was a regen from the way you twiddled the knobs in the video! Love it. Apart from communications radio generally, I have a soft spot for valves, aka tubes, and now ‘lamps’. We are not alone – quite a few forum members are also radio amateurs or do radio control.

Dave

8 October 2024 at 11:29 #757976SillyOldDuffer

Moderator@sillyolddufferDave, interesting read from both of you.

…

I disagree with the following in this example:I’m suspicious because bandsaws become less accurate as the bearings and other components wear, causing the blade to wander.

It’s a vertical only, not the typical horizontal carp from China. The blade is supported, over its cutting setting, on both sides and one edge – not like the average wobbly arrangement in many amateur workshops. This one, if the blade stays on, is limited to vertical cuts so much simpler in that respect but less versatile for the average model engineer with limited space/funds but needing versatility.

Yeah, you may well be right, which is why I used the word ‘suspicious’, rather than anything stronger.

My suspicion is based on the reason the maker put so much quality into this saw. The way it’s built suggests it’s intended for protracted hard work requiring both robustness and accuracy. And accuracy to a high-specification too. Accuracy declines as machines wear, so it’s possible that this 70 year old saw, is now way off. May not matter: even though my Chinese hobby saw is imprecise, and the output may require some fettling, it still saves me lots of time and effort. The same saw would annoy the hell out of anyone who needed to do loads of fast accurate sawing.

We can only guess at the how good or bad Sonic’s saw is. He needs to try it. The proof of the pudding is in the eating!

As background, I’m always nervous when Model Engineers buy ex-industrial kit that they might be assuming a reputable brand-name and build quality somehow magically guarantees the machine will be wonderful. Maybe, maybe not; unfortunately condition depends on the machine’s history.

If a well-made machine needs repair, then replacing a set of high-end bearings alone can easily exceed the second-hand cost of the whole machine. Got an interesting book dating back to when manual lathes did most of the work in factories. In a 3-shift factory, circa 1925, a well-made Herbert lathe was expected to last 3 to 5 years, after which they were scrapped, worn out, ‘Beyond Economic Repair’. It’s run time and loadings that matter, not the chronological age. So before buying in hope of high-specification and reliability, check the condition carefully. Unless of course your hobby is reconditioning old machines!

After about 1990 hobbyists did exceptionally well out due to industry and education dumping large numbers of manual machines long before they wore out. Industry either outsourced abroad, or went CNC, creating a shower of genuine bargains. I think from looking at recent prices that the happy time is ending. I guess after 30 years the market is no longer flooded with good unwanted industrial kit, and demand is starting to exceed supply. As this can only get worse, anyone who wants to buy second-hand industrial Western made should act sooner rather than later.

Dave

8 October 2024 at 12:04 #757979not done it yet

Participant@notdoneityetI’m always nervous when Model Engineers buy ex-industrial kit

So would I be suspicious – if it were me buying. Buying blind would mean a ridiculously low price – not so much over scrap value if it could not be shown to work/run at the point of collection (and payment).

But in this case the likely (final) failure was due to the motor windings – which may have been caused by operational over-load, overload due to another machine bearing failure, motor bearing failure, overheating due to poor/blocked cooling, insulation break-down/ingested foreign body – or maybe something else?

The motor may even still run – but very rough due to phase imbalance.

Good (for me) if it were only needing a different motor (if space is not a problem) and a general tidy-up. Not a lot lost if a total loss, with only scrap value – which I doubt is the case here. It’s not as though it is a precision machine, like a lathe or mill.

8 October 2024 at 20:38 #758047 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234This 1951 machine has plastic gears!!!

Today I had one hour free and I was planning to do some progress on the saw. What could be simpler than removing that gear from the motor.

While I was spinning happily the wrench I heard a cracking noise. Just like a piece of wood that breaks. Strange, nothing should sound like this. But then I had a better look at the gear.

Is is made from some kind of sponge. It is very light weight. I didn’t realized this. I used only gloves, and also it was very dirty. And what is worse, the gear was hold in place by these two screws that I missed completely!

Now I’m thinking to order a new metal gear. Or better to wait until I have a better look inside the bottom part of the saw. I have many gears from a junk yard visit and maybe I can do some interesting modifications. Anyway, this was a big surprise, I did not expected this!

Next I disassembled the motor. Just out of curiosity. I think is clear why it died. The dust covered completely the ventilation openings. This is the front cover:

Air is suppose to circulate between the windings and the motor case. But half of that space was blocked by dust. Modern sealed induction motors are much better in this regard.

8 October 2024 at 21:05 #758057

8 October 2024 at 21:05 #758057bernard towers

Participant@bernardtowers37738More likely to be tufnol

9 October 2024 at 12:18 #758184not done it yet

Participant@notdoneityetIt might look to me to be a case of getting a suitable file to 3-D print a fresh set of gears?

That pic ‘appears’ to show the teeth being fairly worn (a few mm behind the end shape, which appears to never have been meshed).

You have not yet tested the motor – only measured resistance to earth? That low resistance could yet be caused by something foreign between winding and frame.

As per Bernard, I expect the gear is Tufnol. Acetal may well be a suitable alternative?

Is it only the motor gear that is worn , or the others, too? Often Tufnol was used against metal gears simply to quieten the gear train. Also, metal to metal gears require better lubrication.

Do consider that those gears will be much more heavily loaded if the variable speed device is “bypassed”. That motor would be working at its designed speed, whenever in use – not the same if using a VFD for speed attenuation.

There appears to be more to this machine design than you have considered?

12 October 2024 at 22:38 #759044 Sonic EscapeParticipant@sonicescape38234

Sonic EscapeParticipant@sonicescape38234You have not yet tested the motor – only measured resistance to earth? That low resistance could yet be caused by something foreign between winding and frame.

As per Bernard, I expect the gear is Tufnol. Acetal may well be a suitable alternative?

Is it only the motor gear that is worn , or the others, too? Often Tufnol was used against metal gears simply to quieten the gear train. Also, metal to metal gears require better lubrication.

I measured the resistance of each phase winding relative to the common point. The motor is wired in Y configuration. Two windings are 9Ω, plausible. But the third is >40kΩ. Unstable reading. And this is not caused by test leads contact issues. That was the only Tufnol gear. The metal ones are fine.

I want to remove the bottom back cover. All gears, speed adjusting mechanism, brake and clutch are attached to it. So it would be much easier to work there. But first I have to remove this arbor. And I don’t know how.

That is connected outside to the speed adjustment handwheel. As you can see the arbor has an increase diameter outside. That means I have to somehow pull out the handwheel together with the arbor.

There is a slotted round nut that I suppose I have to remove it.

But is jammed completely. I used a C type wrench to block the nut and I tried to turn the handwheel but no result.

I even used a chain wrench around the base of the handwheel and I press it with my foot but still nothing. What do you think about this? Am I missing something? I have no idea what else to try.

Together with a friend we removed the top wheel. It took more that half an hour since we had to remove screws in the narrow space behind the wheel.

This is the disassembled band guide. It is quite heavy.

I suppose this is the key part responsible to left/right blade stability. Looks like it is made from some hardened steel. That slot should match the blade thickness?

The next one is an interesting part. It is located above the previous blade guide.

That guide on the left is made from rubber. And the middle part has an oil reservoir inside. I guess the bottom of the rubber guide is porous or something and allow the oil to lubricate the blade. The rubber part doesn’t look too bad after 70 years. Unless somebody made a new one at some point.

12 October 2024 at 22:53 #759045 Grindstone CowboyParticipant@grindstonecowboy

Grindstone CowboyParticipant@grindstonecowboyDifficult to see, but that’s not a left-hand thread, is it?

Rob

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › General Questions › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

My vise isn’t at 90 degrees

Started by:

moonman in: Beginners questions

- 3

- 3

-

19 July 2025 at 22:58

David George 1

David George 1

-

More BBC Masterchef woes…

Started by:

Nigel Bennett

in: The Tea Room

Nigel Bennett

in: The Tea Room

- 6

- 6

-

19 July 2025 at 22:55

Nigel Graham 2

-

Hopeless…

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 1

- 1

-

19 July 2025 at 22:51

Nigel Graham 2

-

Boley 6LZ, new to me

Started by:

Wade Beatty in: Manual machine tools

- 4

- 5

-

19 July 2025 at 22:47

Wade Beatty

-

Polishing compounds for stainless steel (mild abrasives))

Started by:

Simon Williams 3 in: Beginners questions

- 3

- 3

-

19 July 2025 at 22:30

noel shelley

-

What Did You Do Today 2025

1

2

…

7

8

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 196

-

19 July 2025 at 21:50

bernard towers

-

opposed twin engine calculations

Started by:

bricky in: I/C Engines

- 10

- 16

-

19 July 2025 at 21:50

bricky

-

Diving in to ATC?

Started by:

Steve355 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 4

- 5

-

19 July 2025 at 21:12

Bazyle

Bazyle

-

Paint stripper does not do what it says on the tin

Started by:

Greensands in: Hints And Tips for model engineers

- 5

- 11

-

19 July 2025 at 21:08

Greensands

-

Boxford paint colour

Started by:

Pete.

in: Workshop Tools and Tooling

Pete.

in: Workshop Tools and Tooling

- 5

- 9

-

19 July 2025 at 19:05

Michael Gilligan

Michael Gilligan

-

Taylor Hobson cutter grinder modificaton

1

2

Started by:

David George 1

in: Workshop Tools and Tooling

David George 1

in: Workshop Tools and Tooling

- 9

- 36

-

19 July 2025 at 18:41

Michael Gilligan

Michael Gilligan

-

Bad design, or am I missing something?

Started by:

half whit in: Beginners questions

- 3

- 3

-

19 July 2025 at 17:19

Michael Gilligan

Michael Gilligan

-

Even the Dealer Didn’t Know!

Started by:

Chris Crew in: The Tea Room

- 15

- 19

-

19 July 2025 at 17:04

Bo’sun

-

Easiest/cheapest source of R8 socket

Started by:

Beardy Mike in: Workshop Tools and Tooling

- 13

- 24

-

19 July 2025 at 15:20

JasonB

JasonB

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 23

- 47

-

19 July 2025 at 12:28

Howard Lewis

-

New member

Started by:

Dave Lewis

in: Introduce Yourself – New members start here!

Dave Lewis

in: Introduce Yourself – New members start here!

- 3

- 3

-

19 July 2025 at 12:01

Howard Lewis

-

Boiler Design – issue 4765

1

2

…

8

9

Started by:

Charles Lamont in: Model Engineer & Workshop

- 27

- 213

-

19 July 2025 at 11:13

duncan webster 1

-

Please direct me to where I can find an engineer to do some bespoke work

Started by:

srb1 in: Beginners questions

- 5

- 9

-

19 July 2025 at 10:44

duncan webster 1

-

How many spokes do I really need?

Started by:

Fulmen

in: Related Hobbies including Vehicle Restoration

Fulmen

in: Related Hobbies including Vehicle Restoration

- 8

- 21

-

19 July 2025 at 07:30

Fulmen

Fulmen

-

Model Engine running just off a naked flame

Started by:

Blue Heeler

in: Stationary engines

Blue Heeler

in: Stationary engines

- 3

- 5

-

19 July 2025 at 04:57

Blue Heeler

Blue Heeler

-

Herbert B drill information?

Started by:

Andrew Tinsley in: Workshop Tools and Tooling

- 4

- 11

-

18 July 2025 at 20:23

Andrew Tinsley

-

Which lubricator do I need

Started by:

Michael Callaghan in: Locomotives

- 3

- 4

-

18 July 2025 at 19:53

duncan webster 1

-

Backplate studs

Started by:

Dalboy in: General Questions

- 5

- 7

-

18 July 2025 at 19:46

Dalboy

-

William Hazeldine … Proving Machine

Started by:

Michael Gilligan

in: Materials

Michael Gilligan

in: Materials

- 5

- 8

-

18 July 2025 at 18:47

Michael Gilligan

Michael Gilligan

-

Measuring a double Vee lathe bed Vee position

Started by:

Kim Garnett in: General Questions

- 11

- 21

-

18 July 2025 at 15:26

Pete Rimmer

-

My vise isn’t at 90 degrees

-

Latest Issue

Newsletter Sign-up

Latest Replies