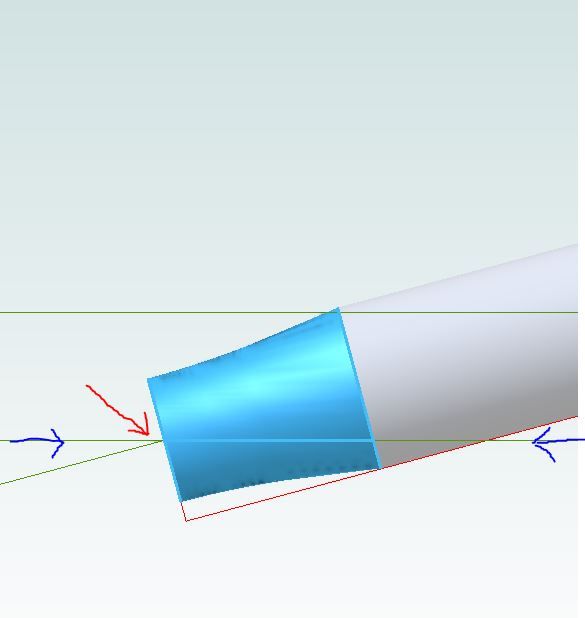

Theoretical Taper due to tailstock height misalignment.

Theoretical Taper due to tailstock height misalignment.

- This topic has 99 replies, 28 voices, and was last updated 8 January 2023 at 09:11 by

Martin Connelly.

Martin Connelly.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- road registration and traction trailer.

- Bridgeport ways and wear

- Motorised Adept No. 2 Shaper

- Starrett and other tool manufacturer wood boxes

- What Did You Do Today 2025

- Speed camera

- Pragotron Slave Clock

- Twin Engineering’s heavy mill/drill quill removal

- Herbert B drill – a question and a curiosity…

- New member