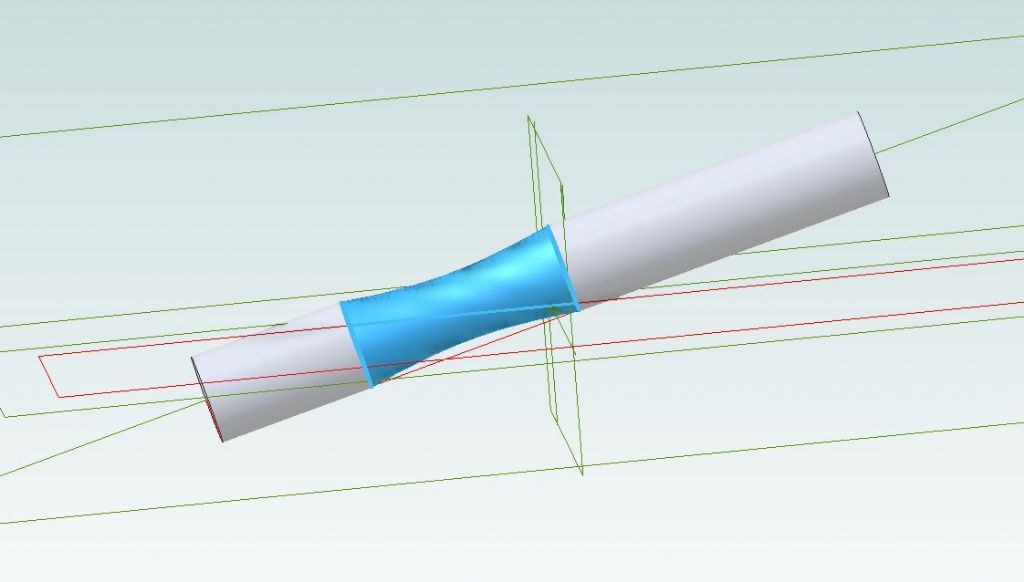

If the material is being turned between centres, being large at the Tailstock end, suggests to me that the tailstock is not on the same axis as the Headstock, , as first point of investigation.

Once is coaxial with the Headstock, then the Tailstock being high, and its lesser effect can be investigated.

My suspicion is that a vertical misalignment will have a far lesser effect than a horizontal one, since horizontal movement directly varies the distance between work and the cutting tool.

And the larger the diameter of the workpiece, the smaller will be the effect of any vertical misalignment.

A vertical misalignment of 0.001" on a 1" diameter bar would represent an angle of 0.11459 degrees

On a 1" diameter, this would increase the distance from tool to metal from 0.005" to 0.500001" A difference of 1/100,000 of an inch, (3.9370079 x 10 ^ – 8 mm . Approximately 4/100 of a micron by my calculation ).

If you hold the mic or calliper long enough to measure the discrepancy, the temperature effect will produce an error of that magnitude!

Howard

Edited By Howard Lewis on 07/06/2021 15:16:05

Martin Connelly.

Martin Connelly.