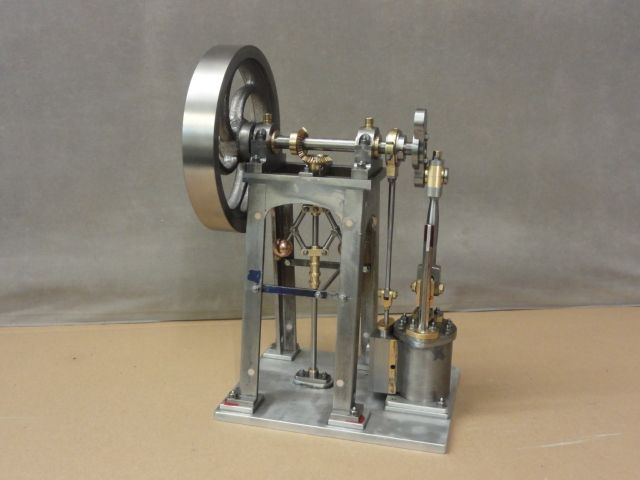

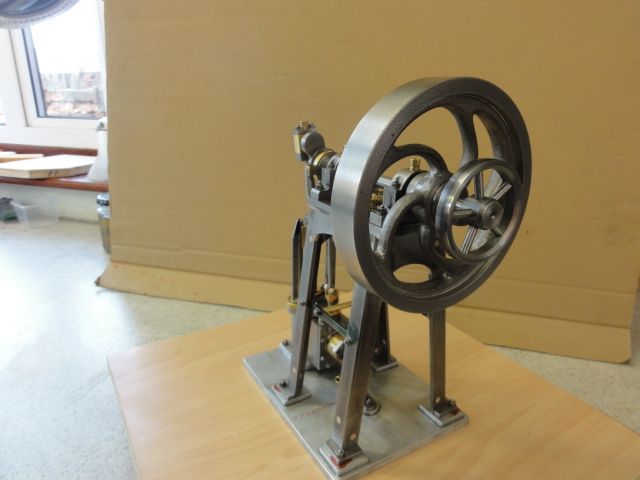

Nearly finished restoration of my BNL no5 Arbor Press, while taking it apart the hand wheel broke, I tried pulling it off with a 3 leg puller but it snapped, it was spinning around freely on the Arbor but just would not come off, I ended up slitting it with a hacksaw then chain drilling it to remove a section so it would come off the Arbor.

After getting it off the problem became apparent, over time it must have been slipping and repeatedly got spun round causing the Arbor to mushroom out either side of the screw, and wear 2 grooves into the inside of the bore making it mechanically impossible to remove.

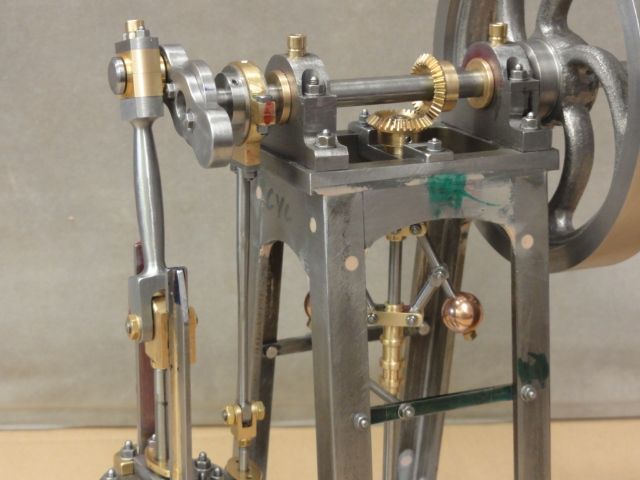

So decided to give mig bronze brazing a try as I've never done it, I was hoping this method would remove the need for pre heat and post heat, the repair below was done with no pre or post heat.

It's a bit tricky and definitely doesn't produce nice weld beads like Tig, but after a bit of fettling with the die grinder and a carbide burr, it's hard to notice where it was brazed anyway.

Edited By Pete. on 10/05/2022 17:44:17

JasonB.

JasonB.