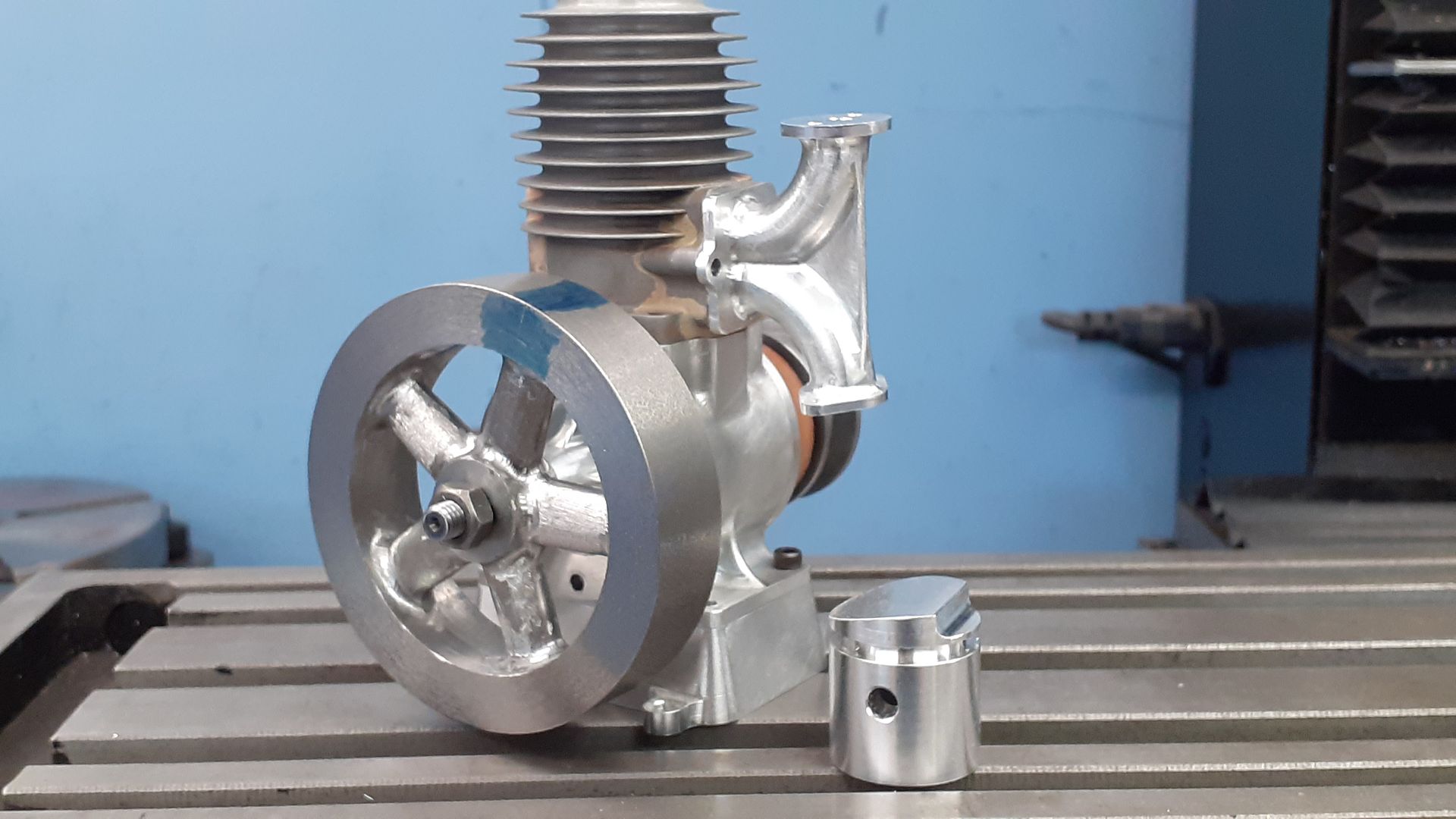

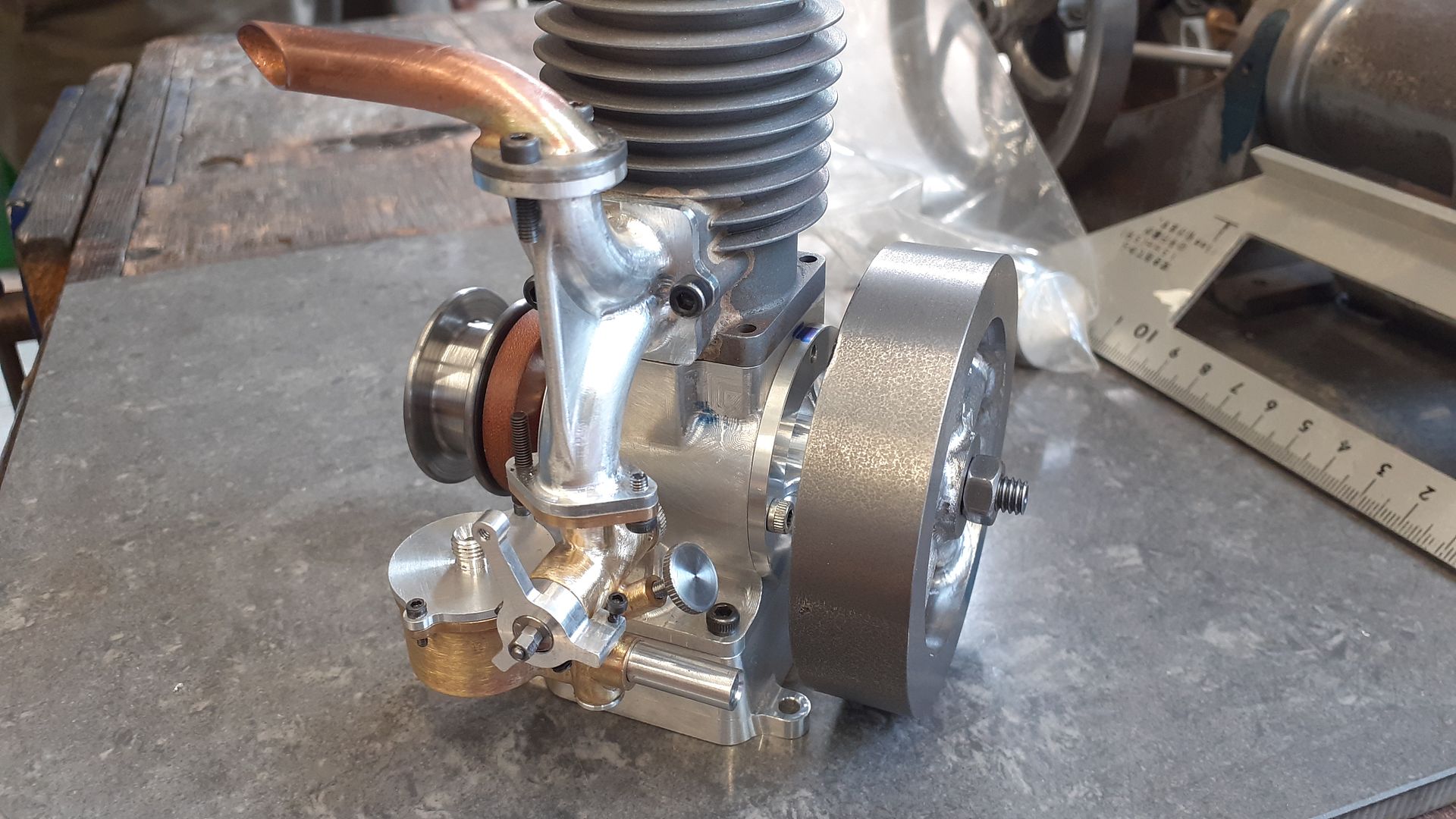

Making some more progress on my Norden engine. This is what I'm aiming at:

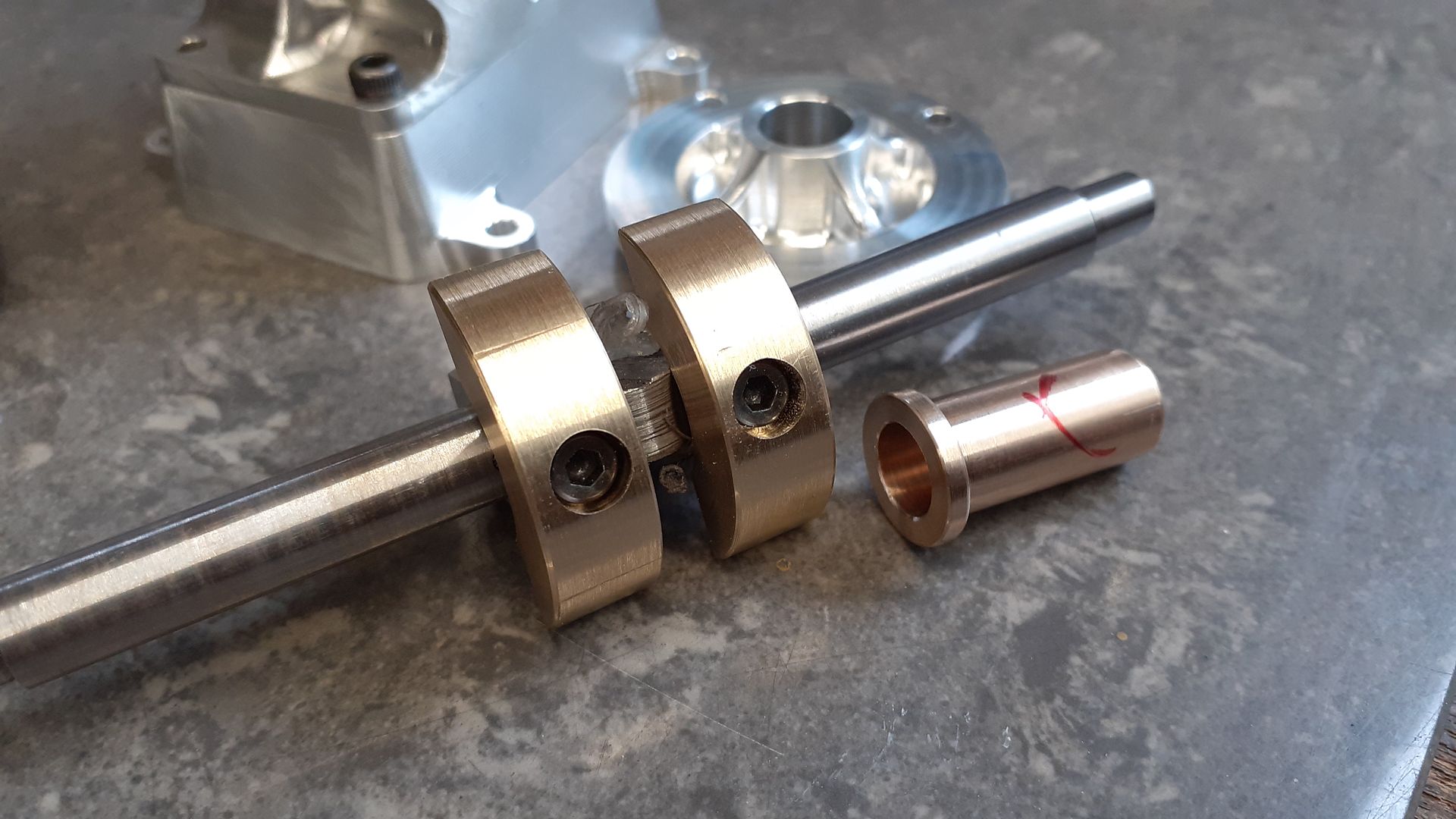

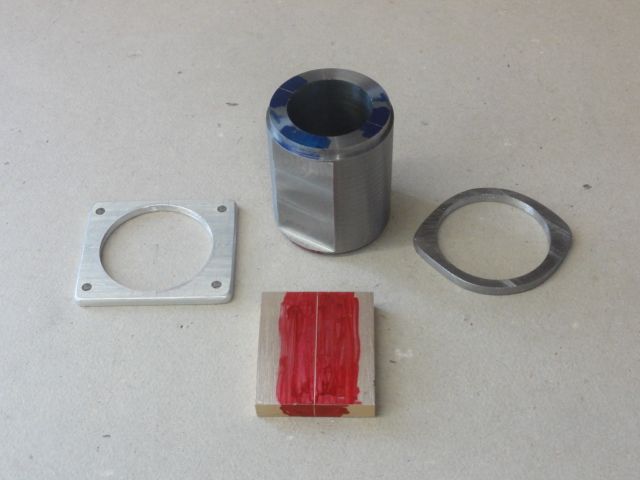

The frame and crankshaft bearings are done, latest fumblings involved making the cylinder. Here's the main components which replace the casting of the original model, the top and bottom flanges will be fixed with Loctite and the port face with JB Weld.

Here's the first scrapped attempt:

You may be able to make out the top of the broken off 8BA tap. I haven't broken a tap for ages but my mind wandered while I was doing the eighth one and that was that.

So I recovered the top flange, the rest went in he bin and I started again:

It's not easy to see why this also bounced off the wall but it moved in the vice when I was milling the brass port face and it ended up too thin and not square. So I started again again.

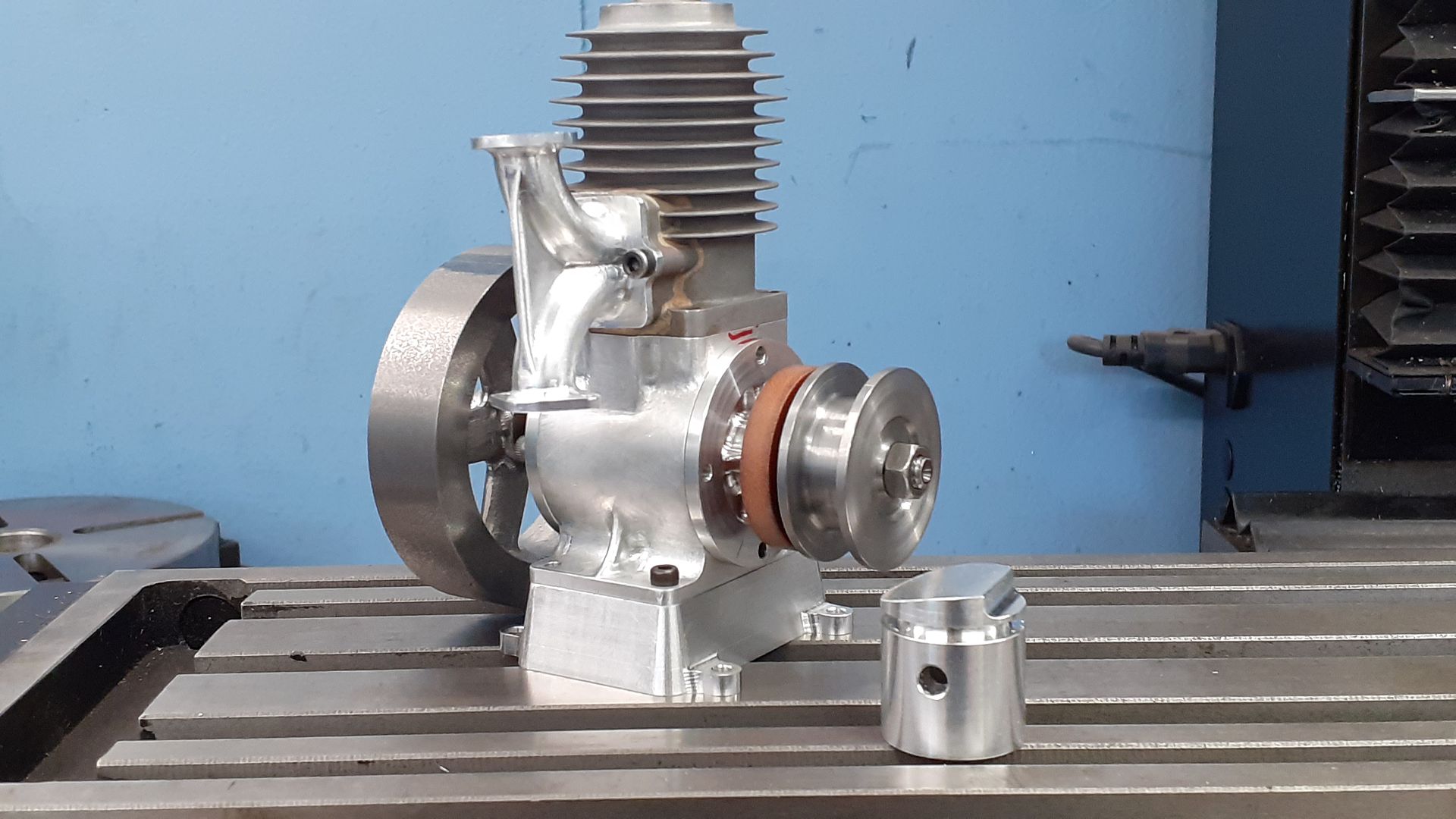

At last I successfully completed a cylinder and even got the cover done as well:

Steam chest next.

Jim

JasonB.

JasonB.