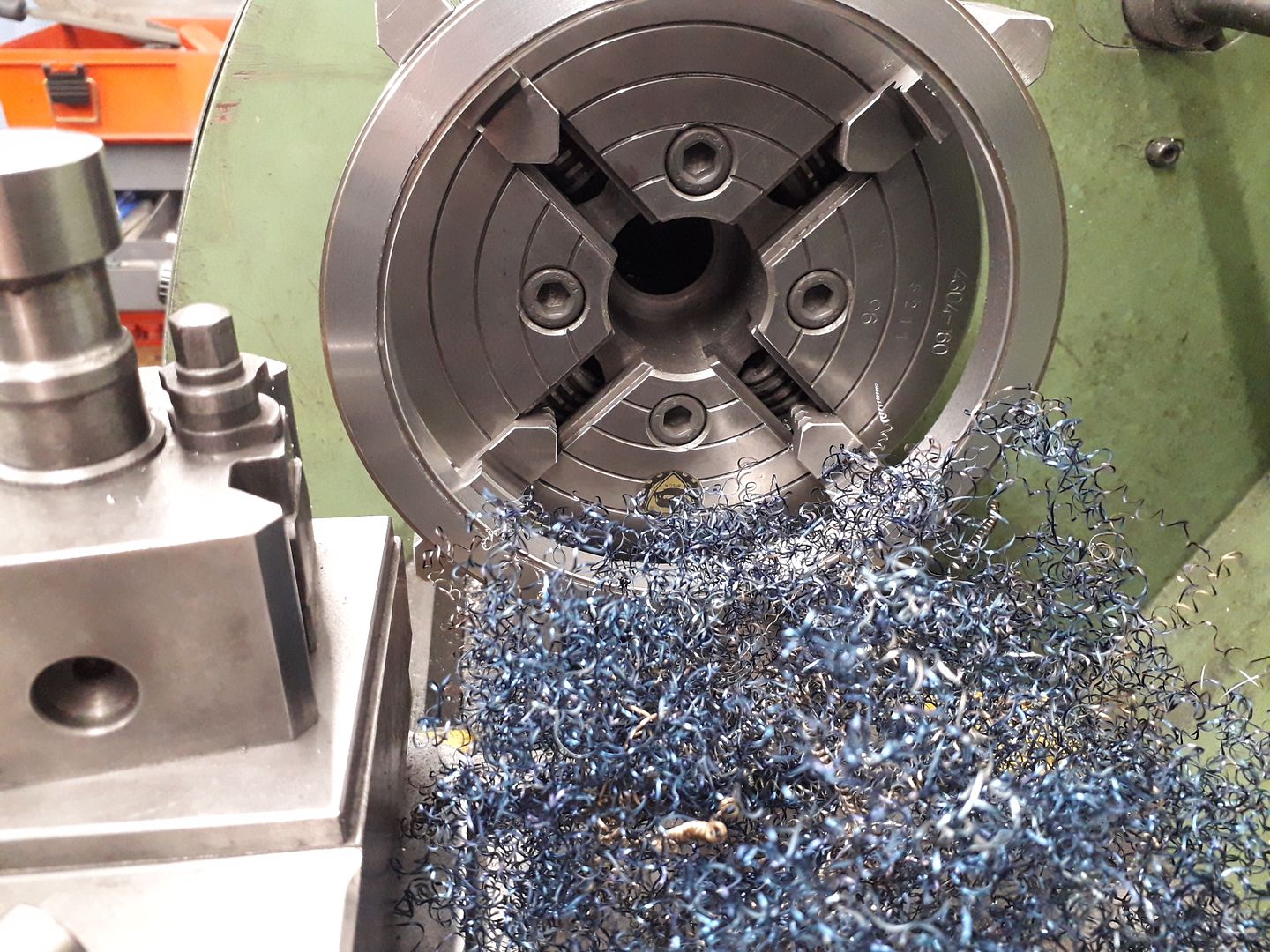

Thanks Ron, there is a slight amount of run out on the inside of the rim a sit cooled off slightlu oval by about 0.5mm so I trued up the outside in the lathe and had also left the hub undersize so that wa sbored out at the same setting which got it good enough and better than any casting.

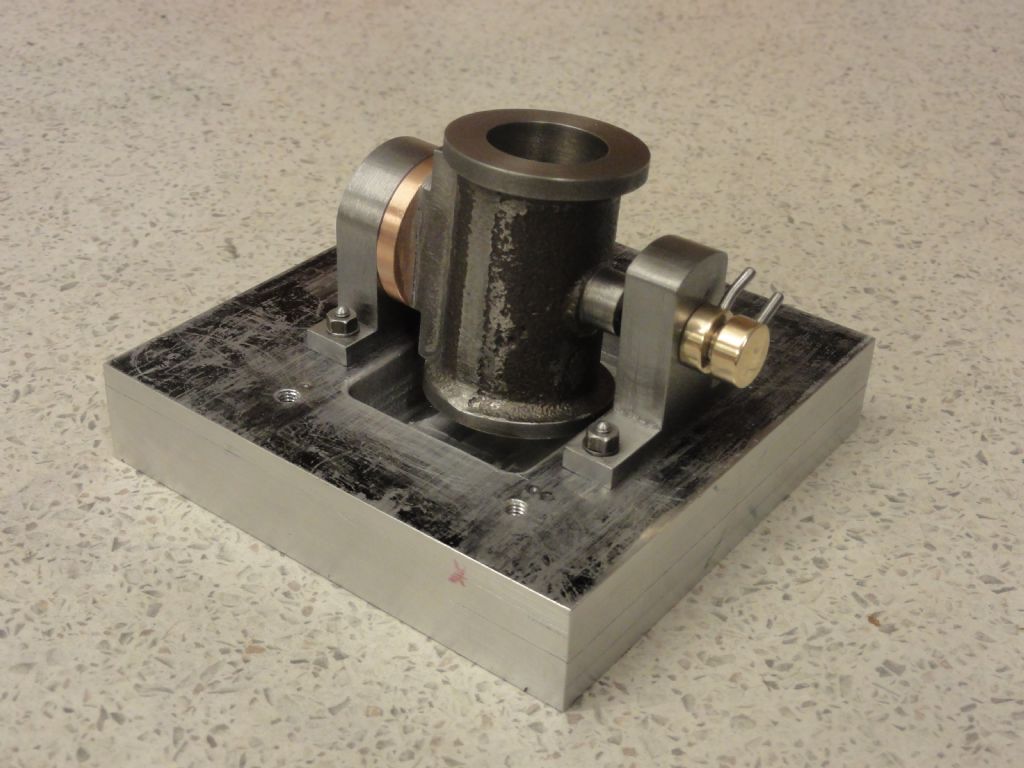

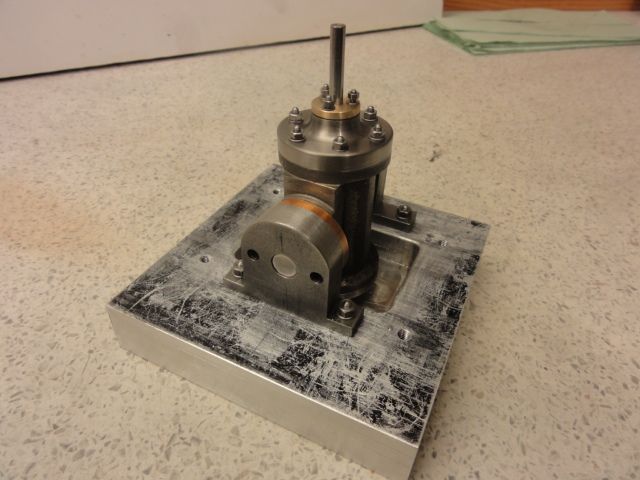

I had intended to give the Root and Van Dervoort vertical another try over the holidays and with the Type-B and Preston's Oscillator running thought I may be a on a bit of a roll so spent most of today on the R&V.

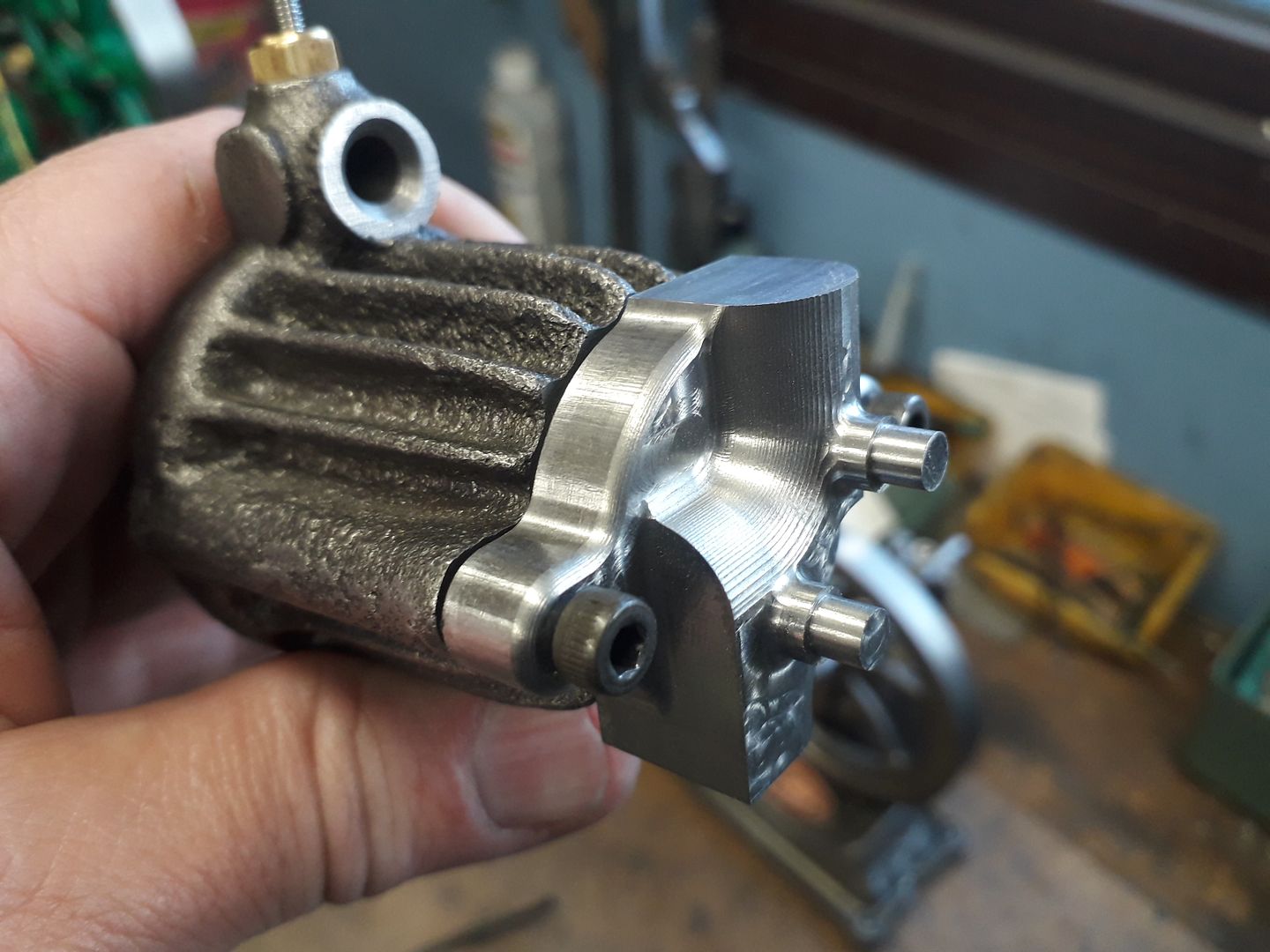

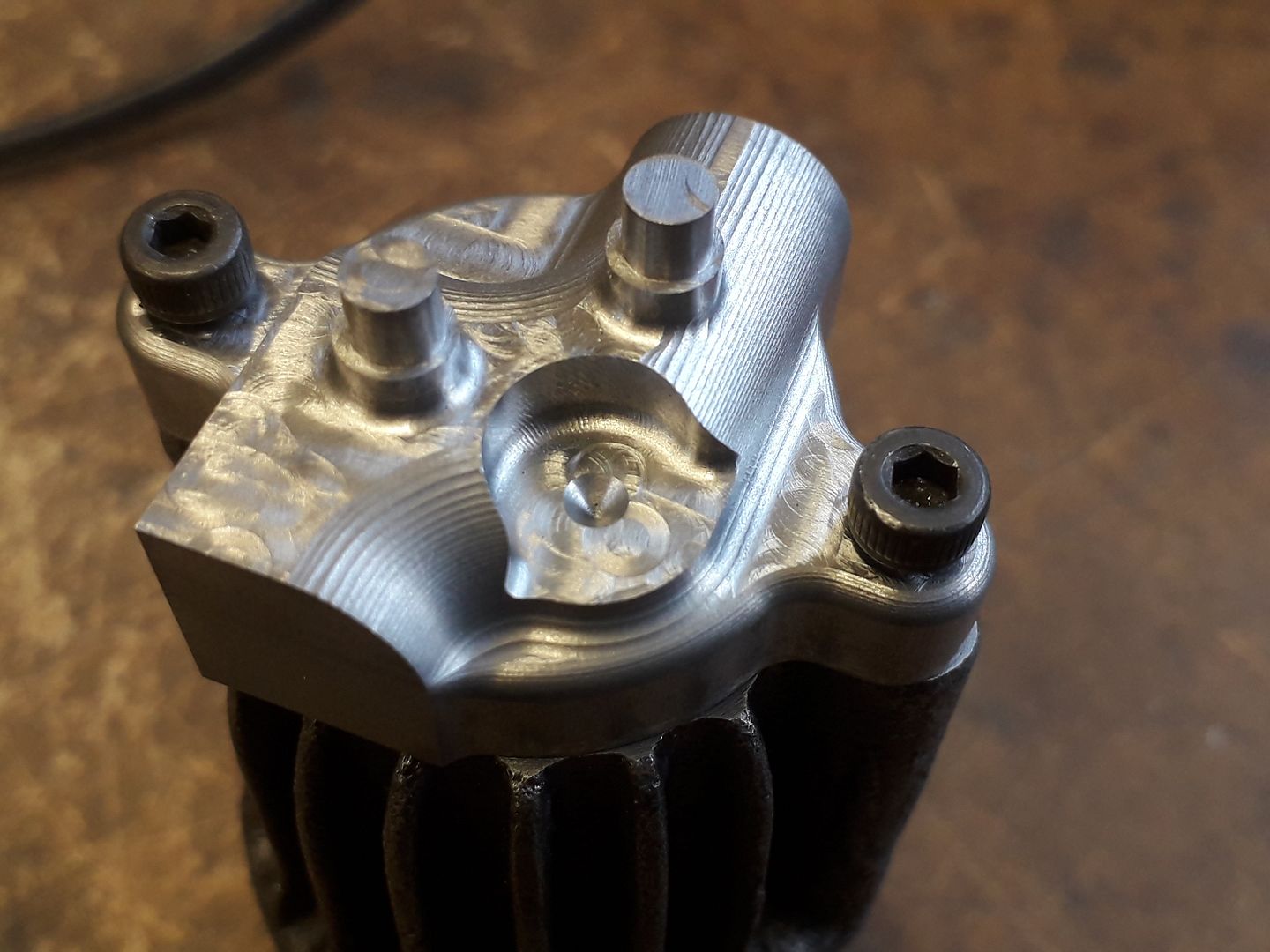

One of the issues was getting it to run strongly and for any length of time and I was having difficultly getting the timing right, as both the ignitor and exhaust valve are operated by the same rod it was impossible to get the ignitor to fire at TDC and the exhaust to open in the right position, if I set one then the other was well off. I decided to partly strip the engine and take the cam off for a closer look – not easy as the person who started the engine had pressed it onto an oversize shaft but I managed it in the end with a few levers and a hammer.

Turned out that the cam profile which moves the pushrod was not that close to what was on the drawing and the integral eccentric that drives the fuel pump was 20thou oversize so I made a new one and things have improved quite a bit. Still needs a couple of breaths before it fires in the hit position and therefore not making as much speed as it should preventing it latching out into miss mode for long but a lot better than it was. Need to put another pin hole in the push rod so the crocodile clip that in compressing the spring more can be removed. It ran for another 3-4mins after I stopped the video and then I turned it off as things were getting a bit warm with no water in the engine.

mechman48.