It's been a while and slow progress, but progress it is …..

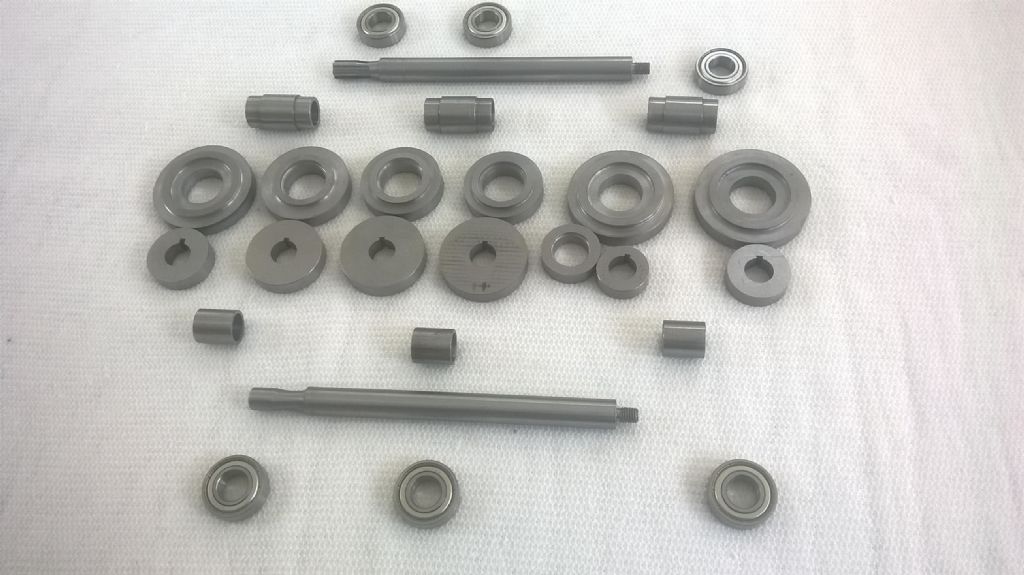

All the gear blanks for my 5-speed transaxle gearbox had been made, as have the input and ouput shafts, gear hubs and spacers. The output gears need the dogs machining and of course there is going to be a monumental gear cutting session coming up. I've been waiting until all the gear blanks were finished until setting up the rotary table. I had to alter the ratio of 3rd gear slightly as I can't obtain a 28 tooth pattern with my rotary table set up but it made little difference overall. Below are a couple of pictures from the album:

The gear internals so far, with some finishing still to do:

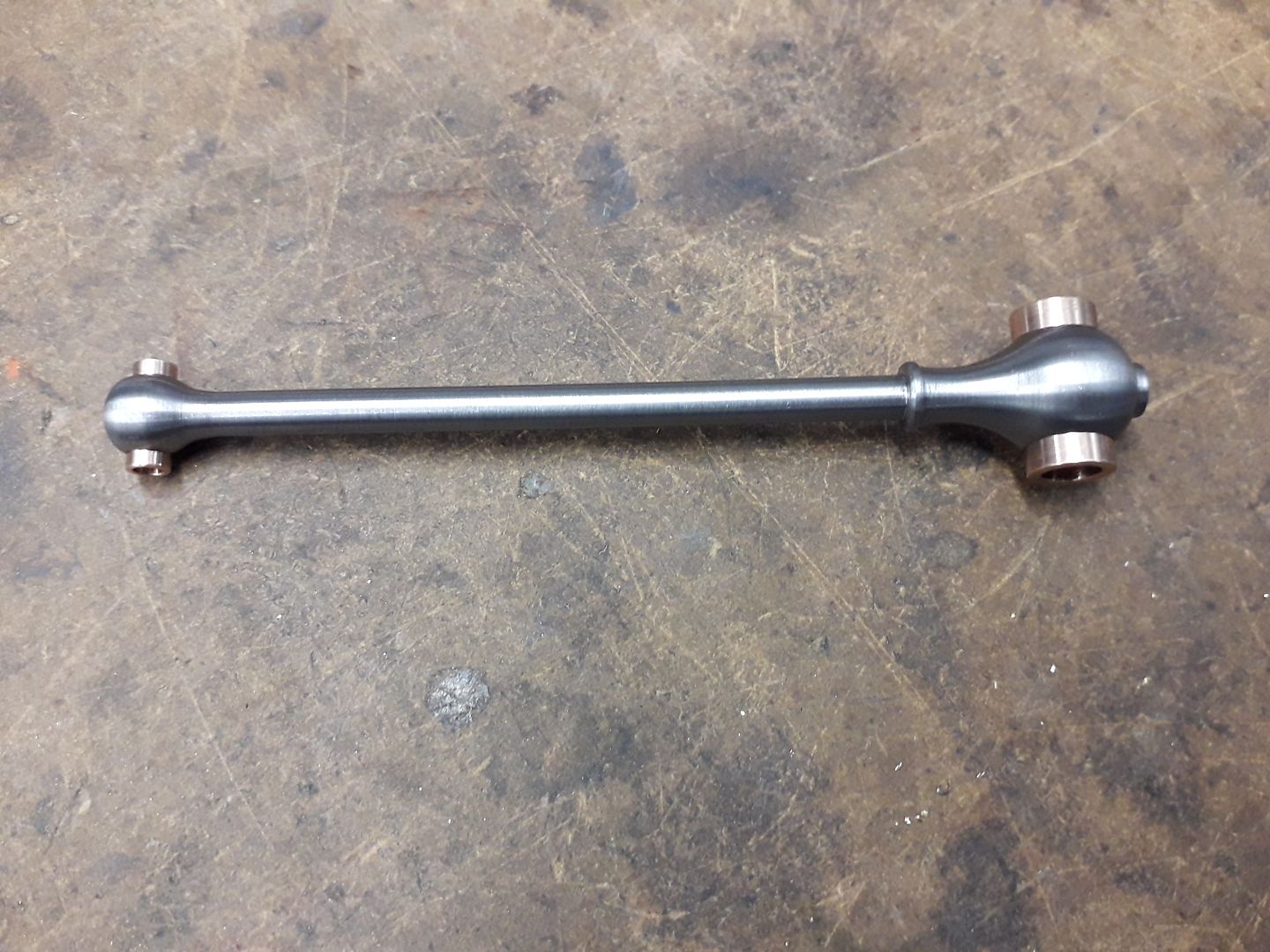

The same parts, loosely assembled. To give some idea of scale, the shafts are 201mm in length.

I am awaiting delivery of some 10mm thick perspex sheet to use as the casing faces for display of the finished workings. I'll post further pictures of progress later. Much later.

John

Ian McVickers.