Well, after posting in my Intro that I'm starting with a mill and will get to a lathe as time / finances / swmbo allows,

A very nice man, not far from me PM'd me and said I could have his old lathe if I wanted it.

Gawd, how I agonised about not actually biting his arm off for the offer and being polite . . . (i.e. not actually running him down in my rush to take up his kind offer)

So went to see the nice man, looked at lathe, went home, agonised about taking such a nice bit of kit.

Went back to see him, was plain about what I'd seen such items go for, he still seemed happy enough, didn't look like he'd lost his marbles, was in fact the very epitome of a nice helpful chap.

So, I bunged him a tab to distract him and piled all I could fit in the back of the motor and did a runner

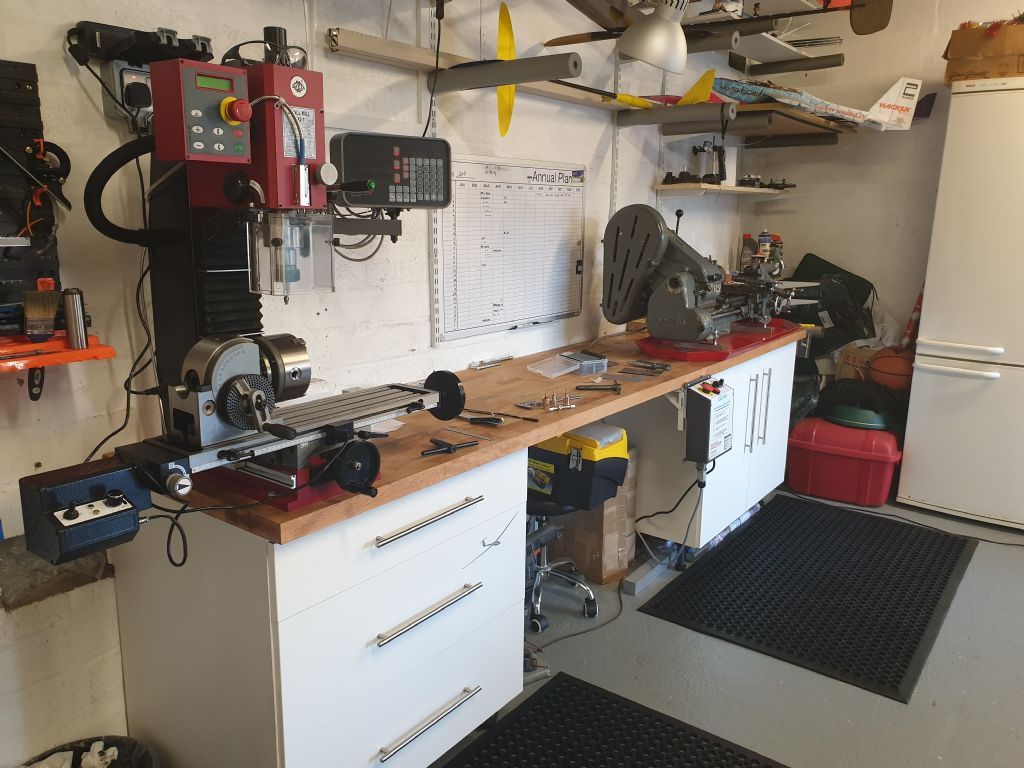

With new toys in garage just mocking me for my limited abilities (I've worked with hi tech machined tools all my working life in the oilfield and never knew how little I knew 'till I started to bodge bits of metal myself)

So, You choob is my friend, many and varied are the video's I've been watching, going from "DON'T EVER, EVER, EVER, leave a chuck key in"

To setting tool height, rpm, doc, feed rate . . .

And have made my first useful (I'd say "commissioned" but it was a wheeze dreamed up over whisky at a gliding club during a comp a couple of weeks ago) piece.

Which, much to my amazement, actually works.

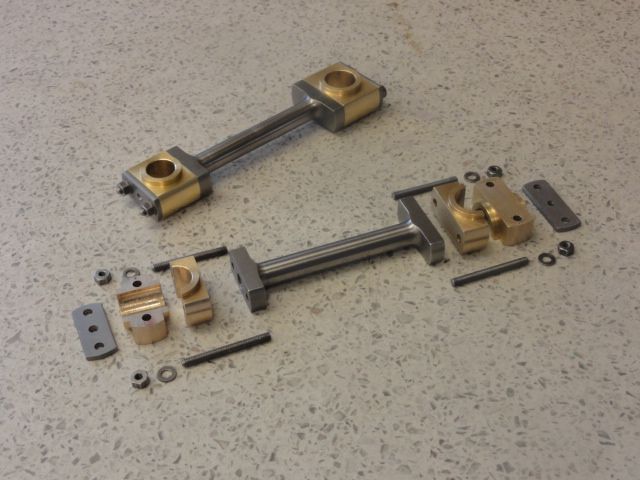

Knobs (the bronze thingies) they are used to pull a recessed nut out to allow wing extensions to engage on the glider.

So, in reality they are a bit of bronze spun down to look pretty and tapped M5 on the end, but hey, it's a start.

The regulation nut on a bit of oversize bar required additional tooling / motor / VFD / Yet more video's / More change gears from myford-stuff, and it too worked (work in this context being a bit grandiose)

Still on a very steep learning curve, but have yet to break any tools, all my injuries so far have been "band aid" sized, I'm learning how to get the swarf out of my socks before trudging round the house, all in all, so far so good.

The two most heavily used items in the garage so far seem to be the (selection of now) brushes and shop vacum . .

It's amazing where swarf can get to !

My confidence is rising to where I may yet have a go at something useful and complex . . slowly (with back up's hidden . . )

Ian McVickers.