Posted by JasonB on 18/01/2019 07:59:01:

Martin, I have spent a lot of time fiddling with the ignitor trip, it does not have the same adjustment methods as some or the horizontals that I have built so is a right pig to get working anywhere near right.

The pump does work when I have tried it with a cordless drill, may hook it up and run some water through it once the engine is running well though they don't get too hot and can be run for several minutes dry.

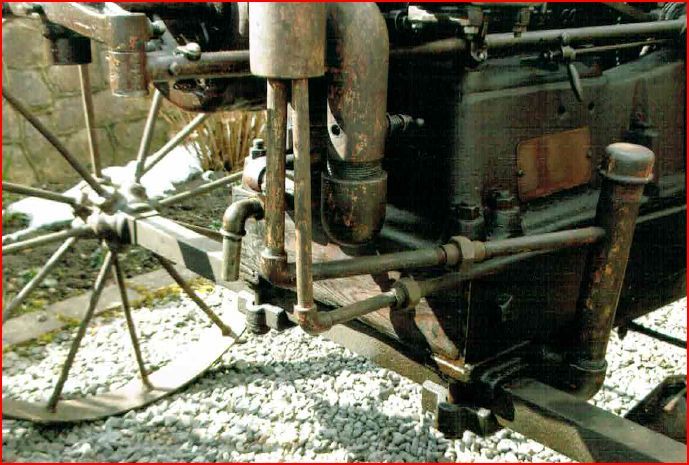

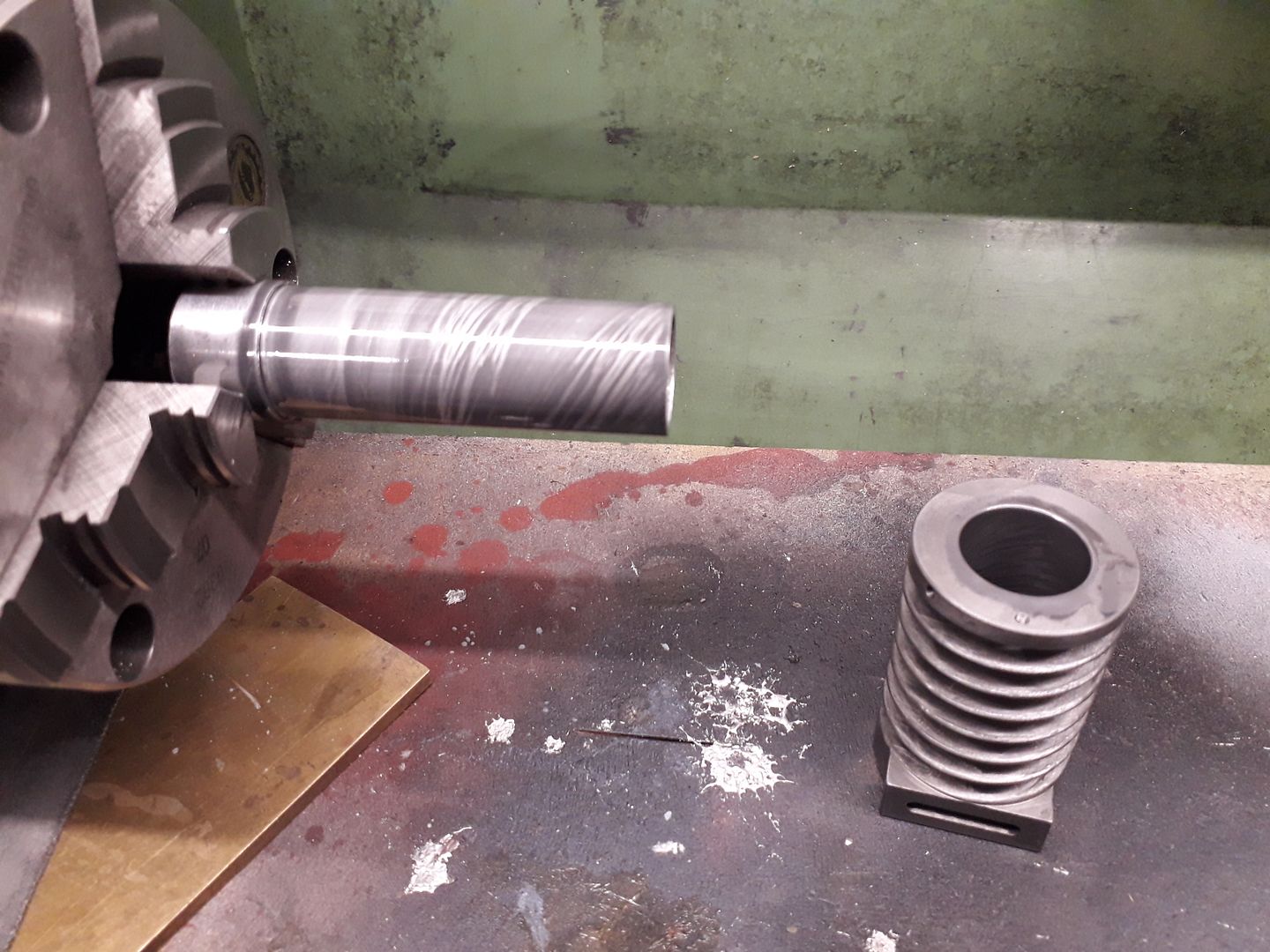

It is from a casting kit but the cart is scratch built. It came to me as part made with all the larger items having been done, there were some major issues such as a wonky crankshaft and the top of the crankcase was machined very out of true so the cylinder was leaning sideways

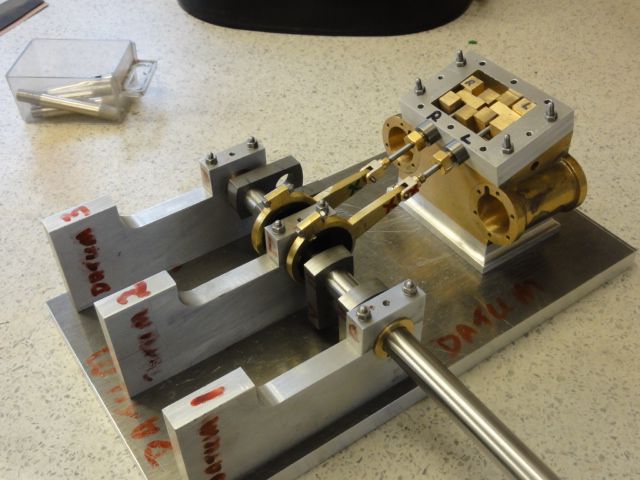

Ron, this is how I did the joints.

The engine would be classed as a Vertical Hit & Miss Engine. vertical as it stands upright rather than the more common layout with a horizontal cylinder.

The hit and miss bit refers to how the speed is controlled (not set working in that video) There is a pivoting weight on the inside of the flywheel that swings out as the engines speed increases, as it rotates round it pushes a lever that will latch the exhaust pushrod in the open position which means there will be no compression and the engine won't fire which is the miss part. As the speed drops the latch will release and close off the exhaust so the engine will then be able to draw in air/fuel as there will be a vacuum when the piston goes down – compressed – fire which is the hit part. When the engine is running under load it may not get up to a fast enough speed to miss so will fire on each stroke, if the load is taken off then it will start to miss. If you watch my video of it's stable mate you can see that the exhaust rocker arm only lifts clear of the valve about every 3rd or 4th cycle.

And before it was painted you can see me manually making it miss by holding the rocker down about half way through. The vertical should be running more like this.

Otherwise it is just a 4-stroke engine, the only slight difference is that the inlet valve does not have a mechanical opening such as push rod and rocker. It just has a weak spring which is just enough to hole the vale closed but on the intake stroke the vacuum in the cylinder will open the valve letting the air/fuel mix in.

As the carb is at the top of the engine this one also has a fuel pump down on the left hand side – the whole bottom casting is the fuel tank – which constantly pumps fuel to the carb with any excess flowing back down to the tank under gravity.

It does not use a spark plug but has what is known as an ignitor. Basically a set of moving contacts that are within the head. As the exhaust pushrod moves up it has a lever on the side which closes the contacts and allows electricity from the battery to flow around a circuit containing a low tension coil. As the rod goes up more it moves away from the ignitor and allows the contacts to open but the energy in the coil causes a spark to jump across the gap and this is what ignites the fuel. They are very tricky to make with lots of small parts and torsion springs to be wound.

As said by Martin cooling is buy water being pumped into the bottom of a water space around the cylinder then into voids in the head before overflowing down the wire mesh which cools the water before it gets pumped round again.

J

Thanks Jason,

That is fascinating and different too, I am really impressed with it I could sit and watch it run for ages. I can see what you mean about tricky to make with all those small parts and I can imagine it taking some time and effort to set up. I see from the link that it runs on gas, is that always the case or can they run on other fuel, I was assuming yours was running on petrol.

I have learnt something in using a slot drill to cut wood, again I would have assumed that wood cutting bits have to be used, thats good to know. Which wood did you make the box from Jason, is it oak.?

Very impressive, great stuff.

Ron

Ian McVickers.