It's here!

At last the new Mill has arrived. I'd planned to have a little travelogue of pictures, but the idea got lost in the excitement.

The most peculiar thing is that the arrival and installation went remarkably to plan. I don't expect that to happen to me!

It started a bit off key – on the way out to the Post Office, I saw a van at the end of the road and thought. 'hmmm'. And waited to see. It was my van – the chap had forgotten to call!

The fears I had of getting the crate down the slope to the back of the house were unfounded. Mr Van Man had a powered pallet truck with brakes and it went smooth as silk. I did, however have to wait for my husky young assistant to arrive to help (1/3rd my age and probably 3 times my strength! – also doing Aeronautical Engineering at Manchester, so skills as well as muscles!).

The first photo I took was this – the box and partly assembled hoist.

It was, of course dark by the time the delivery arrived.

The first step was to hoist it out of the pallet and put it on my custom built slideway into the shed.

Then what I knew would be the nasty part. Getting the engine hoist over the mill and into the shed. A bit of grunting and it was there (in 4 pieces, mind you – let's not get too ambitious).

The hoist it to bring it further into the shed (with my beautiful assistant in rear view)

As you can probably see, non of these canvas slings for me – instead 3 turns of some climbing rope. If it can handle a 100 kilo block dropping 30 metres I reckon three turns would do! And it did, though the stretchiness was not ideal.

Bring the hoist round the other side push things around a bit and plop! there's The mill in place.

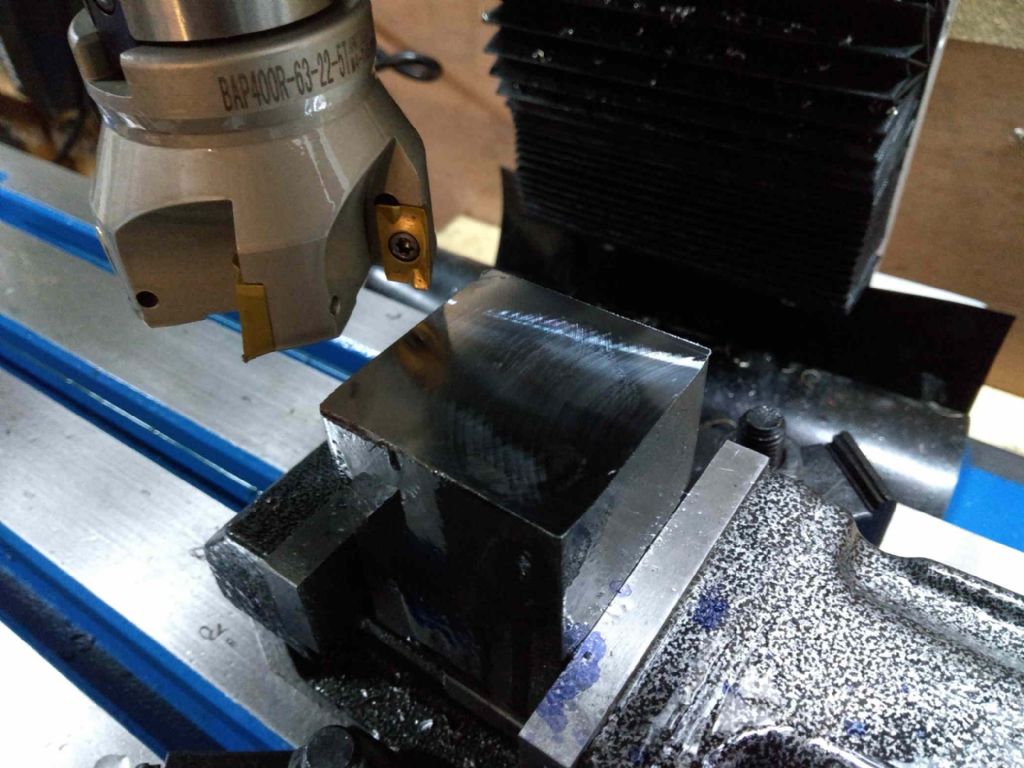

I'd planned on starting small, with a 10mm mill, but for some reason the R8 collet wasn't engaging right, so I jumped directly to the 63mm face mill that you can see in the picture.

The first cut was an absolute delight. No straining at 600 rpm, smooth as silk and a near mirror finish!

Of course, there's still stuff to do. There's a lot of bits to clean, a packing case to dispose of (I suspect I will recycle the plywood as shelf supports). My vice, which was nearly too big for the CMD10 is nearly too small for this one.

But that's for tomorrow.

I LOVE it!

Iain

Edited By Iain Downs on 20/12/2019 18:39:59

Ian McVickers.