Long, boring ramble about a couple of week's shed time. ->

I've got a job that the plasma cutter function of the welder would be handy for but…

The first time I used the plasma cutter thingy on the welding set the fumes blocked up the filters on the shed's computer cupboard and A/C-heater (lungs, what lungs). Made a better filter for the computer cupboard, but wanted something to get the crud out of the shed's air. My old dust extractor vibrated so much that it had worn through the casing of the motor's run capacitor and blown it up along with some of the motor's wires.

I have some 2hp 3ph flange mount motors that I'd been given, so turned down the shaft of one and put a new keyseat in it, fitted it to the dust extractor where the clapped out 1/2 hp single phase motor had gone and got a VFD for it. It doesn't need 2hp, but I have some ideas for variable speed where a howling gale isn't needed.

Wired it all up and tried it out. Then came across the balance problem that had eaten the original motor. Hmm, it needs balancing…

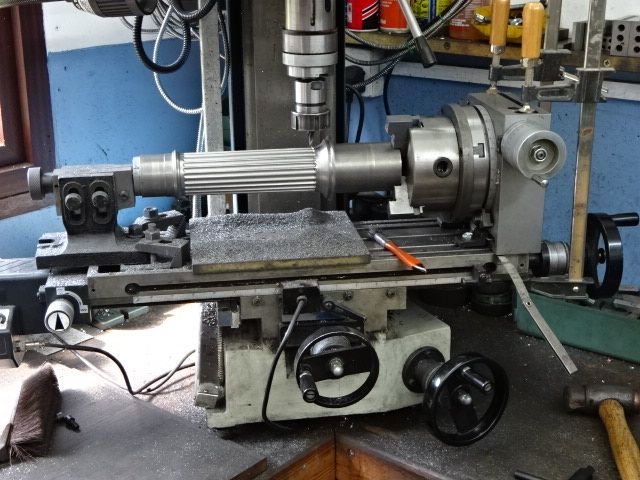

Made a four wheel, single plane, static balancing rig. Tested it by balancing all my surface grinder wheels and then went on to the dust extractor's fan. Worked out where to TIG weld a washer onto the fan to balance it, then discovered that the little plastic lever that works the TIG welder's torch switch has gone walkies. Came in at that point tonight. I'll mill a replacement out of a bit of ally tomorrow.

Curiously, a grinding wheel that had been giving less than perfect surface finish turned out to have a lousy balance, whereas one that had produced good results appeared to have been close to perfectly balanced.

Balancer with grinding wheel:-

Balancer with fan and balance-weight washer:-

JasonB.

JasonB.