Started off having a clear up but got side tracked into a job that's wanted doing for over 2 years.

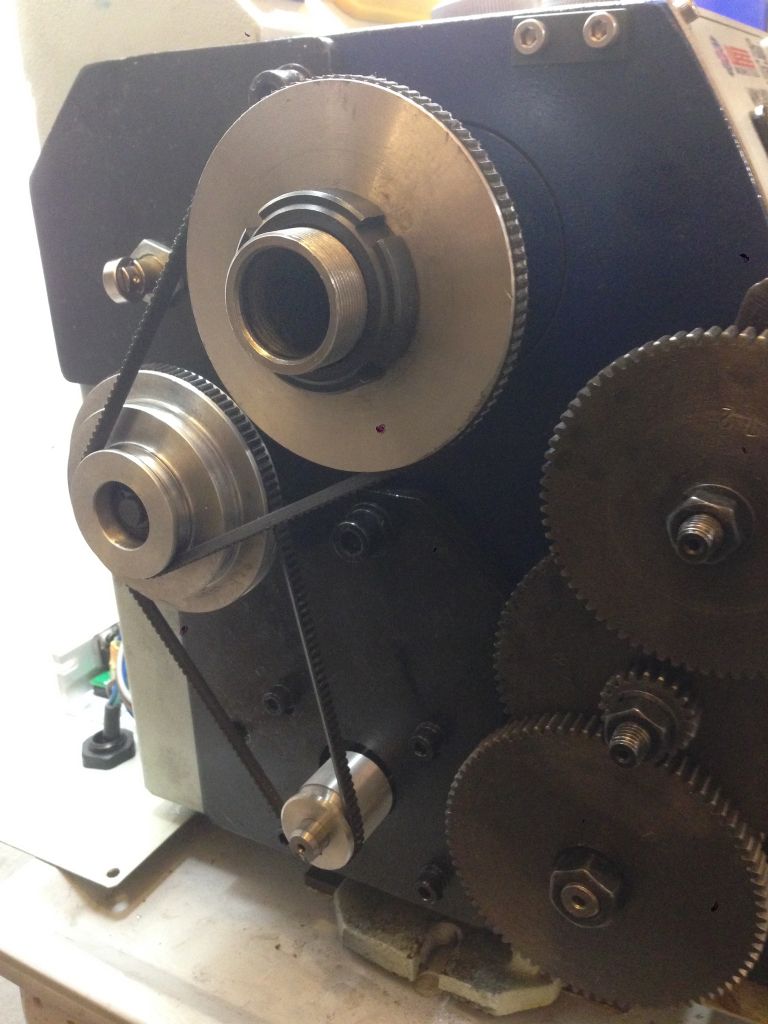

When I bought my big mill , a WM40 from Warco it came with a two axis DRO fitted but I swapped the 3 axis read head off my old mill onto this which was OK as I use a vernier type bar on the quill but I had a spare scale kicking about to fit so in the clean up, found and and started to fit it,

The only place to mount this was on the electrical cabinet at the side but as I guess although it looks square it's not plumb in both plane because of the column tapering so a lot of winding up and down and shimming before I was happy.

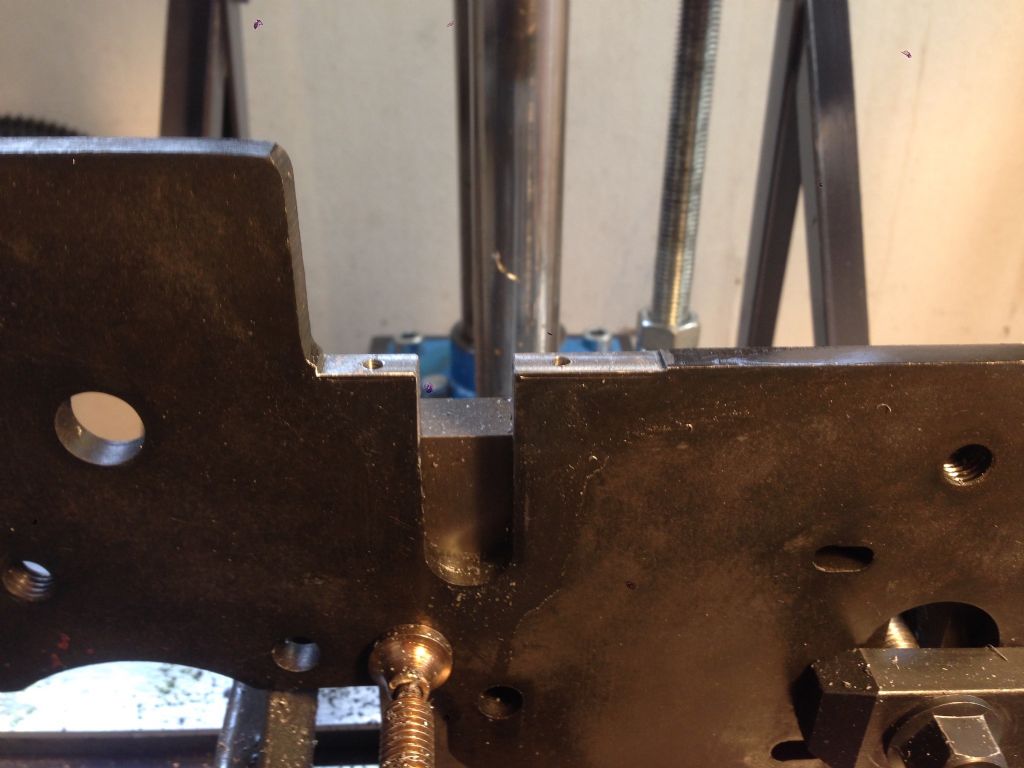

This mill has a three phase motor driving the knee directly which is one of the main reasons I bought it as it's the next size up to a standard Bridgeport but they had been very conservative in fitting the stops for the knee motor and I was loosing out at least 3" top and bottom under power although I still had this movement if I wound it by hand.

So a re measure and a bit of drilling and it stops just short of the physical stops. So 433mm on knee movement under power and can just scrape 450mm if I hand crank to the physical stops.

So all in all a productive day and we won't mention dropping a very large box of Coventry Dies and having to re-sort them all out off the floor.

I said we won't mention that bit.

Edited By John Stevenson on 05/03/2017 22:56:59

mechman48.