An unusually productive day today.

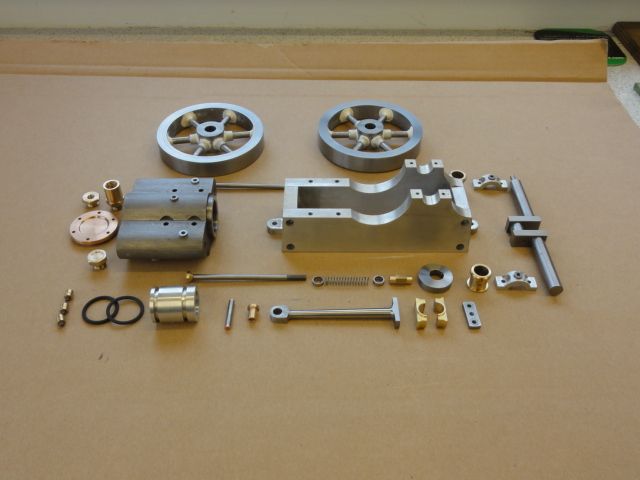

I've stripped my lathe down and have been Wyattising it

This fairly nasty piece of work is to keep swarf out ot the saddle gears. In my defence, I broad my fretsaw blade after doing the outside and can't find the 10 I know I have somewhere. The inside was done with a dremel hence the erratic nature (I know – bad workman and so on).

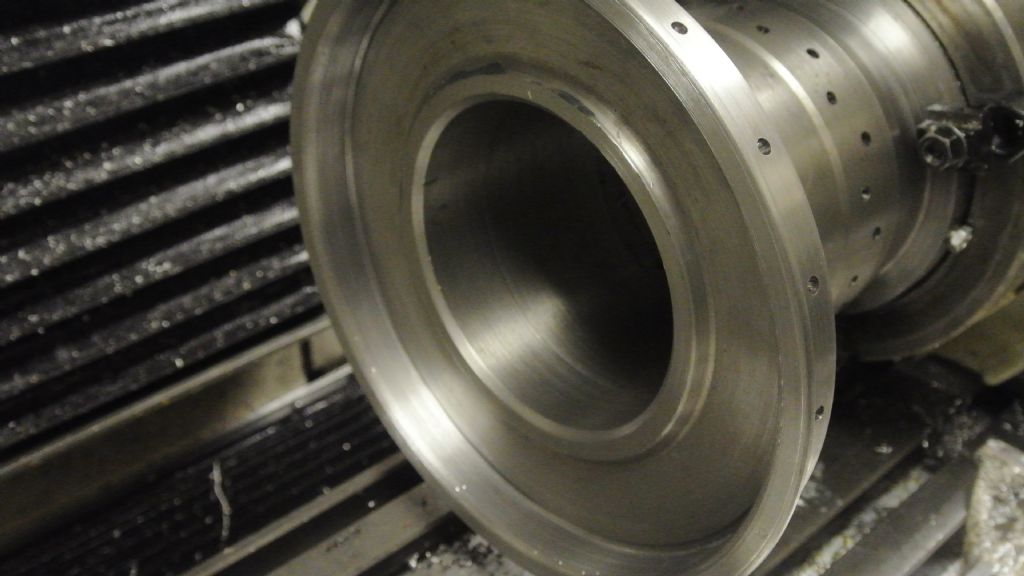

The next thing on the lathe is to replace the spindle which I probably mucked up when removing it to replace the gears in my first act of machine destruction.

To do that I'm making a press. A bit of 12 inch girder from the scrapyard is the starting point. Chop out some of the middle…

A strikingly challenging task which has consumed 2 angle grinders half a dozen milling cutters, a hacksaw blade, a considerable amount of time and a very large amount of bad language.

Today I was boring out the hole in the top with a core drill. The girder *just* fits under my mill, so I was able to mill a flat on the top, but no way will it get a chuck there. and I'd burn out it's little motor.

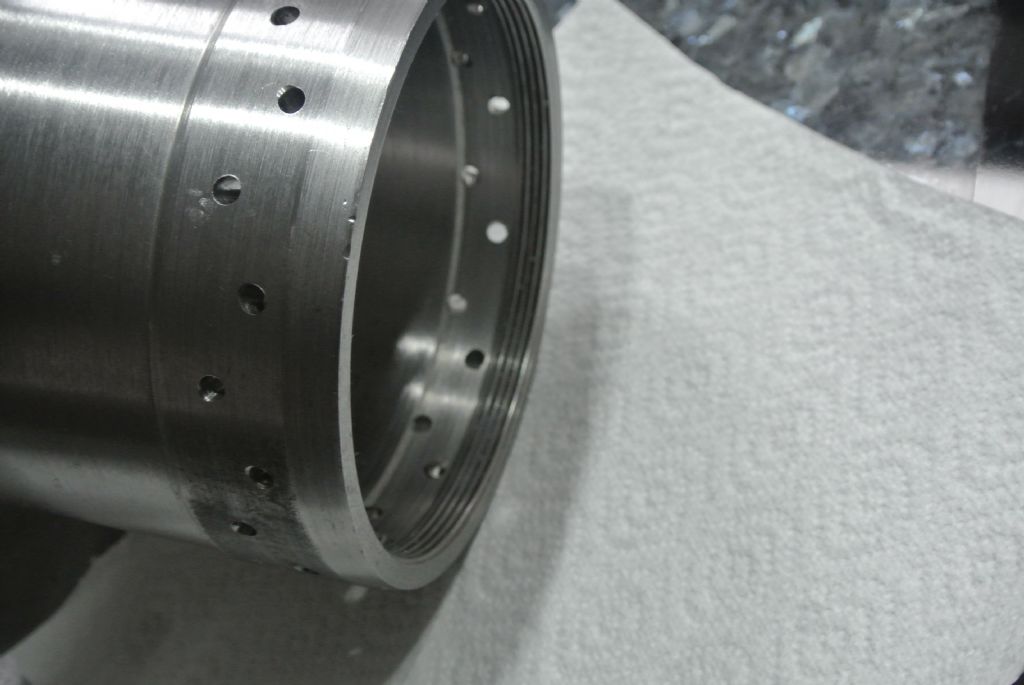

This worked much better than I expected, though it took 20 minutes or so. I'd managed to get a 10mm hole through with a milling cutter, so I made an 10mm/ .25 adapter for the arbor which work quite well (which is what I've been waiting for to get the lathe back together).

core drill top right, core on the left and the adapter (the drill bit wasn't in of course) at the bottom.

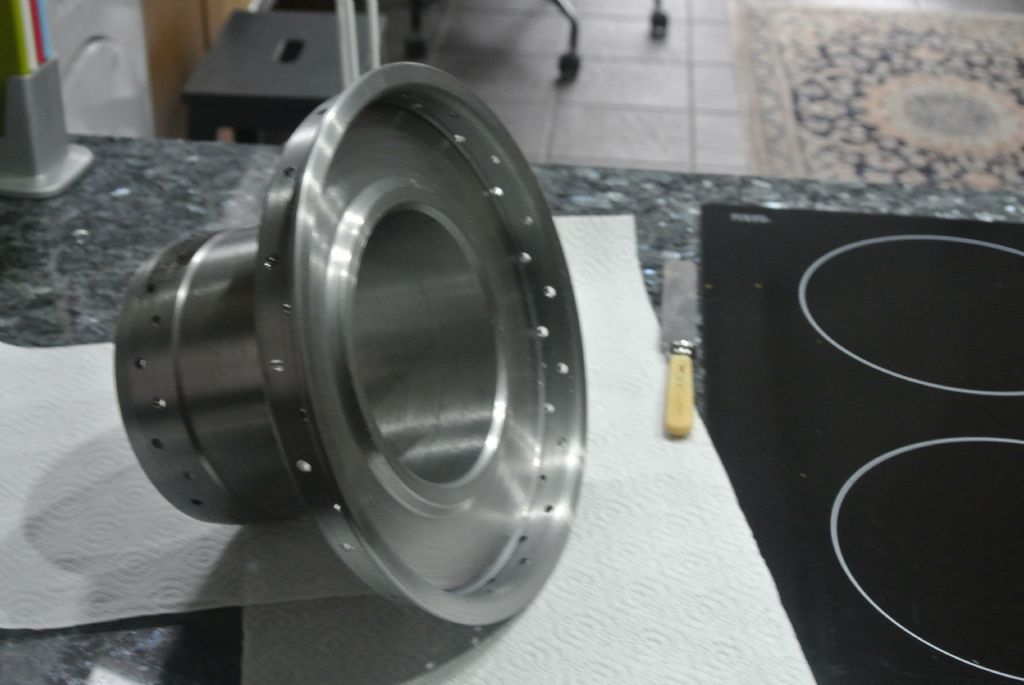

I did try and cut an M20 rod on my lathe, but this was not a success, so I invested in one made by a professional.

I've got another scrapyard steel block which I will mill out to take an M20 nut and bolt it into the recess. Hey pressto! (sorry).

Iain

mechman48.

![verticalslidemount[1].jpg verticalslidemount[1].jpg](/wp-content/uploads/sites/4/images/member_albums/141785/725296.jpg)

![verticalslidefitted[1].jpg verticalslidefitted[1].jpg](/wp-content/uploads/sites/4/images/member_albums/141785/725295.jpg)

![millingmotor[1].jpg millingmotor[1].jpg](/wp-content/uploads/sites/4/images/member_albums/141785/725299.jpg)

![millingmotor2[1].jpg millingmotor2[1].jpg](/wp-content/uploads/sites/4/images/member_albums/141785/725298.jpg)

![makingtestpiece[1].jpg makingtestpiece[1].jpg](/wp-content/uploads/sites/4/images/member_albums/141785/725297.jpg)