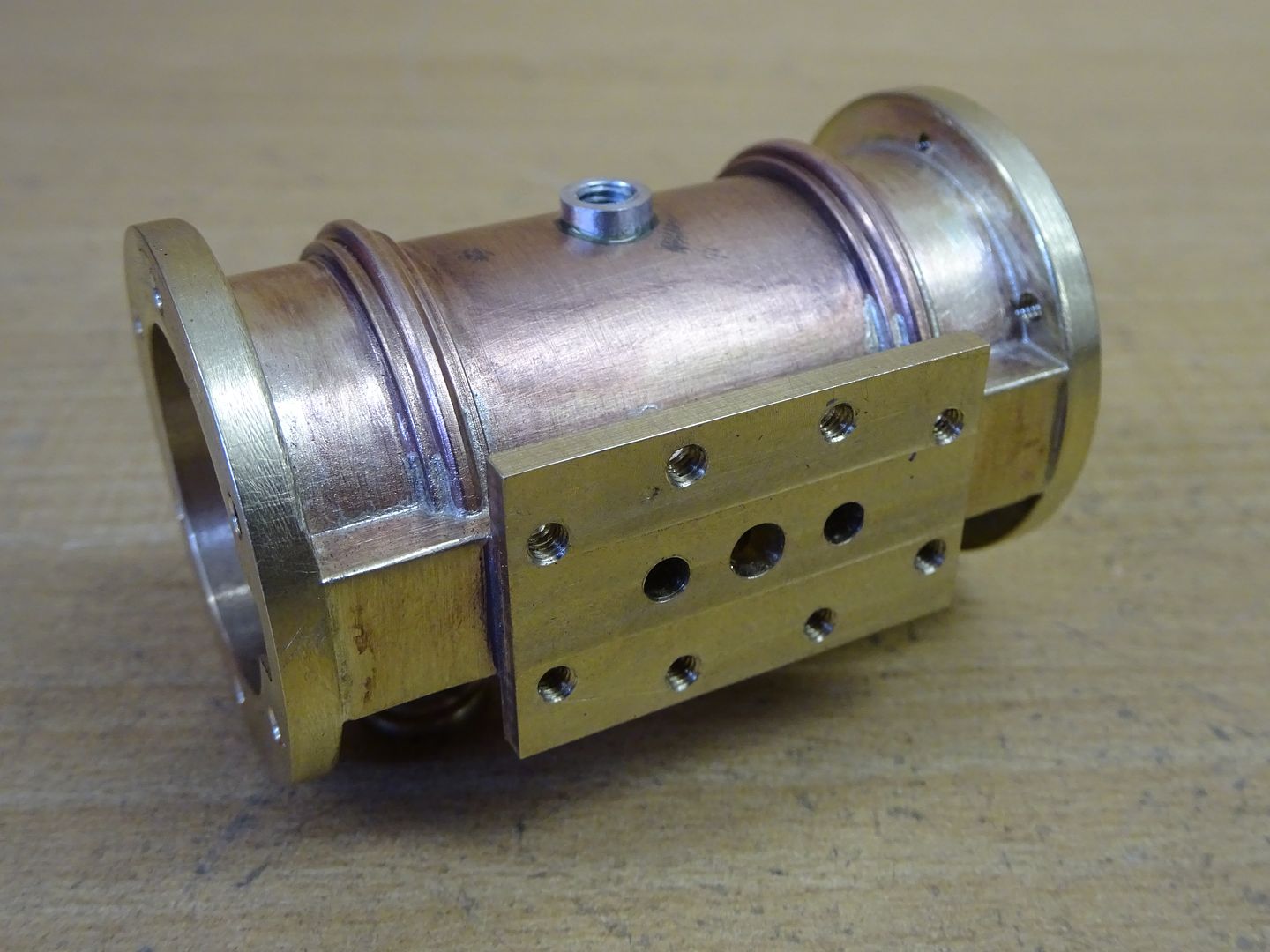

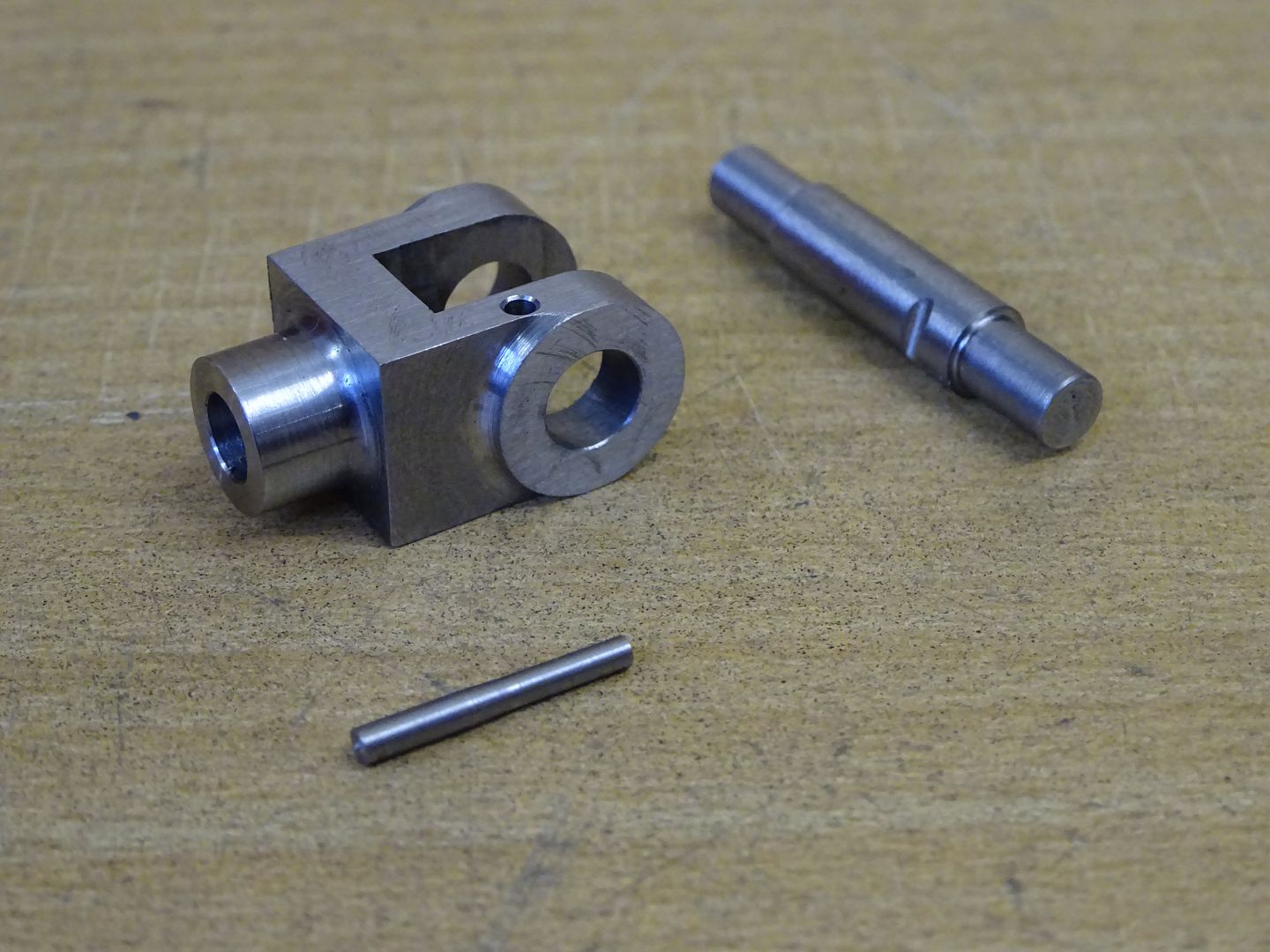

Here's a little loco part:

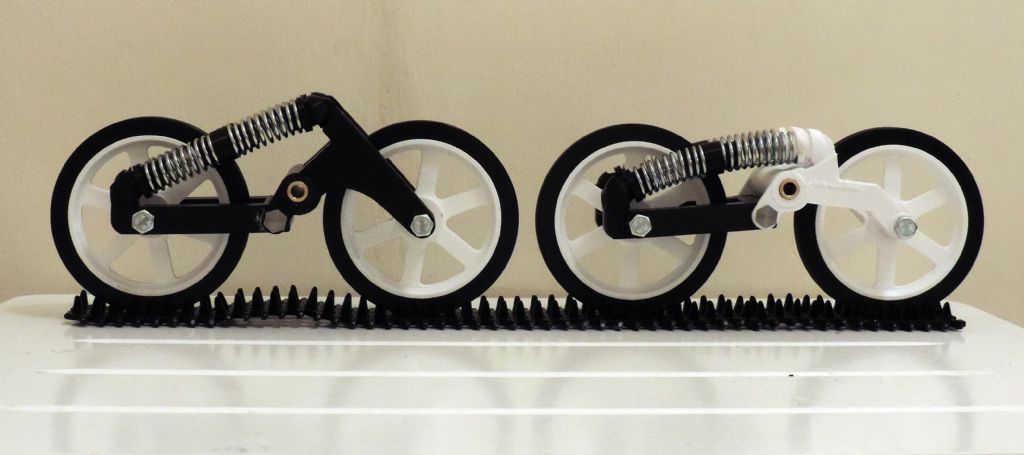

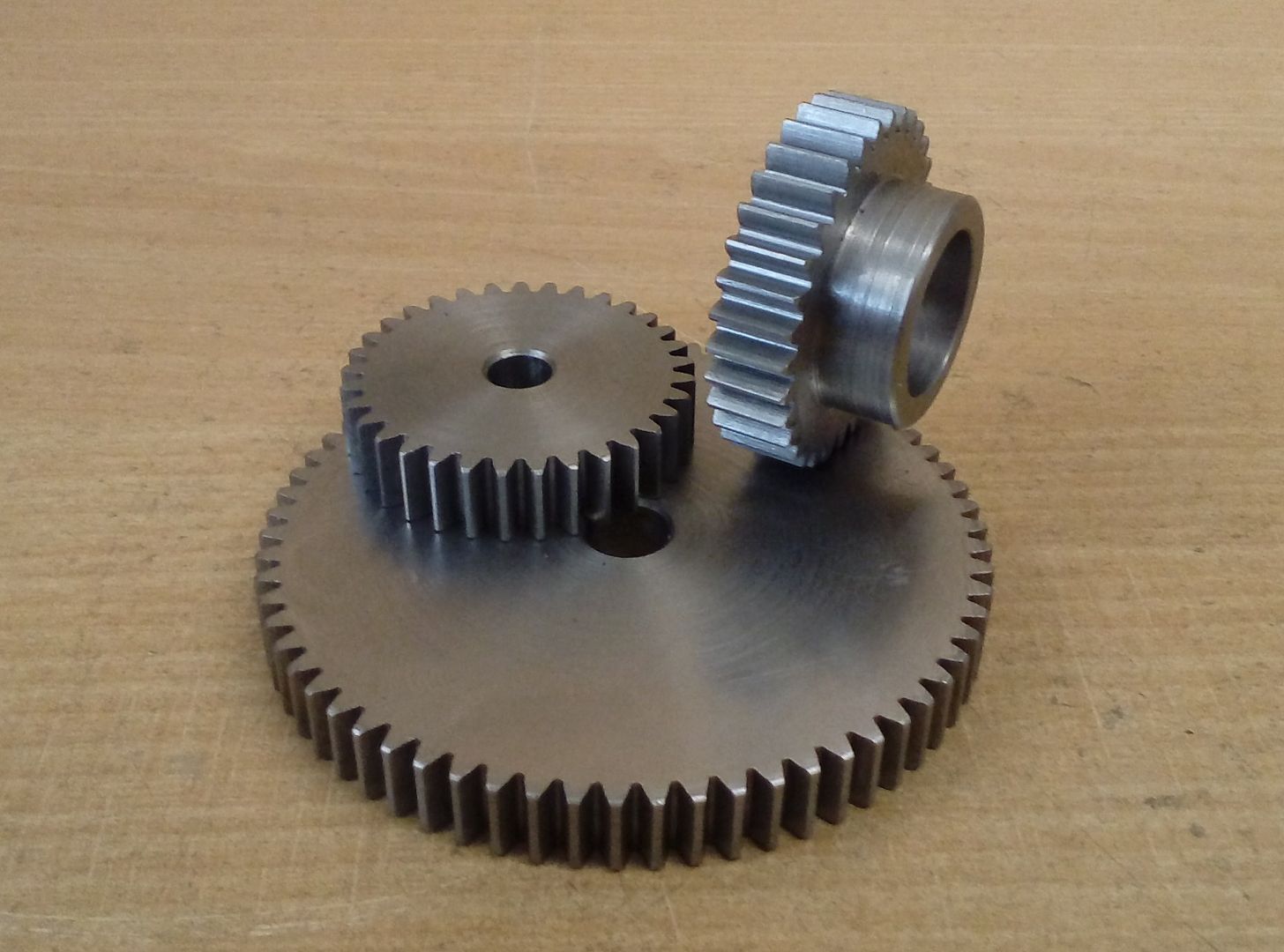

It's one half of the grid section of a an EMD FT loco dynamic brake housing. Needs one slit across the middle to .01 with a .008 slitting saw and before I can try casting it. I believe this is a phase III version as the locos it will go on were made in 1944. It's N scale (1:160th) and part of a suite of parts to represent the much modified Northern Pacific versions that roamed Western Washington right up until 1970 and the BN merger. A friend wants to have all 11 ABBA sets for the 1955 Sumas branch layout he is preparing to build. I had previously made some of the parts out of Styrene to fit the IMRC model but decided to do all new masters in brass. The little flange is .004" thick to (hopefully) ensure it casts. The grid was done manually with a .004 thou engraving cutter but other parts with trickier organic surfaces have been or are being done with CNC. Did the later number boards and an aborted injection mould that way. The pilot is a bit of a pain and testing my ability to draw the surfaces. I think I am going to fix my probe and use it to figure out the mounting area on the IMRC shell. Present work is centred around building a buck and then forming the metal (.015" ) and laminating .002" shim embossed with the bolt heads. There are easier methods but I need to use this method elsewhere so I'm trying to work out the bugs where possible. Need to work on my soldering amongst other things and one of the reasons I ran back to something easy for this afternoon's work.

Here's a photo of one of the units in question care of Rick Horne:

Canada is just behind the shed. My house only an hour or so bike ride away.

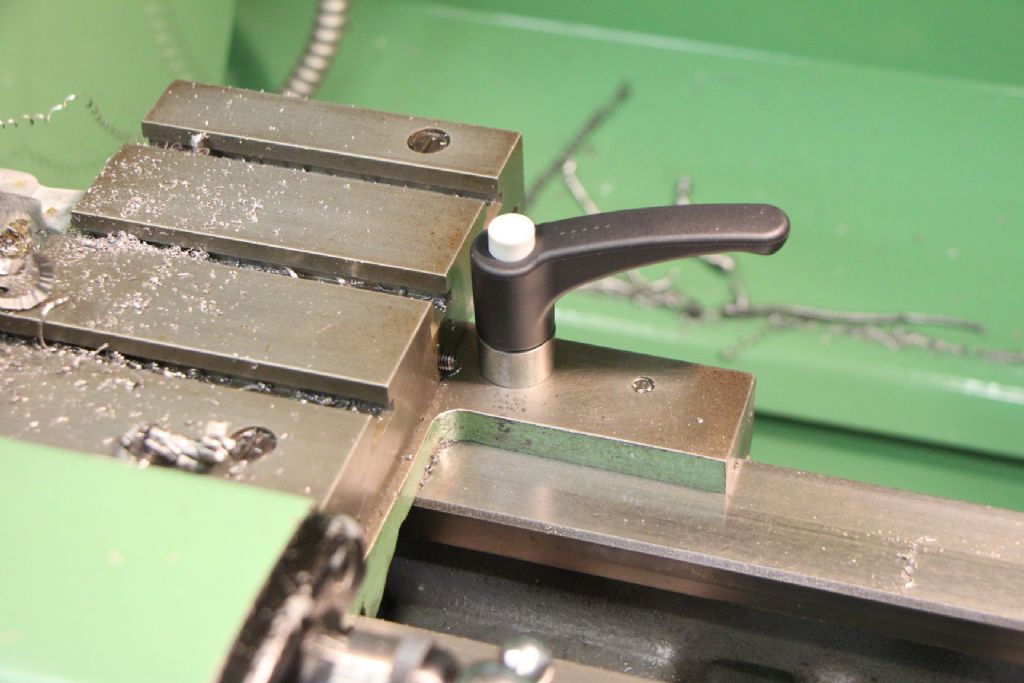

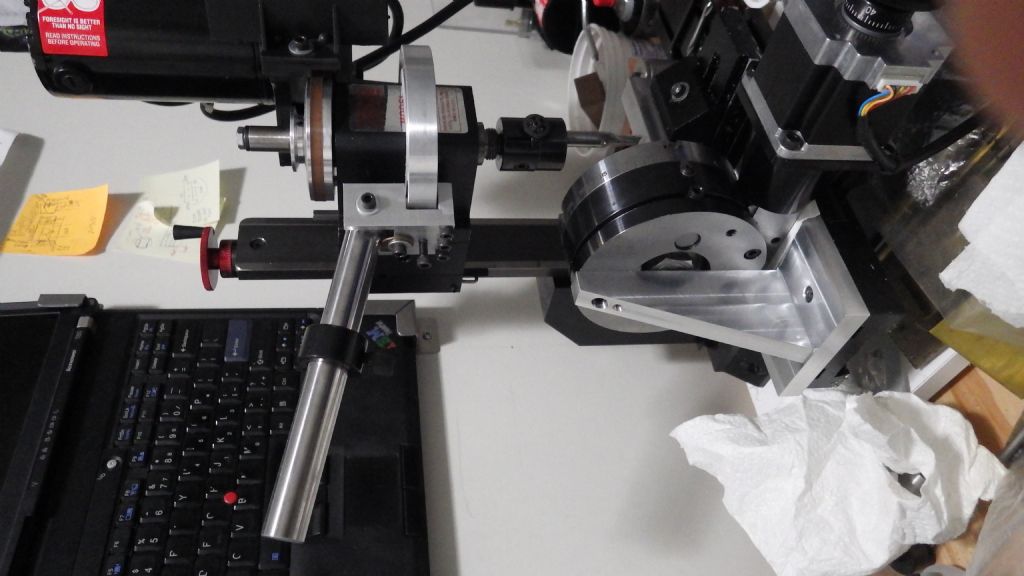

Not today's output but I made a pair of these right angle brackets for my mills. Just a rough copy of the Sherline ones – that way I know they fit!

Will have to make an adjustable too one as the cast iron one I have is too heavy to keep taking home from the shop in my pack.

Andrew Hutchinson

BC Canada

Edited By Andrew Hutchinson on 30/01/2017 06:33:50

Edited By Andrew Hutchinson on 30/01/2017 06:34:16

mechman48.