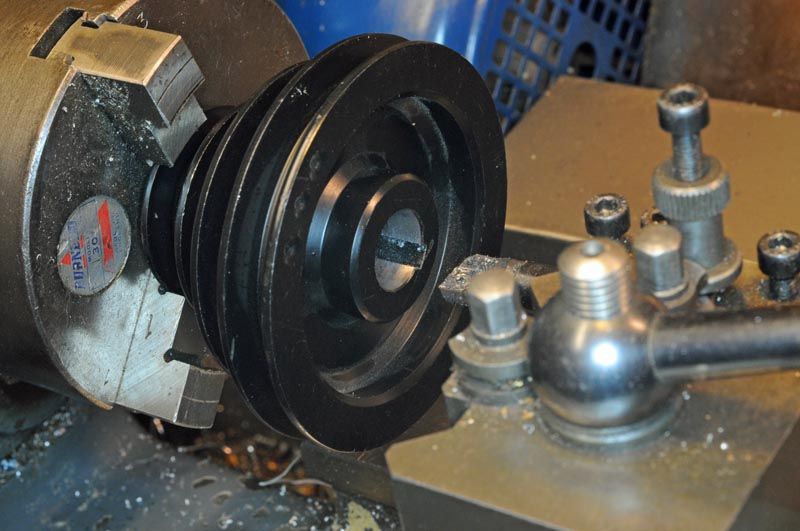

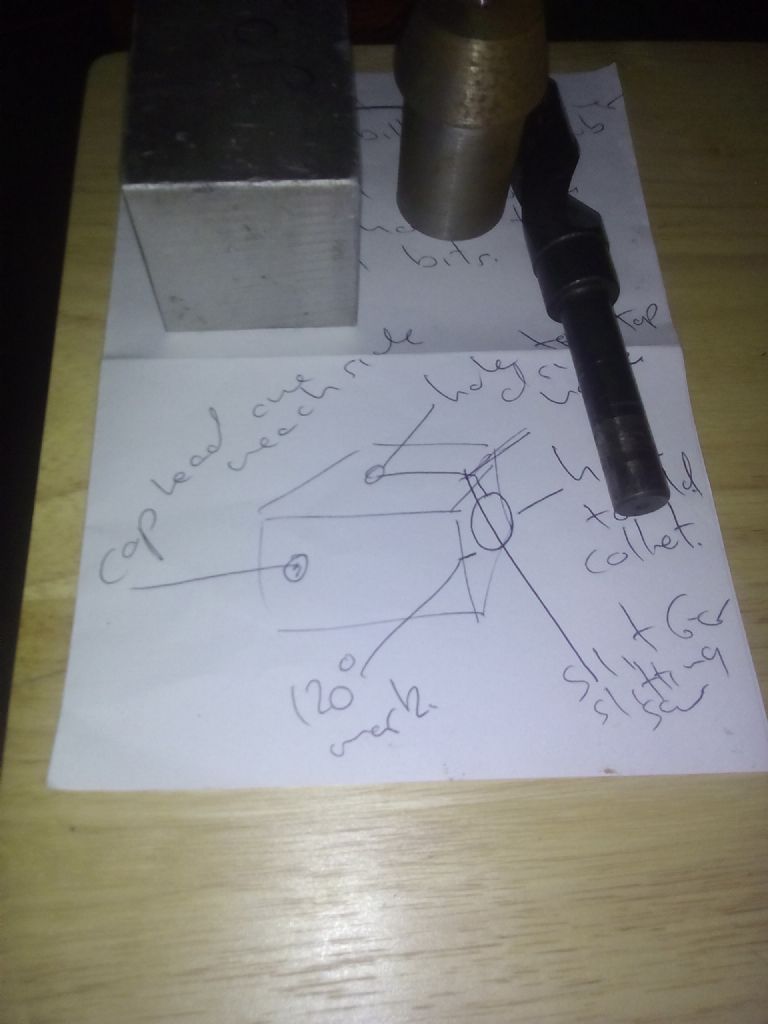

Living on the edge today. I've taken the plunge to convert my drill to 3 phase VFD, via some EBAY purchases. The 3 phase motor has 19mm shaft instead of the 16mm on the original motor, so the motor pulley needs boring out. This was the only way I could think of to hold it. Precarious or what? And it's an interrupted cut because of the key way.

Remarkably drama free  . Pulley is CI.

. Pulley is CI.

Inverter was a S/H industrial cabinet mounting unit, pre-programmed and wired to the remote. I've installed it in a tin box from IKEA mounted above head height.

The remote unit replaces the original ON / Estop

Motor appears to run at 900rpm at 50HZ and the inverter goes from 0-60HZ. Top speed is slightly less than before ( 2066 rather than 2580) but I can put a 1/2" drill through steel with the pulleys left on the highest speed so torque is adequate at the lower speeds. I use the Pillar tool for small drills anyway. So, dead chuffed.

And, further to previous discussions: The inverter doesn't trip the RCD  . However, with the drill powered up, I switched on the mill – lights out

. However, with the drill powered up, I switched on the mill – lights out  . Seems the earth leakage is adding up but I can live with that – I just have to remember not to switch them both on during Strictly.

. Seems the earth leakage is adding up but I can live with that – I just have to remember not to switch them both on during Strictly.

Cheers,

Rod

JasonB.

JasonB.