Made some progress on the fabricated Versatile Dividing Head after a bit of a hiatus. Got the last ball handle done. Glad to see the back of those critters! My homemade ball turner was never intended for stuff that small.

So it was on to the 60-tooth gear. Now if you buy the kit, you get a nicely made helical cut gear that engages nicely with a worm to provide the compound indexing. But this being a scrap-box special, I am using an old 60T change gear off an unknown lathe. Maybe an early Myford or Raglan? I dont know. The worm will be mounted at a 4.5-degree angle so it meshes correctly with the straight-cut gear. Maybe later on I will use the completed VDH to make a proper helical gear. Maybe.

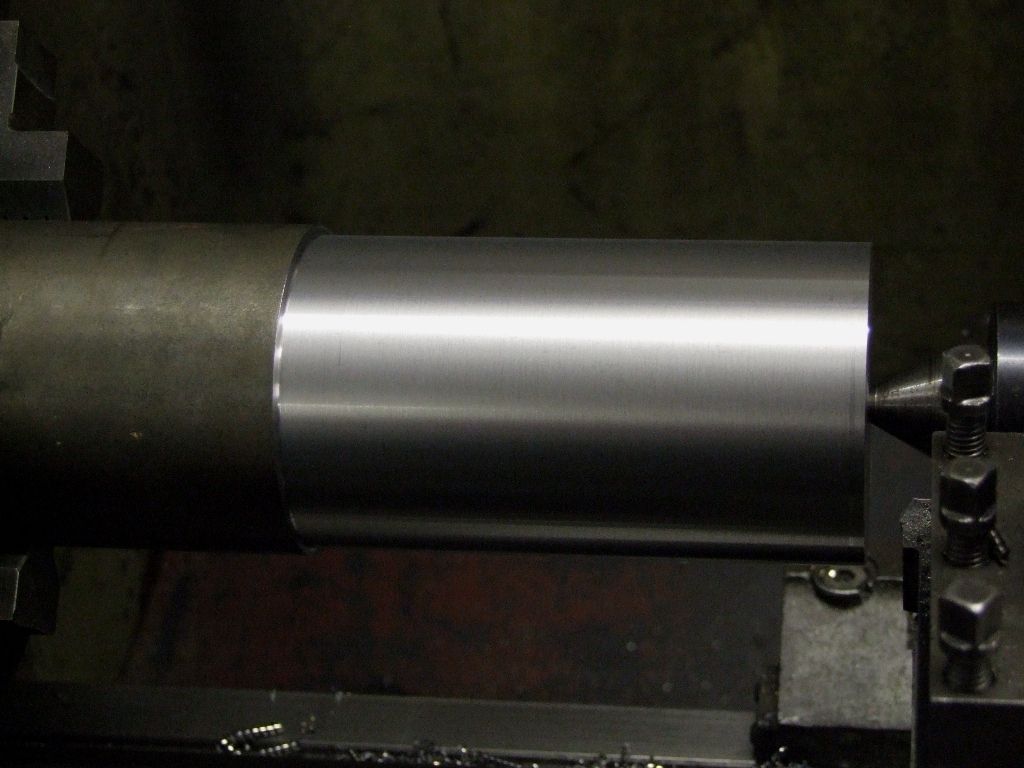

Problem using this gear for now is that the gear is cast and has a recess on each side. BUt one side at least needs to be flat and without recess in order to be able to drill the 24 holes used for direct indexing with a spring loaded plunger. OK says I, machine the recess out nice and round and square, turn up a suitable large washer to fit and loctite it in place before machining the face nice and flat all across.

Done, but my piece of scrap used for the washer had a big dint in the middle, which left a slight .005" deep "witness mark" but, hey it will be covered by the retaining nut.

I cut the 5/32" keyway (good old GHT could not go with plain old 3/16 or 1/8" ) using a boring bar with the toolbit ground to 5/32 wide and running the carriage back and forth with the rack feed as I fed the tool outwards in two-thou cuts. Actually did not take that long to do and came up quite nice.

But on assembly, I still think the recess on the back side of the gear needs filling in, just for aesthetic reasons.

After that it will be on with cutting the keyway in the spindle, and drilling the locking holes and spanner holes on the gear retaining nuts and the main spindle collar.

Edited By Hopper on 09/07/2016 12:37:57

Edited By Hopper on 09/07/2016 12:41:46

Edited By Hopper on 09/07/2016 12:44:07

JasonB.

JasonB.