Posted by JasonB on 19/06/2016 07:27:07:

……always like to see what you have been upto with the Britan or as there were only a few was it not worth setting up for a batch?

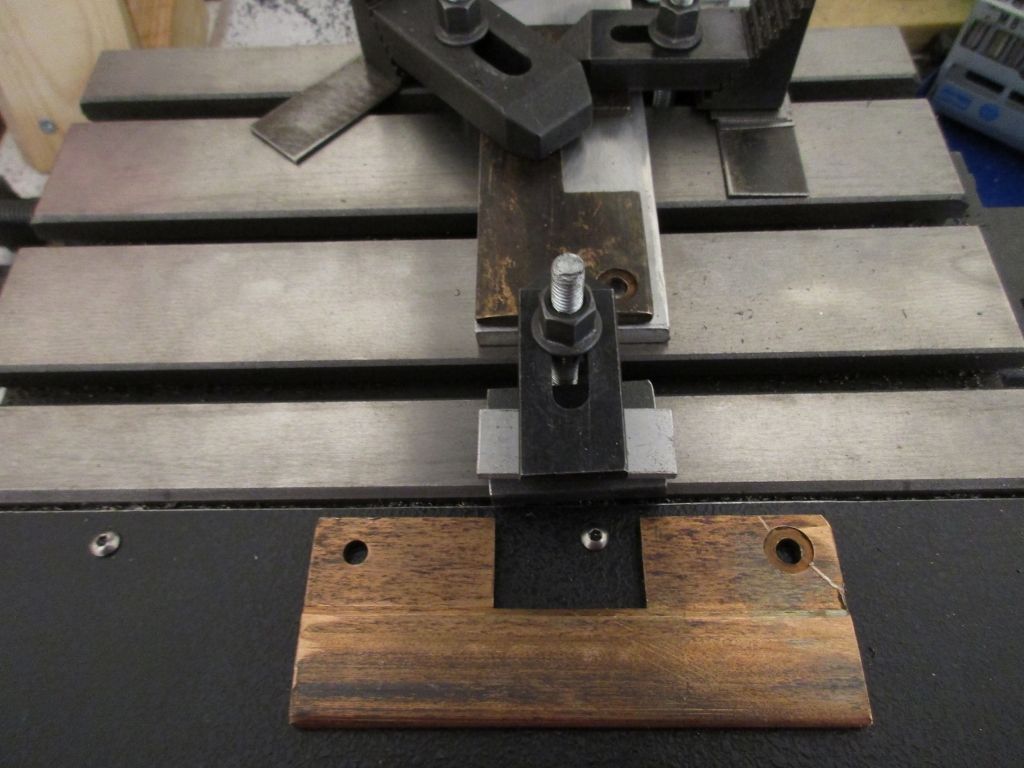

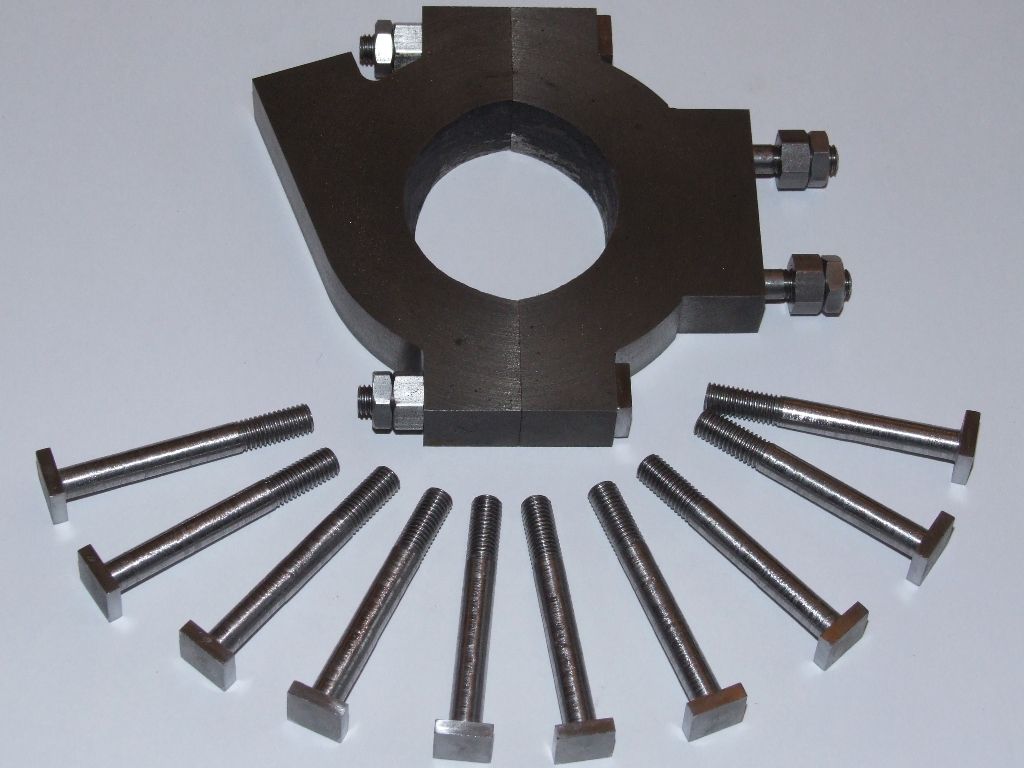

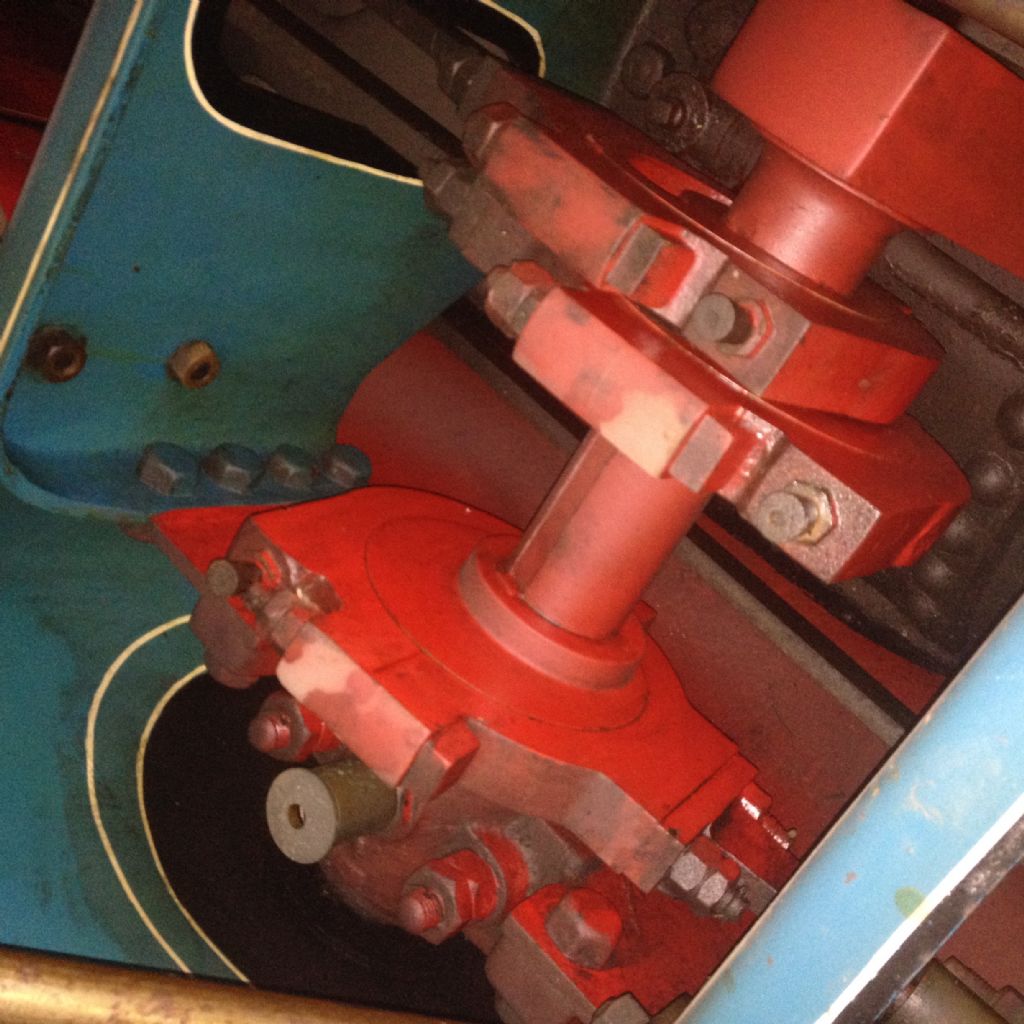

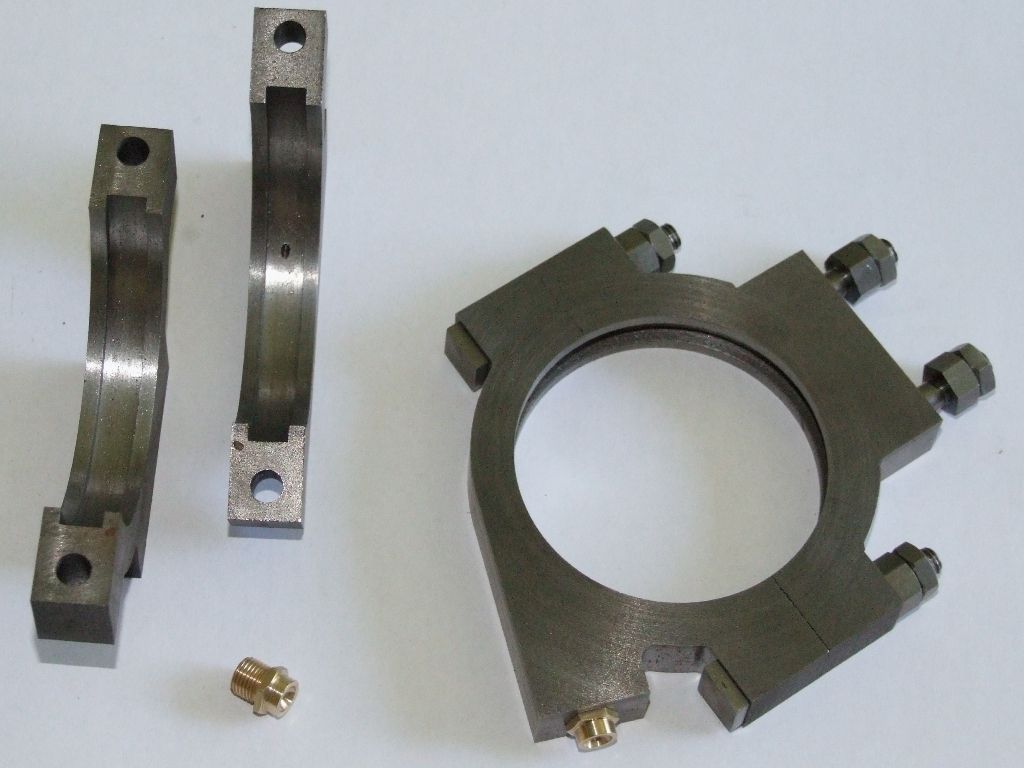

Yes, I did use the Britan for most of the operations. However I used the Bridgeport to reduce the heads from 1/2" square. This was necessary due to a foul up in the position of the hole on the eccentric strap. If left at stock size the head would have been proud of the strap. I'm not really happy with the bolts, somehow they don't look right, I think the heads are too thin? But I'm not sure I've got the enthusiasm to make them again. Here are the bolts:

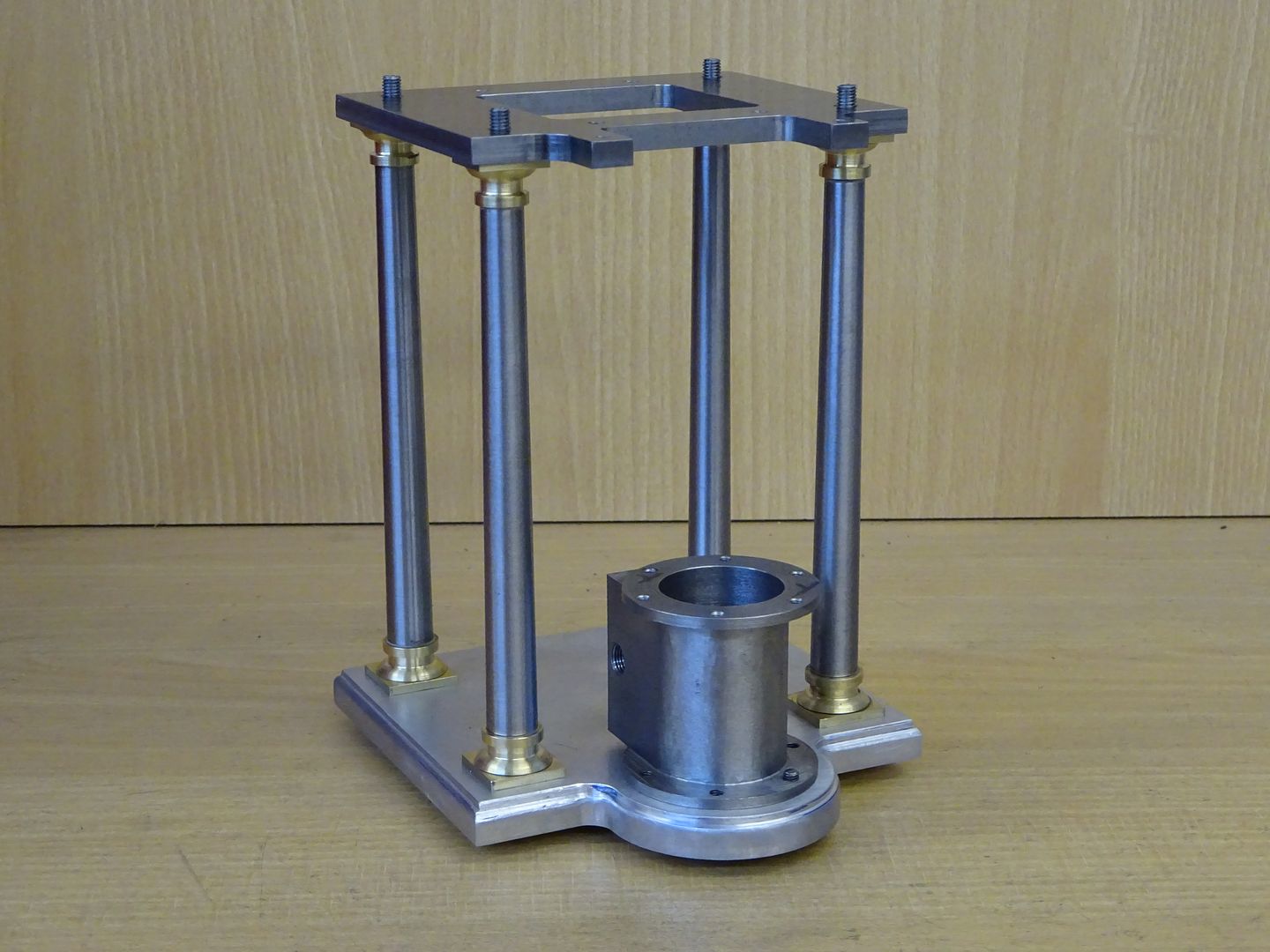

The nuts and studs were made ages ago, and I profiled the outside of the straps last week, on the CNC mill.

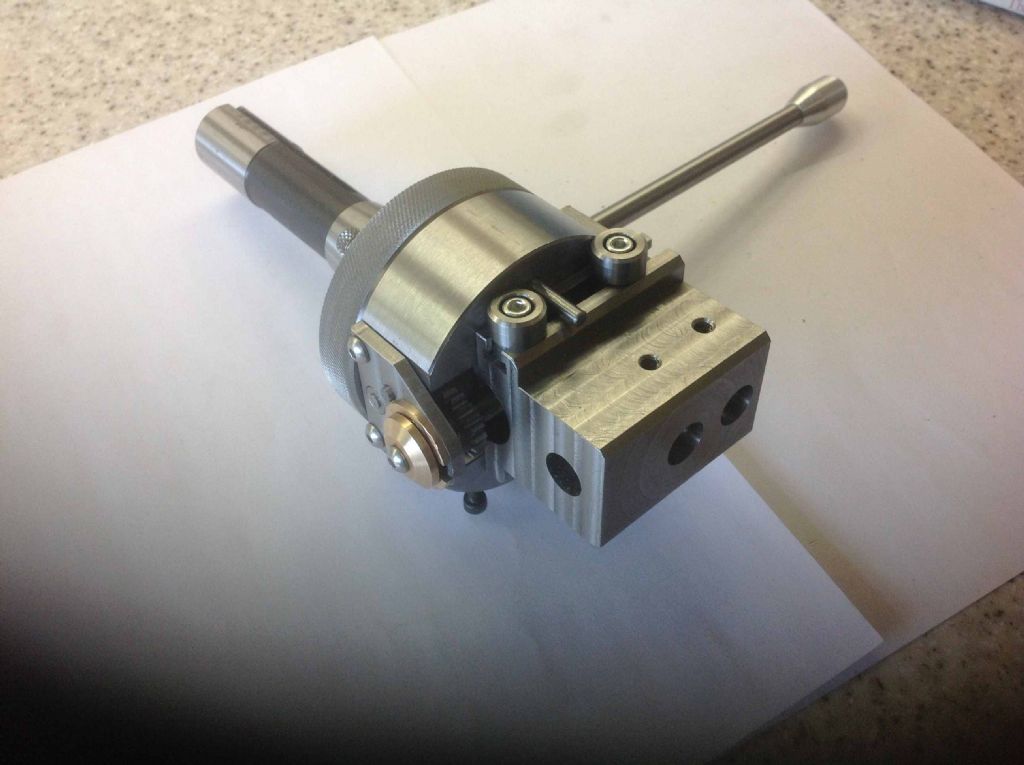

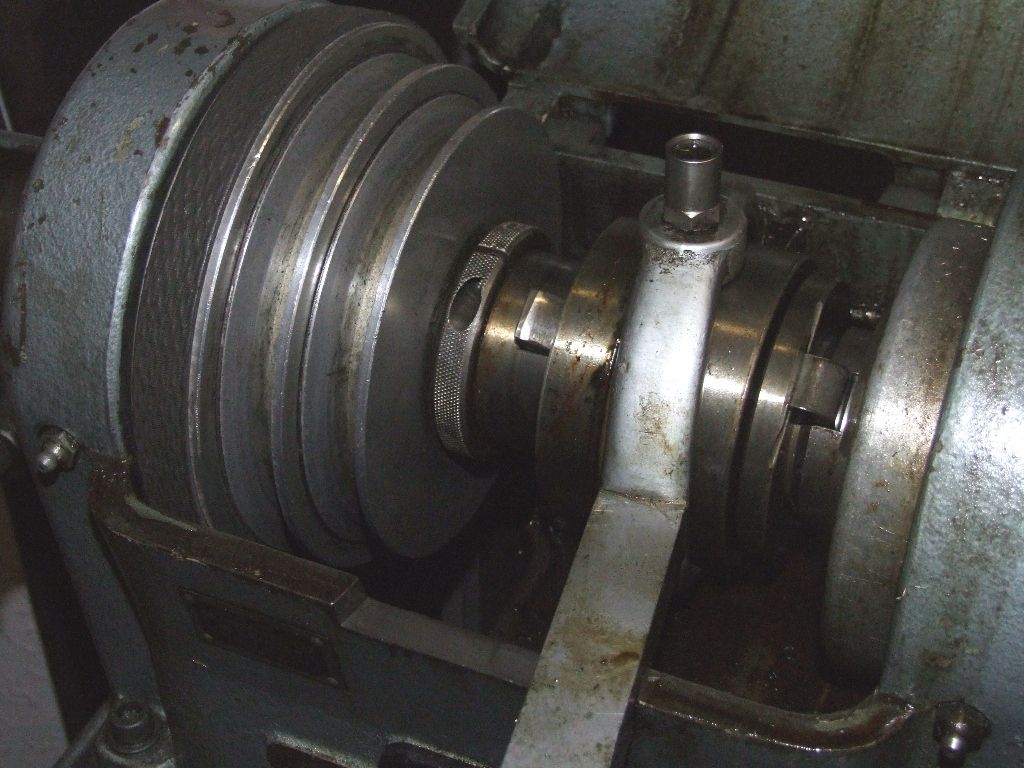

I also had a screw failure on the Britan.  When changing collets from 1/2" square to 1/4" round the screw that clamps the collar that sets the force required to operate the collet closer snapped. It doesn't stop one using the lathe, but will need to be replaced. I'm hoping I can get the broken bit out without having to dismantle the headstock:

When changing collets from 1/2" square to 1/4" round the screw that clamps the collar that sets the force required to operate the collet closer snapped. It doesn't stop one using the lathe, but will need to be replaced. I'm hoping I can get the broken bit out without having to dismantle the headstock:

The offending collar is the knurled one in the centre, just to the right of the pulleys.

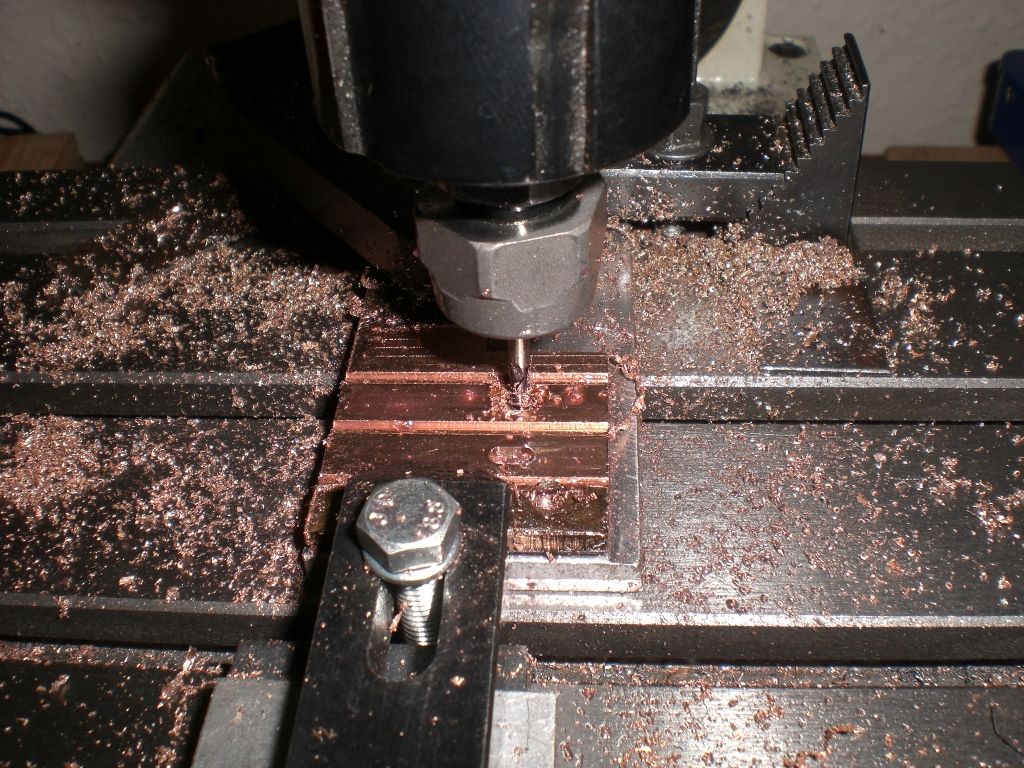

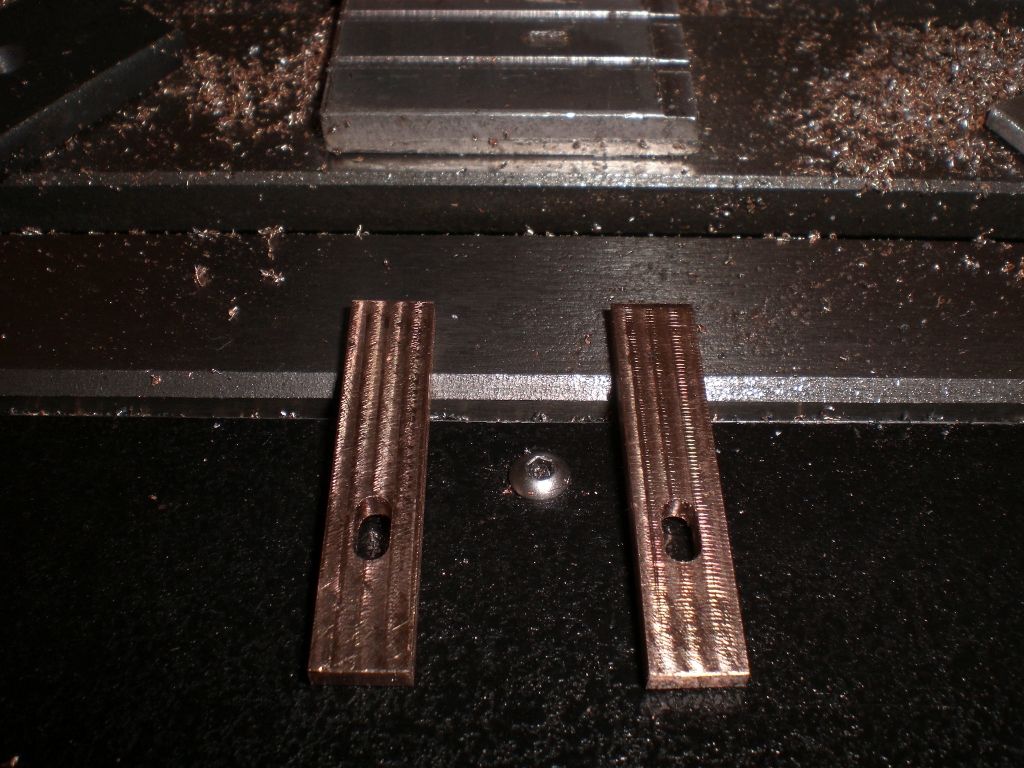

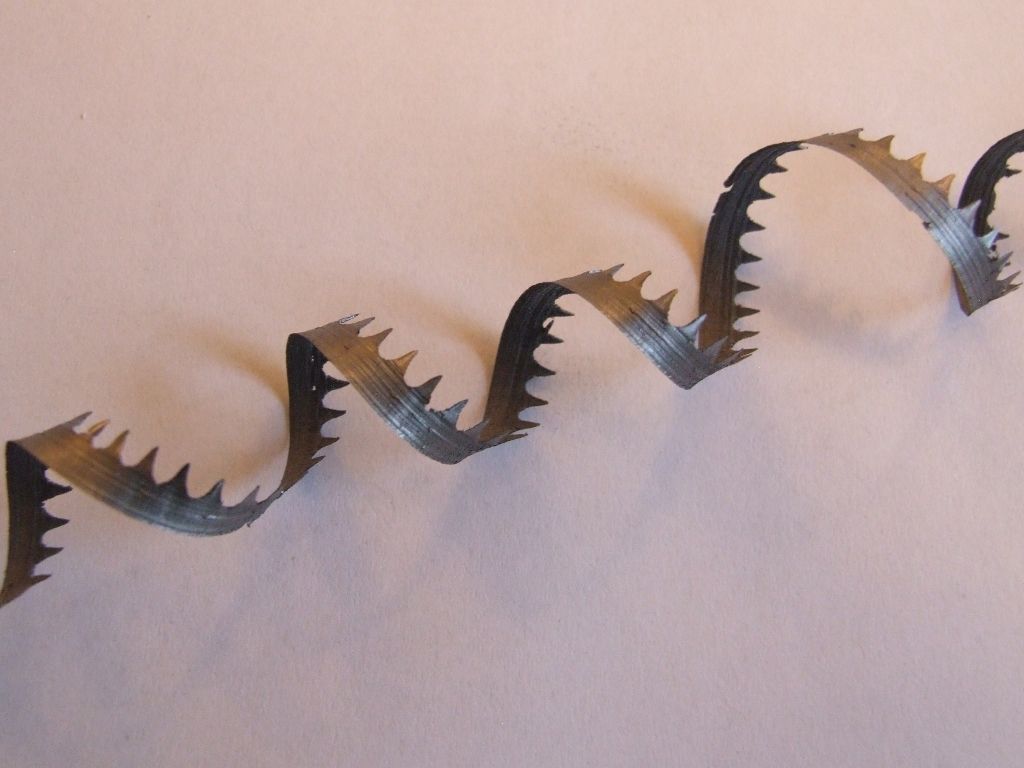

On a more positive note the swarf that came off when reducing the 1/2" square stock to 1/4" diameter, in one pass, is rather pretty:

Although it varies, the thickness is around 12 thou.

At least I've cut the grass today before it rained, spent ages weeding, and cleared out the gutters sufficiently that I'm no longer embarrassed to call out the required gutter cleaning and repair company.

Andrew

JasonB.

JasonB.