Hold in 4-jaw , with spigot facing outwards and get it running as true as possible, use packing behind the flange to keep it at right angles to lathe axis. Remove packing and true up & face the spigot, you really only need the larger spigot dia so the small bit could be sawn off.

While still in the 4-jaw face the flange to leave the boss that goes into the cylinder, use the cylinder to gauge the size as you get close . Also drill and ream right through 3/16". This will keep the 1" dia and 3/16" hole concentric and at right angles to the top face of the cylinder.

Now hold the part by the spigot your Bison 3-jaw should be good enoght for this and face the gland boss so it is 7/16" from the machined flange face, counterbore 5/16" a drill will do for this. While held this way turn the top of the flange until it is cleaned up, leave the raised area around the gland boss as cast.

Finally hold it the other way around and turn off the chuck spigot and face the 1" dia, not critical if its a bit less than the 1/16" long

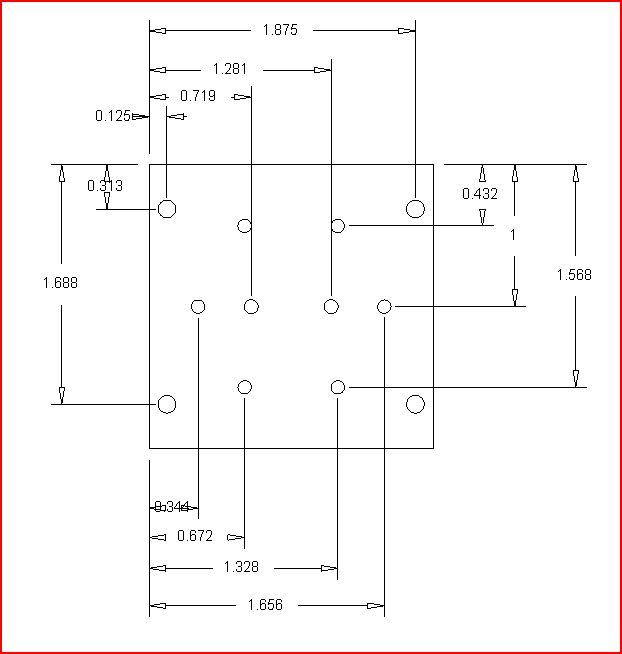

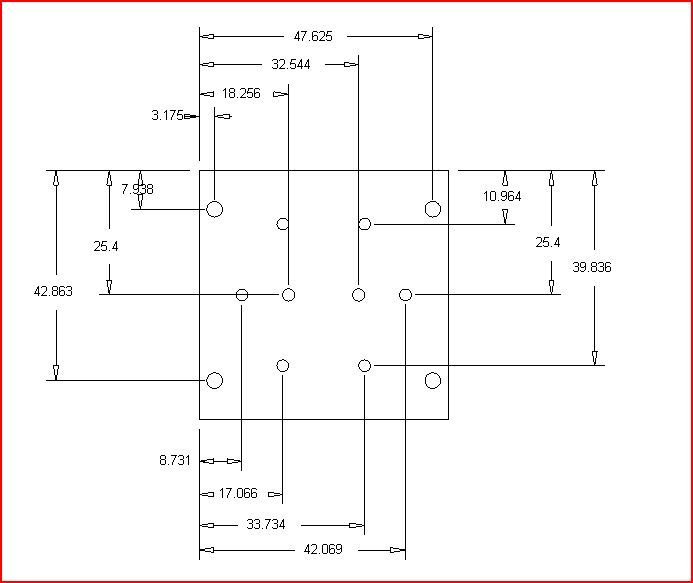

Finally mill the 4 edges square measuring off the 1" dia, then set the part true under the mill spindle and use co-ordinates to drill the 10 holes (zeuz tables will give you the calculation for the 6 holes)

Nick_G.