Hi guy’s,

When Graham first mentioned this characteristic it rung a bell as I was sure I had seen it before on material used at work. I was not sure however this would be on all ‘Cold Drawn Steel’ as I could not remember ever having a problem with basic Bright bar. I can’t recall being bothered by it at home either.

That is not to say it’s roundness and dimensional tolerance can be taken as gospel – if you want that then you have to go to PGMS – but merely that it’s much better suited to popping straight in a three jaw than ever black ‘Hot Rolled Bar’ is.

Looking at Andrews image this is exactly what I can remember so have been out to the workshop tonight and had a real good ‘root’ in the metal stock to see if I could find something similar.

About six weeks ago I purchased from my last company several lengths of En1a in varying diameters. Taking a close look at them there is no real indication of this helical characteristic. To me they look as I expected for ‘Cold Drawn’ . Going through the ‘stash’ however, I find that it is reasonably pronounced on some pieces of EN8 and EN34. What stainless I have though shows none.

My recollection (and that is becoming a struggle these days) is that this was most prevalent on bars of ‘tougher’ steels. For example we used to order B01 Arne tool steel both in black and bright finish and I’m sure that this (the bright) was where this helix was most prominent almost as if it had been ‘coarsely’ ground though that’s not implying that it was!

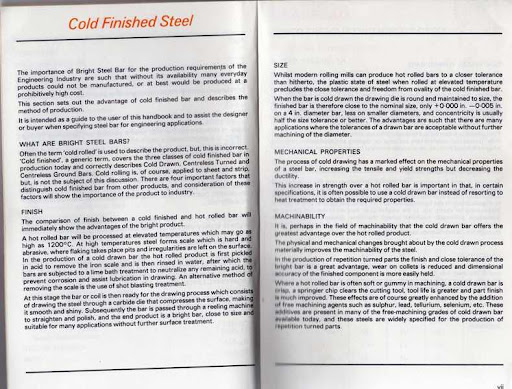

Macreadys handbook gives a good description of the proccesses – I see Graham they denote ‘Cold Rolled’ as an incorrect term but that may, as you say, be an Americanism.

Some time back I was given some EN24T offcuts by an ex work colleague whose entire works is CNC out put. All the EN24T that I had used todate had been as I would have described as cold drawn but this had a very bright – almost highly polished finish. I haven’t examined it close enough to say whether it is ground or turned but it is extremely smooth. When I asked about this I was told that the material came in as such for use in the automatic barfeeders.

Could it be then that the ‘helical marked’ material is as described in Macreadys as Centreless Turned as opposed to cold drawn? possibly with this kind of operation in mind. I don’t ever recall specifically asking for it as opposed to black, bright or PGMS

Whatever I certainly concur with Graham et al that as supplied none of it is really suitable for use for other than the most basic of shafting if it has to go in any kind of a bearing.

As said however PGMS is very close toleranced and is a pleasure to machine – of which, regretably, my ‘stash’ contains such a limited (very) supply

This is the blurb from Macreadys 1990 sixth edition

Anonymous.

. I do believe that was the term used by Uddeholm’s for ‘bright’ as opposed to ‘black’ finish tool steel. Most of our tool steel though not all came from them and it’s a term I do remember.

. I do believe that was the term used by Uddeholm’s for ‘bright’ as opposed to ‘black’ finish tool steel. Most of our tool steel though not all came from them and it’s a term I do remember.