The HobbyMat BFE 65 again

The HobbyMat BFE 65 again

Home › Forums › Beginners questions › The HobbyMat BFE 65 again

- This topic has 25 replies, 8 voices, and was last updated 18 July 2010 at 23:40 by

Steve Garnett.

-

AuthorPosts

-

12 July 2010 at 05:38 #53315

Sam Stones

Participant@samstones42903Hello again, especially those of you who `know’ this machine.In passing, I’m proud to say that I’ve managed to produce some tiny clock parts on the HobbyMat lathe. The smallest is little bigger than a grain of rice but less complicated in a genetic sense, if you get my drift.Before I introduce the main problem, I need to pass on the following comments :-

This morning, once the sun in Melbourne was warming up the garage, I decided to venture into the realms of milling on the BFE 65. Full of optimism, I discovered that the optical illusion (through my reading glasses) was not an illusion after all. You know the occasion when instinctively, you figure something is wrong but can’t think what. Anyway, I was about to cheat a little by using the four-way tool post to hold a square brass bar as opposed to using the HobbyMat vice which was not the most precise and needed a good clean to boot.

While setting up ready to reduce the brass in thickness using the mill, I looked more closely at the top slide, the one which has featured in a previous thread posting. I had also planned to machine a couple of angled faces via this slide. The rotary bracket was set to zero as it should be, but something was out. By sighting the top-slide with the body of the machine, I could see that the slide was skewed. Getting to the point, my dial-indicator showed that when the slide was set parallel to the machine bed, the deeply scribed marker was out by more than 1 deg !!!

I had planned to cut a 2 deg taper on a clock arbor (without thinking about any possible error). Glad I didn’t try. I also remembered that accurate (in this case conical) tapers should be set up using a dial indicator over a measure length.

With this sorted, I was soon relaxing again and merrily into milling the brass bar. Suddenly, the milling head motor stopped. I hit the STOP button, thinking it had tripped due to possible over-heating (I understand that this machine has not been used for some considerable time).

The motor was quite cool. I tried the START button again, but was greeted with a groan at mains frequency, and no rpm.

“Dear me!” I said to myself. Actually, the words were a bit stronger. “The capacitor on the motor has burnt out!”, hoping it wasn’t a winding that had gone.

So I need your help please. I have a multi-meter so, to check for things like coil failure, should I be measuring coil resistance at the main terminals? There’s a simple circuit diagram inside the terminal box on the motor which shows how five terminals are connected. What values should I expect? Would the capacitor be open circuit or a dead short?Any help you can give me would be most useful.Thanking you in advance.12 July 2010 at 05:38 #5114Sam Stones

Participant@samstones42903A burnt out something or other

12 July 2010 at 10:57 #53327John Olsen

Participant@johnolsen79199Cpacitors should measure open circuit, although witb an analog meter you can often see a kick of the needle when first connected to the meter, as the capacitor charges up.Windings should show continuity end to end. You are not very likely to be able to detect any shorted turns with a meter. The normal resistance will tend to be fairly low, a few ohms sometimes, and any change due to shorted turns is minimal. However a sudden stop while running sounds more like either a winding has gone open, or the capacitor has gone short. I suppose a winding could have gone down to ground but you would expect a fuse to go then.Usually shorted turns in the motor would be accompanied by heat, smoke, and smell. The motor would often still run, albeit poorly.Some motors kindly provide a one time thermal overload buried in the winding, which stops it setting fire to things but of course is not designed to be replaced.regardsJohn12 July 2010 at 11:11 #53328Steve Garnett

Participant@stevegarnett62550Posted by Sam Stones on 12/07/2010 05:38:45:The motor was quite cool. I tried the START button again, but was greeted with a groan at mains frequency, and no rpm.

I doubt if it’s electrical at all – the Hobbymat mills are generally fitted with nylon gears, and these have a reputation for slipping on their bushes, and locking the drive train. According to Tony on the Lathes site, just waggling the controls and jiggling the shaft backwards and forwards again is generally enough to free them. The general advice is to take the covers off and locktite the gears to the bushes – then it doesn’t happen any more. This gear issue is one of the things that put me right off getting the milling attachment for the Hobbymat at all, in fact…As for the cross-slide angular calibration, I’d say that it’s no worse than any other small lathe with a similar arrangement. The small steps are 2 degrees, and a simple calculation will reveal that even if you get the setting 1/10 of a degree out, you will end up with several thou error over the cross-slide travel. So if you want to set it anything like accurately then you pretty much have to clock it – just as you would with any other lathe.12 July 2010 at 11:21 #53330john swift 1

Participant@johnswift1Hi Sam ,I don’t have any machines with a single phase motor , so i can’t give you exact values to measure , but I would expect the main winding to be about 10 ohmson motors without a centrifugal switch the second winding to be around the same resistancewith a centrifugal switch about 20 ohms or sowith a multimeter on the high resistance range the capacitor should be shown as a low resistance at first , then climb to tens of meg ohm as the capacitor chargesto test for the odd shorted turn you will need some thing like the ring tester as insilicon chip magazine a few years ago.more expensive multimeters will measure the capacitanceunless the green’s have stopped the sale of all tungsten gls bulbs in your part of the worldyou could try connecting a 15W or 25W GLS bulb in series with the capacitorI would expect a low wattage bulb to light , but not a full brightnessthat way you can test it’s not short circuit at mains voltages ( it may be OK at 9v from a multimeter)without the circuit diagram i can not be more preciseIf you need more help send me the circuit diagram and a hint as to what test equipment are using and I’ll see what else I can doJohn Swift13 July 2010 at 22:27 #53368Sam Stones

Participant@samstones42903Thank you – John O, Steve, and John S. Your combined advice is much appreciated, and I trust will be of help to others too.

Further investigations of the BFE 65 reveal the following :-

To confirm that twisting the quill by hand is getting through to the motor (it felt as if it was), I removed the fan cowl. I can see the motor turning (forwards or backwards), while twisting the quill in any gear . This, I have presumed, rules out the gearbox, but such a simple test was well worth investigating. Thanks Steve. I also took a risk and tried a quick spin of the quill by hand while stabbing the START button. Nothing!

Other than pressing the START button a few more times, I haven’t carried out any other tests, choosing to continue using the lathe for some very basic milling and then filing parts to shape. Tiny clock parts in brass are my number one priority.

However, the `growl’ response which I mentioned is emanating from the motor, and for what it’s worth is quite low in volume. What I don’t understand is the random `pulsing’ I can hear coming from behind the START/STOP panel when I hold the START button in for a few seconds. Also, why doesn’t the starter switch latch anyway? Does latching only take effect from the motor current? Sorry, the only circuit diagram I have seen is on a label inside the lid of the terminal box. If this is of any use, I’ll photograph it and add it to my postings.

Is the above sufficient for a remote diagnosis? I welcome any comments.

By the way Steve, I’m inclined to follow your choice regarding plastics. Although I’ve been in the plastics industry since 1950, I would shy away from buying a machine with plastic gears, especially when the demand could include severe shock loading. Although not exclusive, there’s a particular weakness which dogs the plastics industry in almost any form (FRP to a lesser degree). It’s called notch sensitivity, a predominant phenomenon emanating from toolrooms producing injection moulds. Additionally, there’s ESC (environmental stress cracking). Now perhaps I’ve opened another `tin-of-worms’?

Thanks again,

Sam

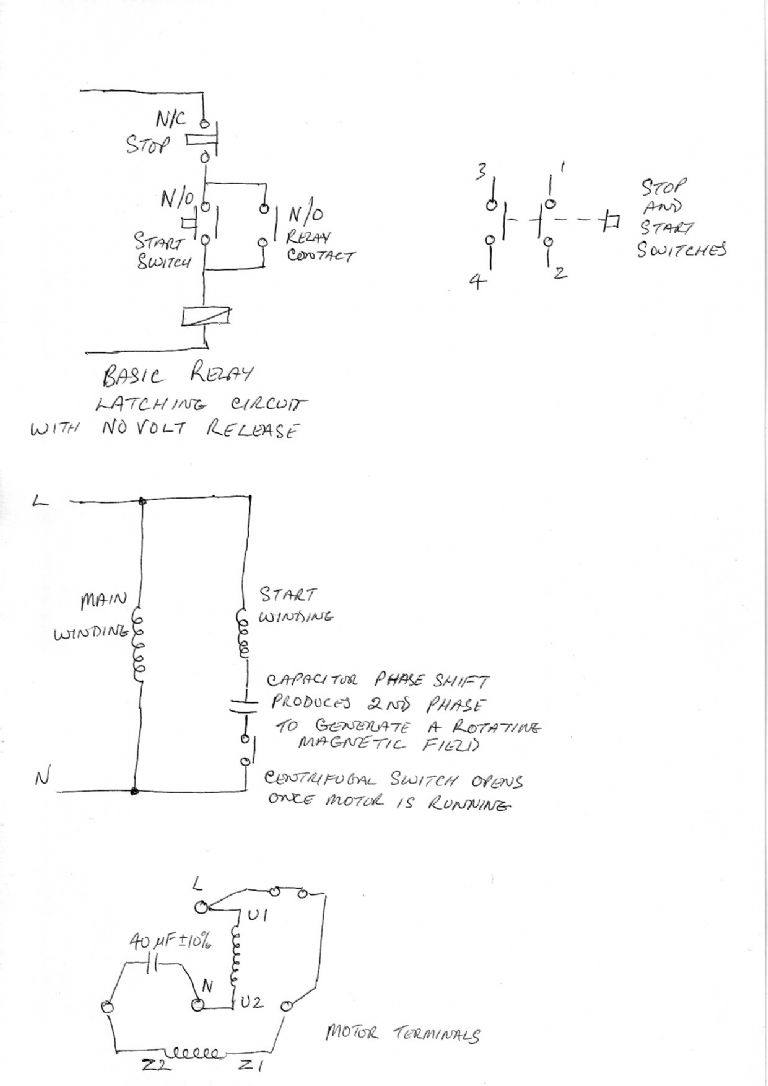

14 July 2010 at 00:07 #53374john swift 1

Participant@johnswift1Hi Sam ,tomorrow i’ll post a few simple diagrams for the start stop circuits an motor reverse circuitsIf you post the circuit diagram you have i’ll adapt one for your machinethe non latching of the start switch is a clueonce you have proved the motor is not passing an abnormal currentyou need to take a closer look at the switchesthe start switch should latch on without the motor connectedJohn Swift14 July 2010 at 04:06 #53378Sam Stones

Participant@samstones42903Hi John,

Thanks for your very prompt reply. Although the titles may not match my text, here are a few notes about each picture :-

5511—Terminal-block

The blue and brown wires (bottom right of picture) come from the capacitor. The brown wire is connected to U1, the blue wire is connected to Z1.

(See 5516—Terminal-connection-diagram)

The blue and brown wires (bottom left of picture) come from the bottom of the circuit breaker.

The striped leads disappear into the motor.

5512—Capacitor-detail

Although not the best image, the capacitor has values of 40mF/320V printed on the side.

Is the case simply earthed for safety reasons via the clamp?

5513—START-STOP-&-Circuit-breaker

(& 5514, 5515)

The mains and earth, enter the circuit via the white 3way terminal block (in the middle of 5513).

The top switch is behind the START button. Presumably N.O. (Normally Open)

The lower switch above the white 3way terminal block is behind the STOP button. Presumably N.C. (Normally Closed)

The bottom (green/blue) block is obviously the starter solenoid. Although unclear in the photograph, the black wire at the rear of the shot, loops top to bottom terminals of the solenoid block.

At the very top, there’s a black circular gadget with three terminals and a preset (locked) grub screw. Not sure what this does, but presume it’s in the solenoid coil circuit and forms part of the latching and perhaps thermal overload?

Two leads (brown and blue) from the underside of the contact breaker are connected to the terminal block. Blue to U1 and brown to U2. Refer to 5511

I now realise that the two circuit diagrams inside the cover are simply for motor direction. However, neither diagram seems to match the actual layout. I can’t see a need for a milling machine to run backwards.

Sorry about depth of field. I can take better images if needed.

Thanks a million.

Sam

14 July 2010 at 04:42 #53379Sam Stones

Participant@samstones42903Hi John,Immediately after returning everything to its place, I plugged in and pressed the START button.THE MOTOR SPUN FOR A COUPLE OF TURNS AND THEN STOPPED!I tried once more, and the quill turned slightly.Does this help?Regards,SamPS Would this be better sorted by direct email?14 July 2010 at 05:52 #53380Sam Stones

Participant@samstones42903I omitted to say that the pulsating growl when holding down the START button, is coming from behind the START/STOP button. Probably from the circuit breaker solenoid.

14 July 2010 at 10:18 #53386joegib

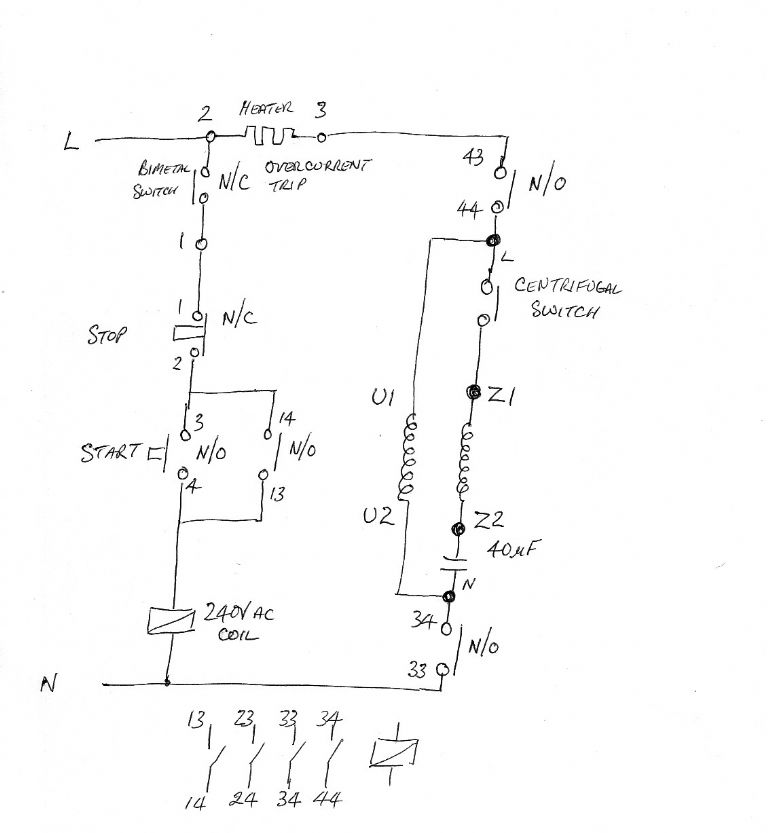

Participant@joegibI should say this is described as the lathe motor circuit/control system but since the mill motor set-up is not separately shown, I believe the latter is exactly the same electrically.The full manual is available from the Prazi Yahoo newsgroup here:in the 'Files' section –> 'BF400 Manual'. Unfortunately, to get access you need to join the group and that can be a problem. The administration of the group is unreliable so it may take a week or two for the membership to be registered. It can take that long for a post to appear!. But it's worth trying so as to get access to useful material.I'll leave it to the electroheads to comment on the implications. Joe

JoeEdited By joegib on 14/07/2010 10:23:14

Edited By joegib on 14/07/2010 10:24:30

Edited By joegib on 14/07/2010 10:25:55

Edited By Katy Purvis on 01/06/2015 11:49:53

14 July 2010 at 11:41 #53388Sam Stones

Participant@samstones42903Many thanks Joe.One of your attachments wouldn’t show, but the Prazi circuit diagram will be very useful.From this diagram, and the symptoms I’m beginning to think that the `protective’ switch may have something to do with the start/running of the motor, and preventing latching. I’ll wait until the `electroheads’ as you call them, have read my more recent posts, and have had a chance to look at yours.In passing, and for the benefit of the others contributing to this thread, I have to say that the growl I mentioned is a fairly quiet mains frequency groan (hum). The pulsing I’ve mentioned is just audible above the level of the 50Hz hum, and seems to affect, (dare I say) modulate it.Thanks again,SamEdited By Sam Stones on 14/07/2010 11:44:15

Edited By Sam Stones on 14/07/2010 11:52:35

15 July 2010 at 03:01 #53405john swift 1

Participant@johnswift1Hi Sam,I have scanned a few quick diagrams I hope will helpIf the contactor operates when you push the start buttonthe overload cutout must be closeda fault in the connections to the contactor terminals 13 & 14or the contact is self would stop it latching onwith the mains disconnected you can push down on the top of thecontactor and check you have a low resistance when the contacts makeand across terminals 2 &3 of the overload unit – the heater coil should be low resistanceat the motor terminals check the continuity of the windings and the centrifugal switchIf your meter can check the capacitor is 40 uFyou might end up substituting it with a new one to prove if it ok or notwith the mains on the full mains should be across the motor winding U1 to U215 July 2010 at 09:44 #53409john swift 1

Participant@johnswift115 July 2010 at 11:16 #53411Jim Whetren

Participant@jimwhetren72358Hello Sam,I don’t want to go off on a tangent to what has already been said, but I would like to make an observation.I have both a Hobbymat mill and a Prazimat lathe from the same East German manufacturer which have some similarities, for instance the large aluminium hand wheels are identical.The mill motor looks to be a smaller version of the lathe motor. To get to the point, I had a fail to start buzz with my lathe which turned out to be the centrifugal start switch. I found that one of the contacts had disappeared, leaving one contact point and a hole in the end of a contact spring, causing the intermittent contact.I managed to find some salvaged contacts and removed the contact point and riveted in place. The lathe has been working ever since.Sorry for the ramble, but it was just a thought.regardsJim15 July 2010 at 12:26 #53415Sam Stones

Participant@samstones42903Gentlemen,

Thank you so much for all your advice wrt the BFE 65 mill. Those initials are getting to me, and I’ve wondered if they have a secret meaning. Any ideas?

Anyway, I really appreciate getting this sort of help from you people, especially the circuit diagrams and the effort you have all put into solving my problem. Had this been my machine (its only on loan), perhaps I would have pulled it apart without hesitation. But since it isn’t, and the failure happened while I was at the helm so-to-speak, I feel obliged to get it fixed as professionally as possible.

I have a couple of pieces of news. A good friend has offered to take a closer look at the electrics, and to apply various electrical tests. My guess is that he’ll have the right gear. He also pointed out that since the machine has stood around for a considerable time (information I gathered about the machine a few days ago), and has only been used a couple of times in that period, there is a strong likelihood that the capacitor has deteriorated.

There are a couple of snags to this offer. For various other reasons, we will carry out the tests at his place. Also, not being as fit and tough as I used to be, lifting is becoming a “NO NO!” (That’s the wife from the kitchen). This morning I stood pondered the problem of how to get the BFE 65 mill into the back of our car without any serious lifting. Of necessity the whole unit needed to be given a straight lift upwards to extract the vertical column from the bracket attached to the back of the lathe. Years ago, as a toolmaker, I was obliged to carry out this simple (clean & jerk) movement, while splitting plastics moulds apart on the bench. Using the quill to jack the whole caboodle from its resting place, and somehow progressively insert blocks underneath turned out to be futile.

However, I decided to avoid a strained back, and split the head at the swivel point, bearing in mind that those two inaccessible `T’ nuts will drop down into the wrong place when I reassemble. I’d done this `trick’ before on my Jack Jones, so I tried again and it worked a breeze. The gearbox and motor are not that heavy, so they’re sitting in the back of the car ready for tomorrow’s trip. Those circuit diagrams should help a lot too.

Here’s hoping for a good (final) posting and an end to this thread.

Best regards,

Sam

15 July 2010 at 12:34 #53416 Nicholas FarrParticipant@nicholasfarr14254Hi, the circuit diagram that Joe has posted for his Prazi is exactly the same as printed in the user manual that I have for the Hobbymat BFE 65.Regards Nick15 July 2010 at 13:31 #53419

Nicholas FarrParticipant@nicholasfarr14254Hi, the circuit diagram that Joe has posted for his Prazi is exactly the same as printed in the user manual that I have for the Hobbymat BFE 65.Regards Nick15 July 2010 at 13:31 #53419 Nicholas FarrParticipant@nicholasfarr14254Hi again, the black circular gadgit that you mention is e1 on Joe’s diagram and is a thermal over load that takes at least 10 seconds to reset acording to the user manual instructions.regards Nick.15 July 2010 at 15:10 #53422

Nicholas FarrParticipant@nicholasfarr14254Hi again, the black circular gadgit that you mention is e1 on Joe’s diagram and is a thermal over load that takes at least 10 seconds to reset acording to the user manual instructions.regards Nick.15 July 2010 at 15:10 #53422joegib

Participant@joegibHi Sam,

Just a few final remarks:

1. Your method of disassembly is fine — for various reasons I’ve had my head off the machine several times and this is the way I always do it, leaving the column in situ. When you come to re-install it I suggest you place a couple of wooden blocks across the lathe bed, (after removing the gear and quill drive levers temporarily), place the head horizontally with casing resting on the blocks (say, motor to left, spindle to right and mounting ring at the back, of course), bring the head mounting block down the column, simply align the block spigot with the head mounting ring and push the head backwards onto the spigot. I haven’t done this job for several years but I don’t remember any special difficulty in aligning the the captive T-nuts with the Allen securing bolts. This assumes you have access to the back of the machine. If not, bear in mind that you can loosen the Allen screws in the column base casting and swing the whole assembly round to get access to the bolt holes.. In this case you must use some method to keep the head mounted on the spigot temporarily e.g strap the head to the column with holdfasts .

2. If for any reason your friend decides to separate the motor from the head, he should beware of one oddity with these machines. Normally, we all expect the key to be firmly fitted to a motor drive shaft. Not necessarily so with this machine! The key was quite loose and, oddly, extended maybe an 1/8th of an inch beyond the end of the motor shaft. Moreover, there was a fine pin through one end of the key that fitted in a corresponding hole drilled in the key seating. Maybe this is designed to stop the key dropping down into the gearbox when installing the motor vertically. Even so, it is still possible for the key to drop into the head innards if knocked on assembly so (a) the motor shaft and key should be degreased and secured using Loctite and (b) the motor should be mounted into the head horizontally. None of this may be relevant in your case if motor separation is not required.Good luckJoeEdited By joegib on 15/07/2010 15:13:00

16 July 2010 at 00:09 #53436Sam Stones

Participant@samstones42903You beaudie, as they say down here in OZ.

Thanks again for all your information, I’ll get back with a report shortly.

Meanwhile, I’ve opened a photo album for the skeleton clock, starting with a HLR (hidden line removal) image from my KeyCreator file via Photoshop CS3.

Finishing this clock is my prime target.

Thanks to all.

Sam

17 July 2010 at 00:49 #53473Sam Stones

Participant@samstones42903Good day Gentlemen,

In my friend’s workshop yesterday, tests of the electrical component of the BFE 65 mill revealed several issues and anomalies. Before I continue however, I have to thank again, those ME members who, through this thread, have offered their comments. In return, I trust that the following details may be of help to others with similar experiences.

A couple of theoretical (possibly trivial) aspects are noted, such as :-

a) The circuit diagram show the capacitor’s value as 8mf/460V~ while the actual capacitor is rated at 40mf/320V~. I’m told that a larger capacitor may improve the motor torque a little.

b) The circuit diagram shows the motor rated at 220V which immediately drew suspicion from my friend. Whenever I’ve measured our domestic supply, it has been a healthy 250V. However, the tiny motor indicator plate displays 240V.

The 40mf capacitor passed every electrical test, but started to heat up when the motor was placed directly across the mains for a few seconds, (ie bypassing the START/STOP contact breaker circuit).

The motor’s insulation to earth via a high voltage test meter got an “OK!” when it showed a very high resistance.

Using a current meter around single (input) wires in the motor terminal box, motor current on the two windings measured about 7amps and 5amps. We didn’t try to identify which winding was which.

When the motor was removed from the gear box, the shaft could be spun by hand with no mechanical resistance. In fact, it turned very smoothly. Thanks for the warning about the loose key Joe! As you might expect, Murphy placed it face down, but we were ready.

Applying mains as before, we could also hear a centrifugal switch responding to motor rpm, dropping out as it approached running speed and then back in again as it stopped. This latter issue appears to conflict with the circuit diagram which doesn’t show this switch. The presence of amperage on both windings while the motor was running suggests that the centrifugal switch is ineffectual, or for some other reason, the capacitor remains in circuit.Was this why it began to heat up?We didn’t get around to John Swift’s suggestion of testing the solenoid `latching’ while the motor was disconnected. However, I tried it myself this morning.More disappointment!It wouldn’t latch and instead, I could hear the pulsing (mains frequency) groan I mentioned before.Prognosis –

1. Probable shorted-turns in the motor.

2. An unexplained fault in the starter circuit.

I was expecting closure on this thread. Murphy should take a holiday.

Thanks again for all your comments and help.

Sam

17 July 2010 at 09:58 #53480joegib

Participant@joegibHi Sam,

Sorry to hear you weren’t able to achieve a quick fix yet. Hopefully, our electrical specialists will be able help further (I hasten to say my earlier reference to electroheads wasn’t meant to be disrespectful). In the meantime I’ll post a few further comments about re-assembly and other matters.

1. My motor’s capacitor is also 40μF so it’s standard albeit it doesn’t match the circuit diagram.

2. From your description it doesn’t look as though the motor needs replacement. For the record, however, I’ll just say that this is another oddball feature about the machine. According to the motor plate the motor has an IEC 63 frame which would normally correspond to a shaft diameter of 11mm. However, this motor actually has a shaft diameter of 14mm which matches an IEC 71 frame.

3. On reflection I was a bit vague in my description of the re-assembly procedure. I’d forgotten that the Hobbymat lathe only has a fairly narrow D-section shear so blocks placed on this won’t be stable enough. I’d recommend, therefore, that you make a little platform out of scrap plywood/MDF/battens/blockwood to straddle the lathe bed and provide a solid base for the head. If you remove the lathe topslide the platform only needs to be high enough to clear the crosslide table.

4. As regards the problem of the T-nuts, I’ve remembered how I handled this. Place the head on the platform with the mounting ring uppermost (motor to left, spindle to right). Place the T-nuts in the 3 and 9 o’clock positions. Put a couple of solid gobbets of grease behind the T-nuts (to provide some stickablity when the ring is turned into the vertical). Screw a couple of short lengths of suitable studding into the T-nuts (if you don’t have studding, improvise some by cutting the heads off suitable metric bolts). Turn the head over on the platform so the ring/T-nuts/studding face the column. With your index/forefingers clasping the studding each side of the ring, and using the heels of your hands (or chest/stomach!), slide the head towards the column mounting spigot. Push it home using your fingers to guide the studding through the capscrew holes on the mounting block. With a capscrew in one hand close to the hole, gently unscrew the studding with your other hand and as soon as it’s free, quickly stick the capscrew into the hole so it snags the T-nut hole before the latter has a chance to slide down (the grease should hold it long enough). Repeat on the other side, and it only remains to tighten up, wind the head up the column, swing it into its vertical position and you’re done.

Joe

17 July 2010 at 11:38 #53487john swift 1

Participant@johnswift1Hi Sam ,I suspect when the manual was produced another type of motor had been selected .motors up to 200 watts or so are made that have a small capacitor connected all the time as shown in the manual.the 40uF capacitor looks right for motors with a centrifugal switch as you haveif the current you measured in both windings is after the motor achieved speeddouble check the centrifugal switch does open when the motor is at speedwhile it sounds like its working the contacts may be welded closed or you havea wiring fault .as you have noticed products from europe are designed for 220v-240vsince the uk gave in to europe , sorry harmonised with , the mains voltage here isstill 230v to 250v .the figures fudged to keep the bureaucrats happy and confuse every one elseexample my thomson / sky tv box, made in france is labled 230v 50 Hzand another thomson box 220v-240v17 July 2010 at 11:59 #53489Martin W

Participant@martinwHi SamMotors aren’t really my field but I have a couple of observations/questions regarding the motor and its running or not.1. I take it that the motor runs up to speed when the mains is directly applied to it. The fact that the capacitor is getting hot indicates that the centrifugal switch is not breaking the supply to the start winding. Although you can hear it, or part of it, operating it may the contacts are not opening. Alternatively there may be a short in the wiring in/or associated with this switch. Is the switch and wiring easily accessed for inspection?2. This is where I am on shaky ground . If the centrifugal switch is not operating/opening then of course there will be current flowing in the start winding and 5 amps or so does not seem excessive for this. If this is the case then could this be causing a higher current to be flowing in the running windings of the motor

. If the centrifugal switch is not operating/opening then of course there will be current flowing in the start winding and 5 amps or so does not seem excessive for this. If this is the case then could this be causing a higher current to be flowing in the running windings of the motor  . If so then you fears re shorted turns in the winding could well be unfounded.3. I seem to recall that I had a similar fault with a latching relay switch and it was down to a failure in the connections to the latching coil winding. It was cured by replacing the switch.4. With regard to volts and measured current. This is complex area as the phase between current and voltage varies with the inductance and capacitance of the load. Capacitors cause a phase lag of voltage to current and inductors cause a phase advance of voltage to current. Therefore estimating the power being dissipated in such a circuit is not simply multiplying voltage by current.5. On the circuit diagram supplied there doesn’t appear to be a centrifugal switch in circuit with the capacitor feed to the start windings.Just a few observations that hopefully may be helpful.Cheers Martin

. If so then you fears re shorted turns in the winding could well be unfounded.3. I seem to recall that I had a similar fault with a latching relay switch and it was down to a failure in the connections to the latching coil winding. It was cured by replacing the switch.4. With regard to volts and measured current. This is complex area as the phase between current and voltage varies with the inductance and capacitance of the load. Capacitors cause a phase lag of voltage to current and inductors cause a phase advance of voltage to current. Therefore estimating the power being dissipated in such a circuit is not simply multiplying voltage by current.5. On the circuit diagram supplied there doesn’t appear to be a centrifugal switch in circuit with the capacitor feed to the start windings.Just a few observations that hopefully may be helpful.Cheers MartinEdited By Martin W on 17/07/2010 12:17:02

18 July 2010 at 07:12 #53518Sam Stones

Participant@samstones42903Thanks to you Joe, John, and Martin. As with others who have contributed to this thread, I really appreciate your comments both electrical and mechanical.

I must also apologise if I keep repeating myself. My own knowledge of electrics and electronics is relatively flimsy, and although my father was an electrician, I still rely heavily upon others like yourselves for technical support and confirmation. Conversely, my friend has a respectable background in these fields, and used various pieces of test equipment to determine the motor issues.

With mains connected directly, ie. bypassing the START/STOP solenoid etc. the motor runs up to speed. However, there is a distinct hum which concerned my friend. As I’ve mentioned before, the centrifugal switch can be heard operating, but according to the current-meter reading, there is current flowing through the capacitor.

To close a few loose ends, when I tried the solenoid START/STOP operation with the motor disconnected, it failed to latch. But it did produce the pulsating mains hum I mentioned before. So there’s a `Non-latching’ fault which needs fixing. I suspect that if the centrifugal switch has failed to open and therefore failing to disconnect the capacitor during the running mode, the protection circuit may have suffered.

We didn’t investigate the centrifugal switch, but this afternoon, I removed the cowl, the nylon cooling fan, and the die-cast cover over the centrifugal switch. A long brass screw passes through a bush and the motor shaft to keep the rotating parts of the switch in place. However, without a puller tool, I wasn’t prepared to try removing the bush and the rotating parts. The bush was firmly stuck to the shaft!

It wasn’t possible to see the switch contacts or the wiring Martin, although I could move the sliding part of the switch, ie. the part which is usually toggled from one position to the other and back again. The mechanical parts all appear to work freely against their respective springs.

Having reached this point, I have decided to leave things alone until I’ve spoken with the owner of the HobbyMat lathe/mill. He may choose to take this on board himself, and I need to get on with finishing the clock.

By the way, although I don’t know what the current-meter is actually called, it has large, heavily insulated jaws which open to surround and close around a single wire. I presume that it determines AC amperage by means of the induced magnetic field.

Joe – thanks for your description of how to place the T-nuts. I did it once before, but it was all lying on the bench, and the bolts were at 12 and 6 o-clock. The first one went in a treat, but I had to jiggle around for the second one. A good blob of grease will do fine, but would you believe that my tin went out the door when I got rid of my workshop? Currently, that section of the mill is now on the vertical column, and the bolts are at 3 and 9 o-clock. I expect that I’ll have to fish a little.

Given more time, I would be inclined to machine a ring of wood or similar material to fit loosely in the T-slot. This would be cut into two pieces removing the extra material where the T-nuts normally sit. Given more time, a ring made of steel could be used, suitable threaded to completely replace the T-nuts. Of course this would require unscrewing more screws to access the back of the T-slot.

Thanks again.

Sam

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Beginners questions › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

IME Watchmakers lathe

Started by:

Greensands in: Manual machine tools

- 5

- 6

-

1 July 2025 at 08:26

SillyOldDuffer

-

New member looking for help

Started by:

manfromthemist

in: Introduce Yourself – New members start here!

manfromthemist

in: Introduce Yourself – New members start here!

- 11

- 24

-

1 July 2025 at 08:19

Juddy

-

Request for a Slot to be Milled in a Shaft

Started by:

James Alford in: Help and Assistance! (Offered or Wanted)

- 7

- 13

-

1 July 2025 at 07:44

James Alford

-

M type top slide conversion??

Started by:

jimmyjaffa in: Beginners questions

- 6

- 10

-

1 July 2025 at 07:20

JasonB

JasonB

-

Twin Engineering’s heavy mill/drill quill removal

Started by:

Martin of Wick in: Manual machine tools

- 6

- 7

-

30 June 2025 at 23:33

James Frankland

-

Bearing boxes for ball race

Started by:

Paul McDonough in: Beginners questions

- 8

- 14

-

30 June 2025 at 22:43

Stuart Smith 5

-

All things Beaver Mill

1

2

…

8

9

Started by:

Robert James 3 in: Manual machine tools

- 42

- 205

-

30 June 2025 at 21:14

Mark Rand

-

2 Machine lights

Started by:

modeng2000 in: Workshop Tools and Tooling

- 2

- 5

-

30 June 2025 at 20:15

modeng2000

-

Firth Valve Gear

Started by:

Andy Stopford in: Traction engines

- 7

- 15

-

30 June 2025 at 19:58

Andy Stopford

-

Wiring up a single phase AC motor with 4 wires

Started by:

ell81 in: Beginners questions

- 6

- 8

-

30 June 2025 at 19:49

Howard Lewis

-

New (old!) member

Started by:

iansoady in: Introduce Yourself – New members start here!

- 3

- 3

-

30 June 2025 at 19:30

Howard Lewis

-

Meddings MF4 Manual

Started by:

Richard Kirkman 1 in: Help and Assistance! (Offered or Wanted)

- 9

- 17

-

30 June 2025 at 16:11

Richard Kirkman 1

-

FreeCAD v1.0 tutorials

1

2

3

Started by:

Michael Gilligan

in: CAD – Technical drawing & design

Michael Gilligan

in: CAD – Technical drawing & design

- 12

- 51

-

30 June 2025 at 15:40

Speedy Builder5

-

Boiler Design – issue 4765

1

2

…

7

8

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 178

-

30 June 2025 at 12:58

Paul Kemp

-

High strength 4mm steel?

1

2

Started by:

iansoady in: Materials

- 20

- 31

-

30 June 2025 at 10:55

JohnF

-

What Did You Do Today 2025

1

2

…

6

7

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 32

- 172

-

30 June 2025 at 07:37

Diogenes

-

cutting cams

Started by:

bricky in: Help and Assistance! (Offered or Wanted)

- 4

- 14

-

30 June 2025 at 06:54

JasonB

JasonB

-

Cookies

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 4

- 4

-

29 June 2025 at 21:42

Fulmen

Fulmen

-

Multi Cylinder Radial Engine.

Started by:

ebeneezer in: I/C Engines

- 3

- 5

-

29 June 2025 at 20:24

JasonB

JasonB

-

Clarkson MK3 t&c grinder

Started by:

Gerd Vanhaevere in: Manual machine tools

- 5

- 7

-

29 June 2025 at 19:07

noel shelley

-

Offen screw type telescopic gauge.

Started by:

Graeme Seed in: Workshop Tools and Tooling

- 3

- 7

-

29 June 2025 at 18:41

bernard towers

-

Tell ‘Em Straight! (Anti-virus sellers)

Started by:

Nigel Graham 2 in: The Tea Room

- 3

- 3

-

29 June 2025 at 13:35

Andrew Crow

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 4

-

29 June 2025 at 10:05

JasonB

JasonB

-

My experiences with an ELS lathe

Started by:

David Senior in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 9

- 17

-

29 June 2025 at 08:59

Diogenes

-

TurboCAD Snaps and Dimensioning?

1

2

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 8

- 36

-

28 June 2025 at 18:30

Nigel Graham 2

-

IME Watchmakers lathe

-

Latest Issue

Newsletter Sign-up

Latest Replies

- IME Watchmakers lathe

- New member looking for help

- Request for a Slot to be Milled in a Shaft

- M type top slide conversion??

- Twin Engineering’s heavy mill/drill quill removal

- Bearing boxes for ball race

- All things Beaver Mill

- 2 Machine lights

- Firth Valve Gear

- Wiring up a single phase AC motor with 4 wires

. If the centrifugal switch is not operating/opening then of course there will be current flowing in the start winding and 5 amps or so does not seem excessive for this. If this is the case then could this be causing a higher current to be flowing in the running windings of the motor

. If the centrifugal switch is not operating/opening then of course there will be current flowing in the start winding and 5 amps or so does not seem excessive for this. If this is the case then could this be causing a higher current to be flowing in the running windings of the motor  . If so then you fears re shorted turns in the winding could well be unfounded.

. If so then you fears re shorted turns in the winding could well be unfounded.