When I joined this illustrious Forum, I mentioned that eventually I would be dusting off one or two of those projects that, err, aren't quite done yet, most of us have one or two or more. One such is a 9 cylinder spark ignition radial drawn up by Lee Hodgson of Ageless Engines, but ever since I bought the drawings in the last years of the last century, and every time that I rediscover the collection of pieces, materials and tooling, I have become somewhat older, the Management indoors refers to it as the Ageing Engine and suggests that by taking a 'selfie' alongside each picture, progress might have been quicker!!

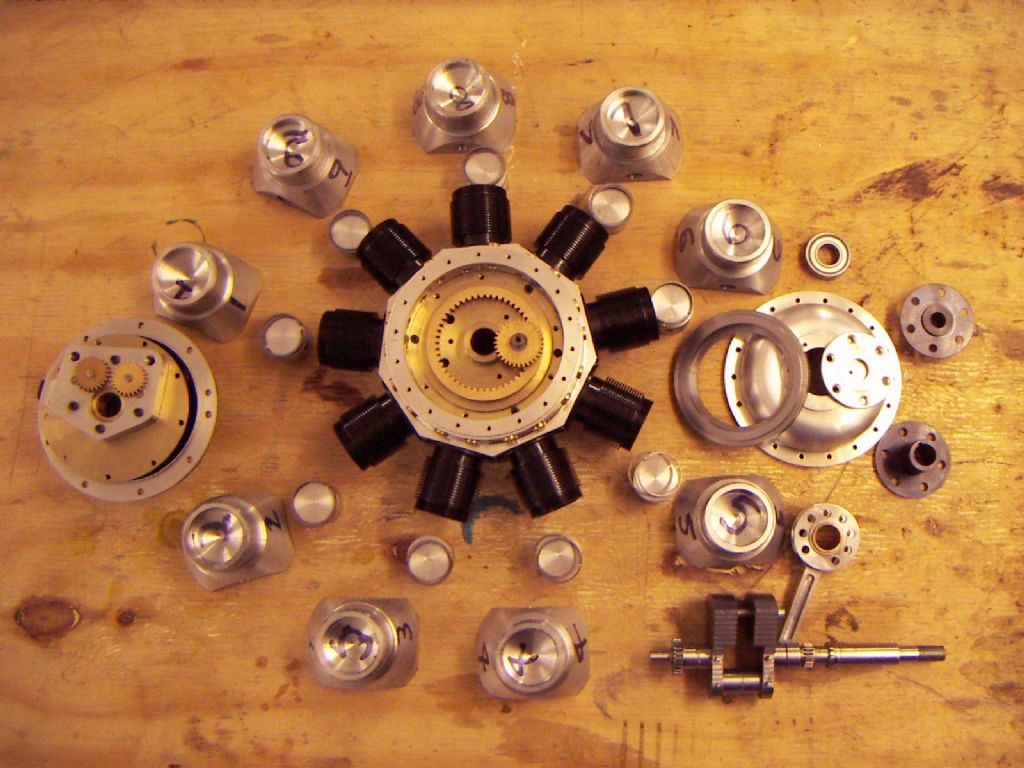

This was the state of play some when in 2004

I had made the cylinders,pistons and rings; front cover, crank, most of the gears, a functioning oil pump, front and rear bearings, a 'practice set-up ' master rod and had done most of the work on the crankcase and made the fixture to machine the heads.

The years up to 2010 saw little done and apart from the basic shaping, threading and finning of the cylinder heads on the fixture that I had made in 2004, not much progress had been made. The only other advance was the hot caustic blacking of the cylinders, which was quite successful, though I think that the kit which I used is not available now. The holes for the cylinder studs had been drilled but still needed tapping along with most of the others in the crankcase.

And then life, and all that goes with it got in the way, as it does with most of us, suffice to say that not a lot happened in 8 years ………..until this week, when after making a couple of tapping jigs, buckets of cutting fluid and several fresh 4-40 UNC taps, I spent more than a couple of hours threading the front and rear bearing shoulders and the cylinder stud holes,all 72 of them. And so the crankcase, after about 15 years since first bolting a slab onto the faceplate, is finally finished!

Now that the ball is rolling, and the clock is definitely ticking, I'd better do something about the cylinder heads!

Trevor

Chris Evans 6.