Hi Evan,

I will try to answer the questions from your last two posts partially copied below.

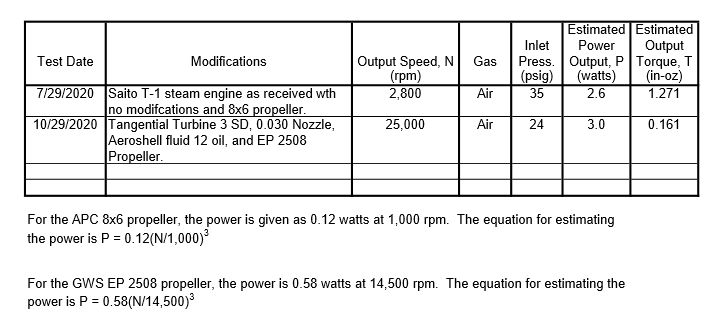

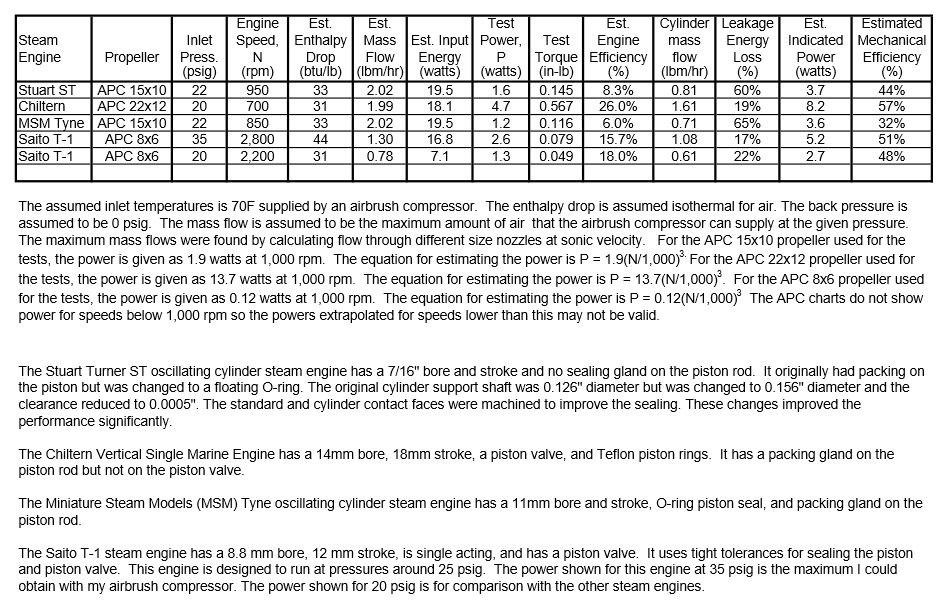

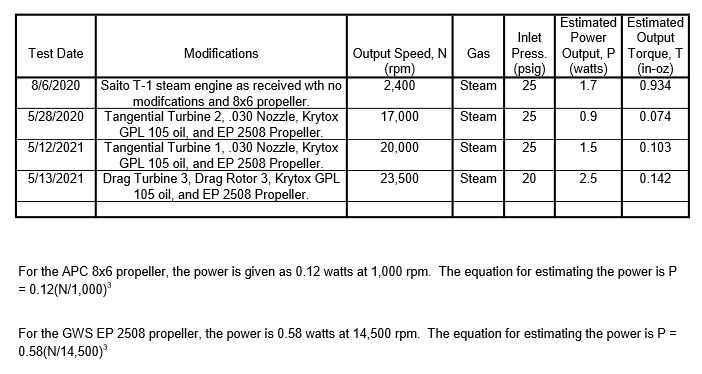

I was interested in a comment in the thread that the turbine jets go "sonic" at 25 psi. It is important to show the pressure as absolute (psia) or gage (psig) and the gas (steam, air, etc.). The critical pressure ratios are 0.528 for air, 0.547 for superheated steam, and 0.577 for saturated steam. For air with the exit pressure being atmospheric (14.7 psia), the inlet pressure would have to be 14.7/0.577= 25.5 psia = 10.8 psig to go sonic.

Are you able to explain in simple terms why the Hero reactive turbine is so much less efficient than other turbines which are so efficient that they are used in nearly all operating stations? The problem with the Hero turbine is the very high speed (approximately twice the speed of an impulse turbine) required to obtain reasonable efficiencies

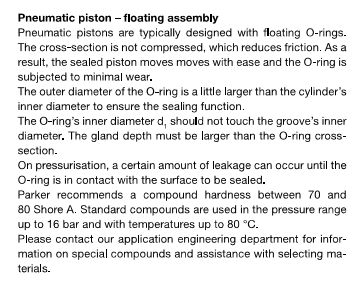

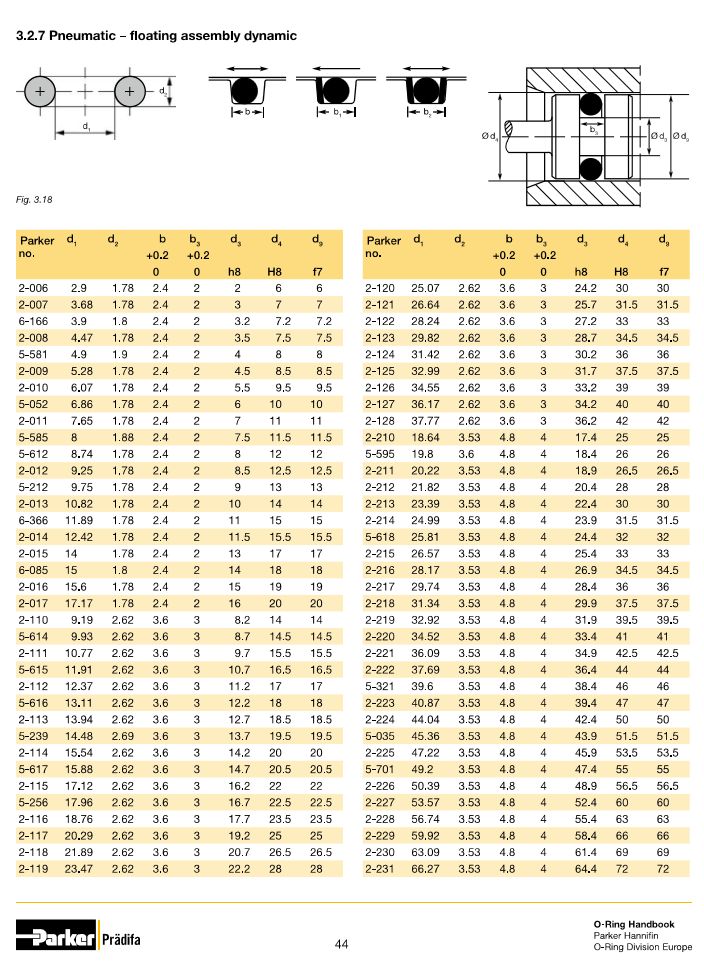

For simplicity I am thinking of using O-rings for piston seals. To keep friction down I understand they would be fitted loosely. I imaging they should only just touch the cylinder walls with no perceptible compression. Is that right? I tried both floating and light compression of the O-rings. The floating type as described in the follwoing link worked best. Floating O-ring

I am using pistons as valves instead of the usual flat plate so that I can do it easily on the lathe. Can I use rings on these valve pistons too or will they get torn up by the ports? Both of my steam engines that use piston valves rely on a close fit and have very low leakage. Whatever gain you get with seals will probably be offset by the extra friction.

Our hardware shop says they can get two kinds of O-ring: Nitrile eg N70 which are recommended for temperatures up to 90 degrees C, and red Vitron up to 200C. I assume I would need the Vitron type. I used the Viton.

My radiator man found that it had 5 O-rings from China that had gone soft and gummy, completely flattened. But why did it pass pressure tests? If the pressure is enough to move the O-ring, it will press against the sealing surfaces and stop the leakage.

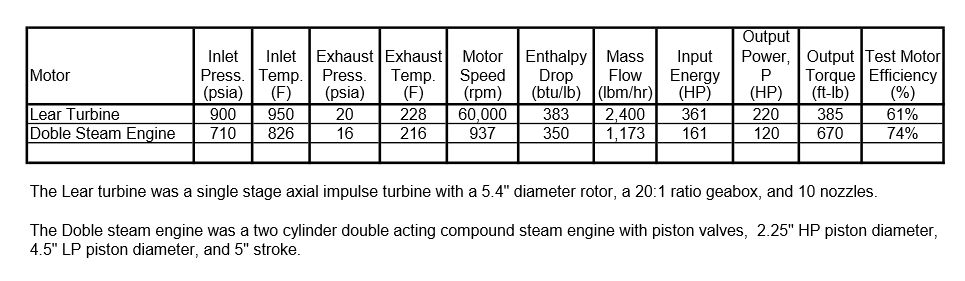

The engineering Co A&G Price Foundry I was talking about had a license to male Doble steam buses for Auckland City. Would they have been turbines? I think the only steam buses tried in California were the Lear turbine. There were other competitors and might have been tried.

Edited By Turbine Guy on 18/11/2020 14:30:33

Turbine Guy.