TG,

That answers my question.

Regarding efficiency, I think you have a couple things going on that may be throwing you a curve.

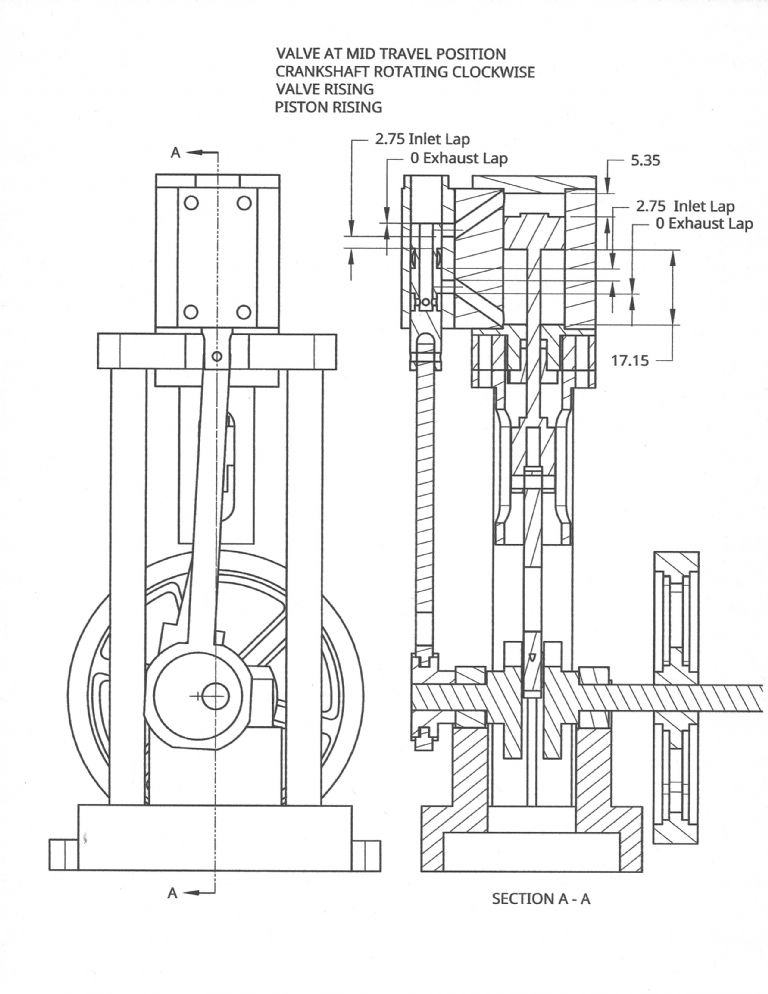

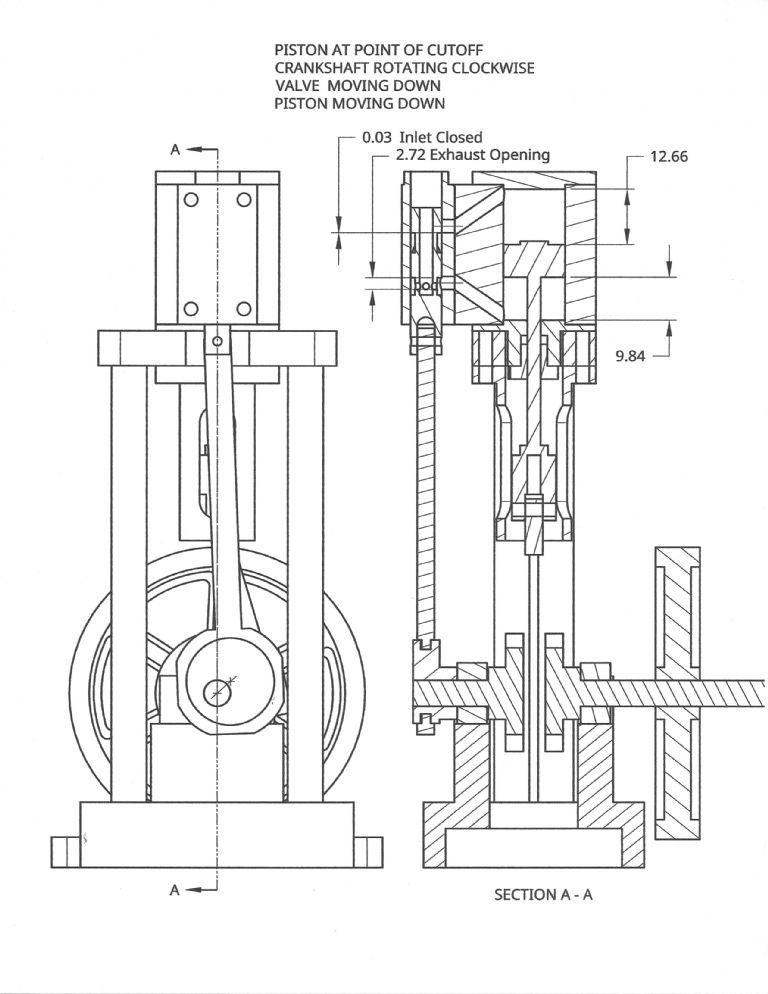

First, there is a big difference between D&S steam and compressed air – steam has roughly 8 times the enthalpy of compressed air at the same pressure & temperature. Steam is not an ideal gas, and steam engines are designed to take advantage of the isentropic enthalpy drop and the expansion characteristics of steam. The valve timing for steam, for example, is not what would be the most efficient for compressed air. A steam engine running on air will not be as efficient as if it were running on steam.

Second are the leakage paths you have already mentioned. Design clearances take into account thermal expansion at operating temperature, and what may be a significant leak at room temp, will not be at designed operating temperature.

Was your clearance volume in in^3 or cm^3? Based on your 14mm bore by 18mm stroke, I calculated the swept volume as 2.77 cm^3. The optimum clearance volume is typically around 10% of the total volume, so if your clearance volume is in cm^3, then it's in the ball park.

I find your progress quite interesting – please keep us posted………

Tim

Edited By Tim Taylor 2 on 20/01/2019 22:13:48

Turbine Guy.