Gentlemen,

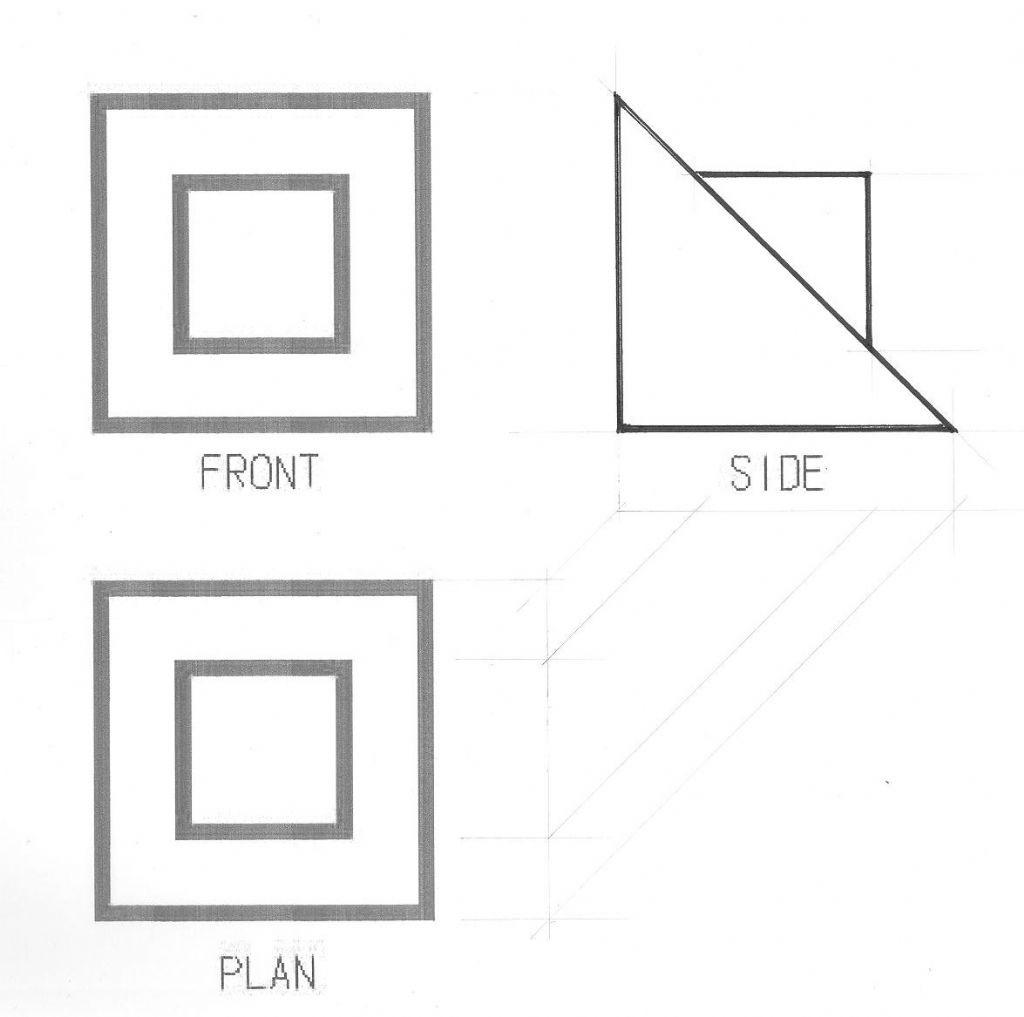

With the cat out of the bag, Nick has shown one of the solutions and has clearly used 3rd angle projection.

Or has he?

Don’t take this personally Nick, because (I hope) I’m trying to bring attention to an important part of Terry’s original idea.

If it were (all) 3rd angle dangle, sorry projection, shouldn’t the small square of my original PLAN view be dotted? And where should the PLAN view be positioned to avoid this? In the words of `Top Gear’ James May “Oh cock!”

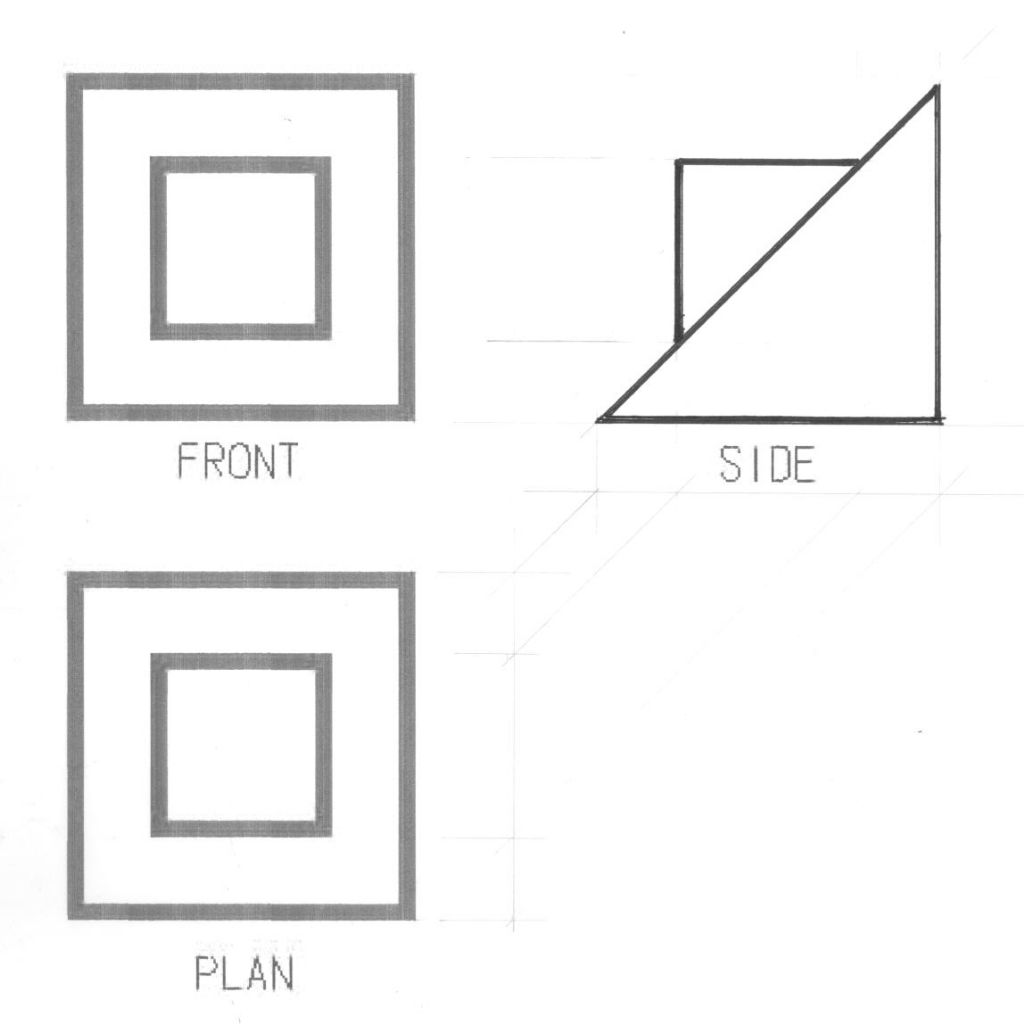

While, from a young age, I learned to draw in 1st angle (as a Pomme – English projection comes naturally), I have become `tolerant’ to 3rd angle projection, a method better suited to drawing very long objects such as aircraft and ships.

However, I still maintain (and have taught for many years) that 1st angle is by far the better system for moulds of the injection type. In the plastics industry (especially this country), countless drawings are constructed in 3rd angle, an Australian industry `standard’. Sadly, the views and sections end up in all sorts of weird positions, contradicting the basic rules of 3rd angle, and showing little to no resemblance of how the mould is positioned in the moulding machine. The primary desire appears to be to use up as much space on one drawing, with part of the mould sitting sideways on the bench.

The primary desire appears to be to use up as much space on one drawing, with part of the mould sitting sideways on the bench.

Then along came CAD.

This was the door which opened us up to the wonders of 3D solid modelling but, I believe, caught a lot on the hop. To keep pace with a changing world, they had to learn CAD, and with most commercial software, months of training was often required (and still does).

Personally, other than the cost, I found 3D CAD a delight, and only look(ed) upon 2D as a means of initial construction or when conveying information when my client requested dimensioned (paper) drawings via the plotter.

Perhaps we should wait a little longer for someone to show us other alternative solutions to what has become known here as Sam’s test!?

Best regards to all who sail in her,

Sam

By the way, is a nurd, (nerd, nurd), Imperial or Metric?

Edited By Sam Stones on 21/04/2011 01:07:36

Steve Garnett.

The primary desire appears to be to use up as much space on one drawing, with part of the mould sitting sideways on the bench.

The primary desire appears to be to use up as much space on one drawing, with part of the mould sitting sideways on the bench.