Been busy developing my SolidEdge CAD skills by tackling various parts and assemblies. After replicating Jason's current engine in cyberspace, I've left him to build a real one. Don't want to get into a race because I reckon he shapes metal about twenty times faster than me!

Thought I try something a bit different: with forum help can I design an engine that can be 3D printed and run on compressed air. There are interesting advantages and disadvantages.

Advantages:

- Plastic can be printed in almost any shape with internal cavities and passages that cannot be made with a lathe, mill or even casting. (3D printing is like casting on steroids!) It makes previously impossible constructions possible.

- All the skill is in the CAD design; the parts are made by machine.

Disadvantages:

- Accuracy is limited compared with metal bashing; about 0.1mm on my hobby printer, and that's optimistic!

- Finish tends to be poor, with ridges and blobs.

- Limited to low temperatures – less than 100C.

- Plastic's not very strong: the design might have to pay much more attention to stresses and strains than an equivalent metal engine. There's a strong incentive to reduce cost and print time by leaving holes in a thin structure wherever possible

- It's at the limit of my understanding

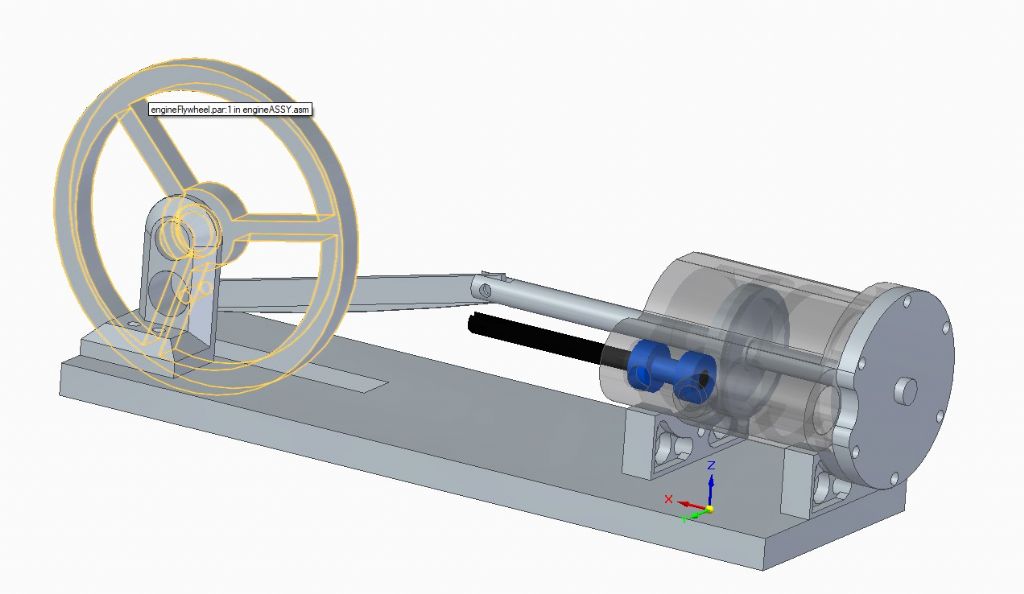

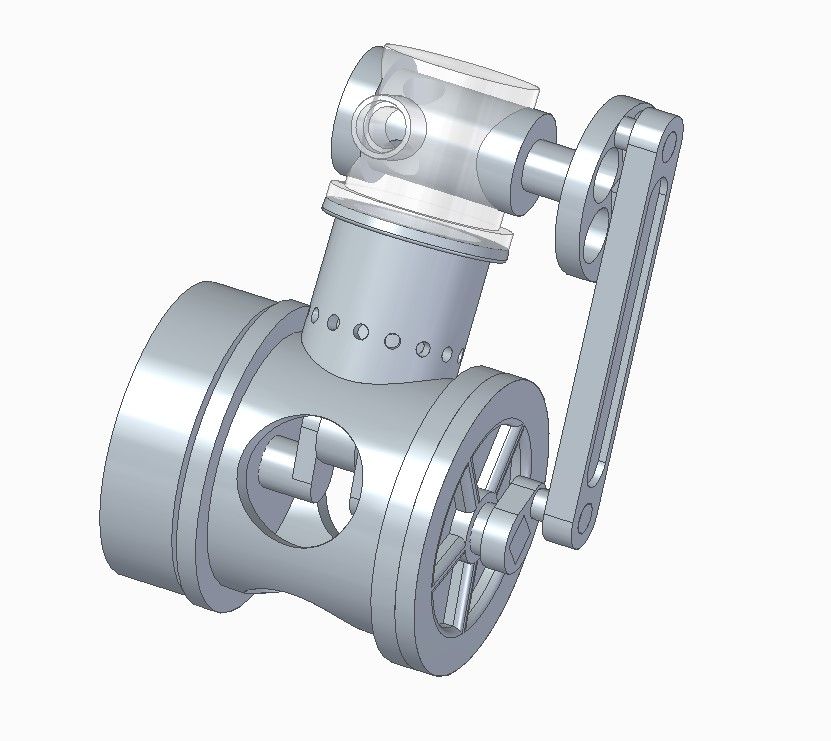

First attempt was this double acting horizontal mill engine, very much based on metal models such as the PottyMill.

Main interest is in the design of the piston, which is coned for strength and supported at both ends so it can float to reduce friction, and eliminate the need for a cross-head, maybe. The cylinder is generously honeycombed with passages to open up airflow, as is the valve. The valve is oversized compared with steam because there's less energy in compressed air at the same pressure. Don't like it – too conventional, too big, and too flimsy.

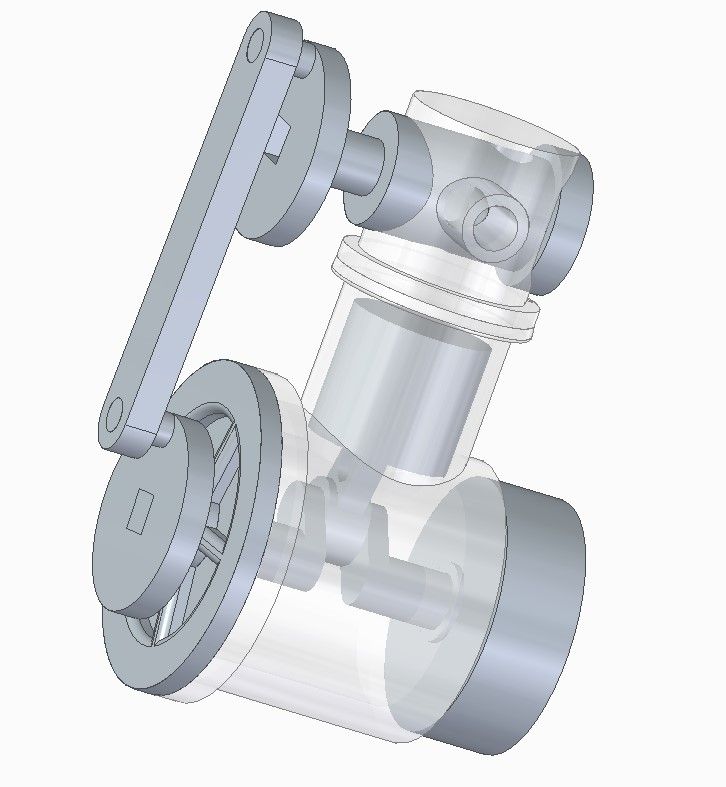

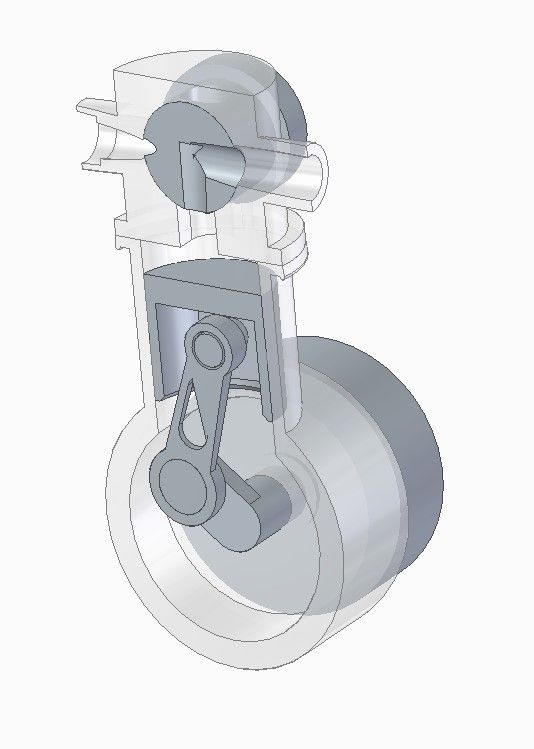

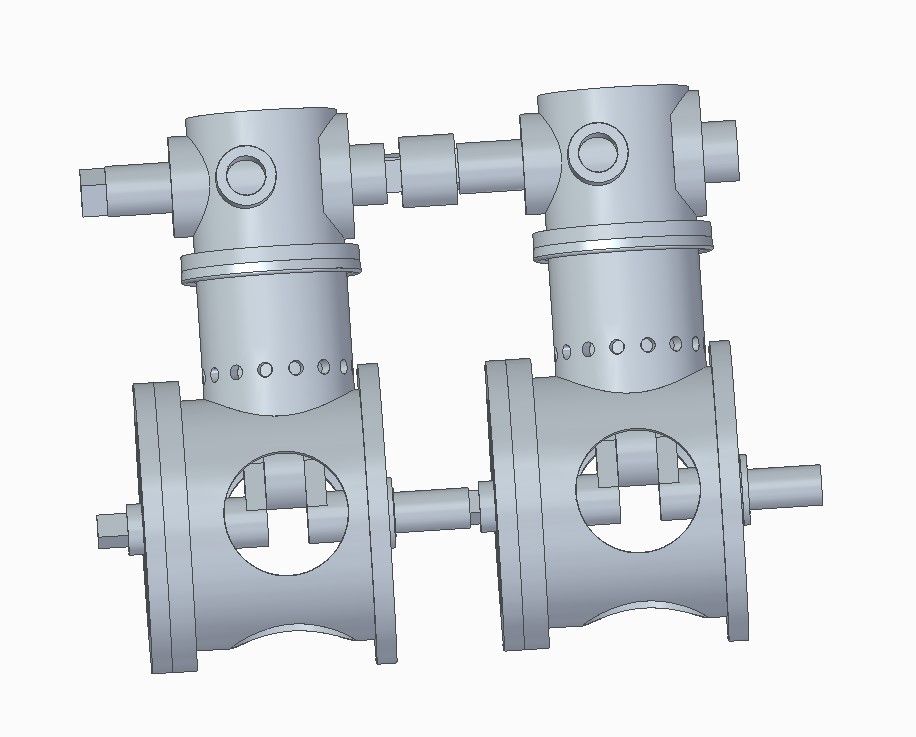

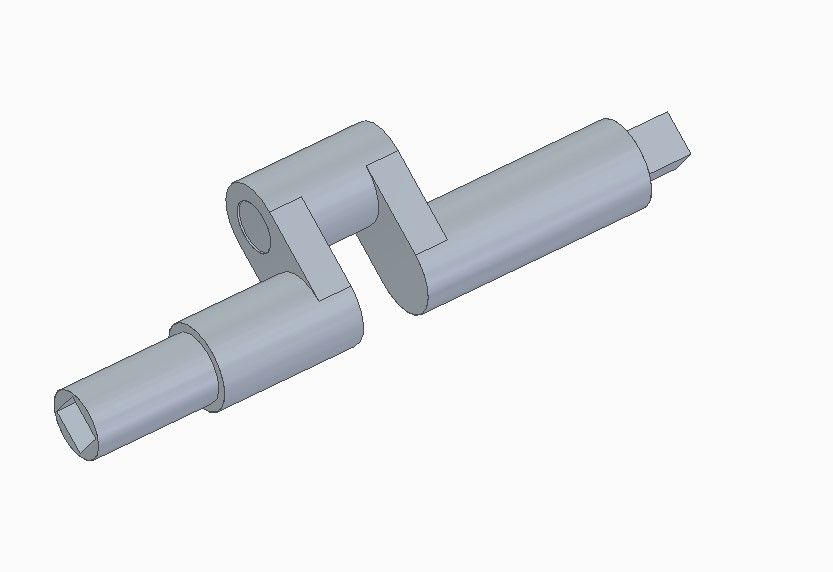

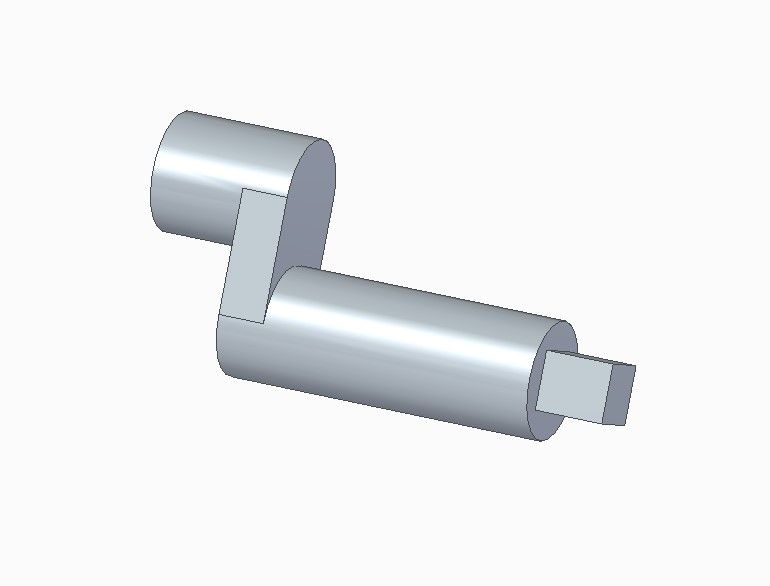

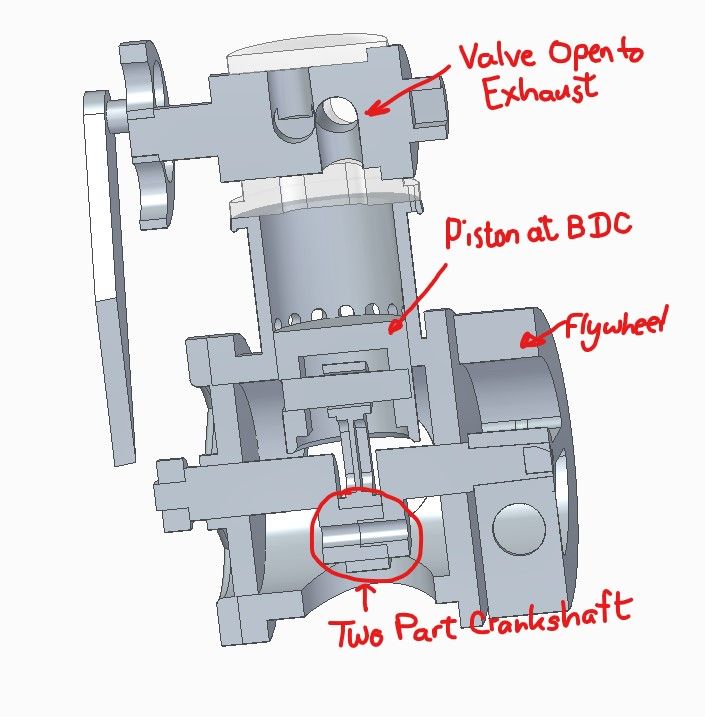

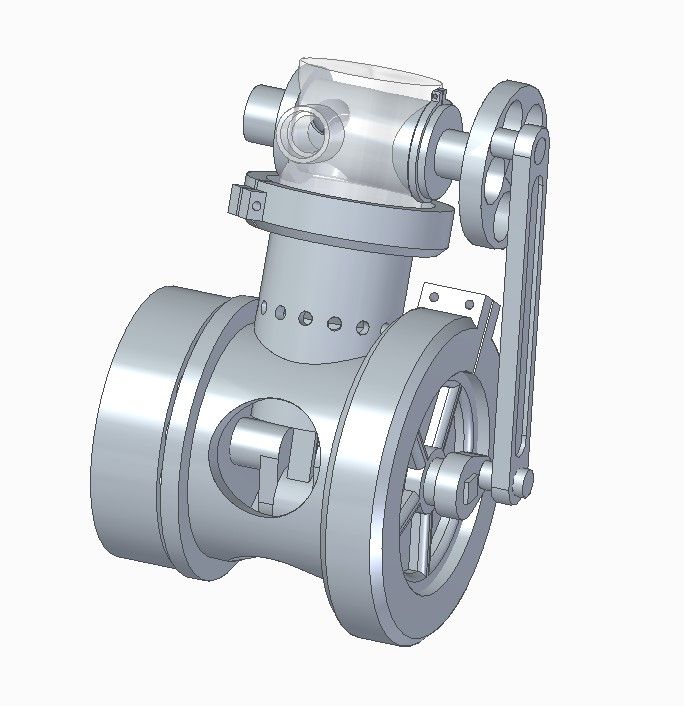

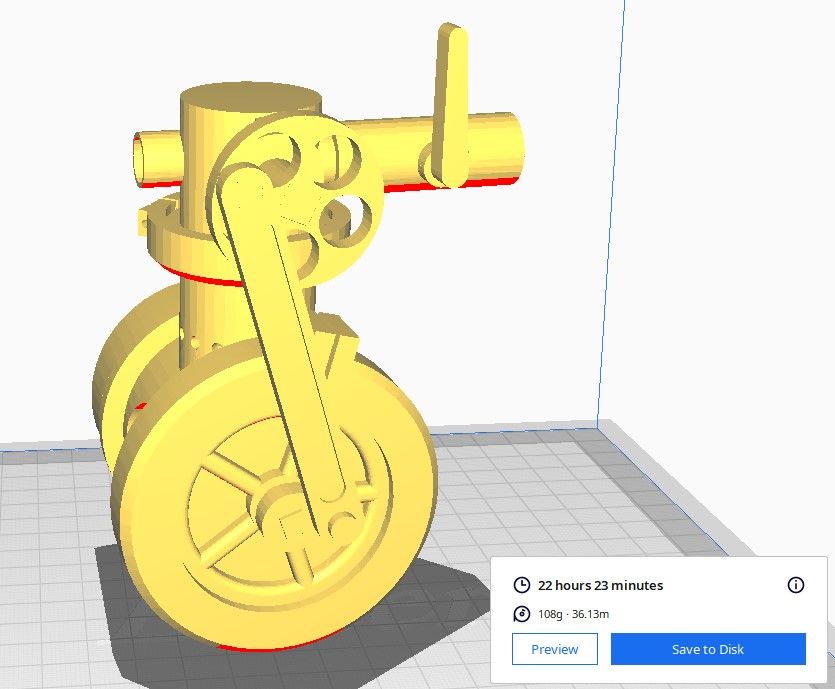

Rethink is this single action engine, which I think has more possibilities:

Section:

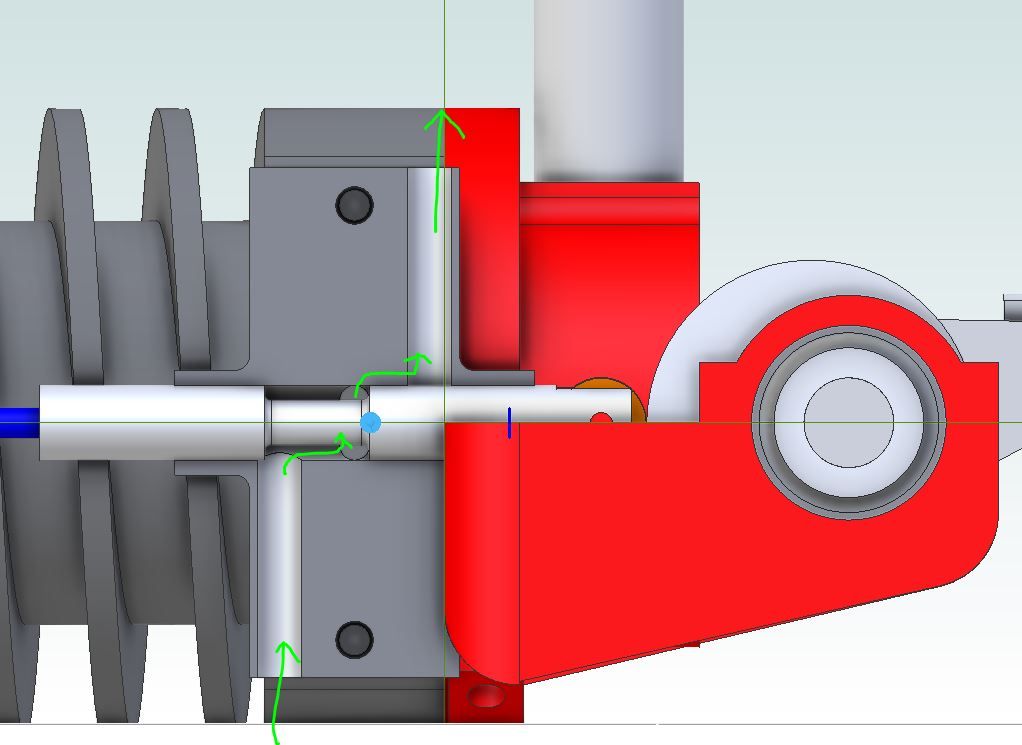

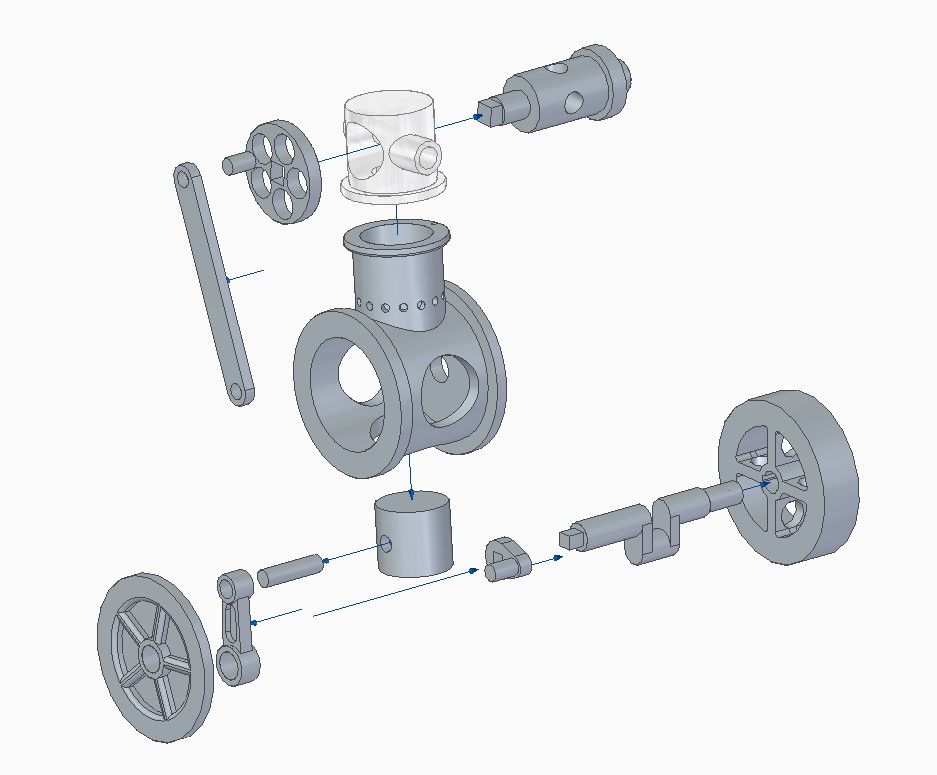

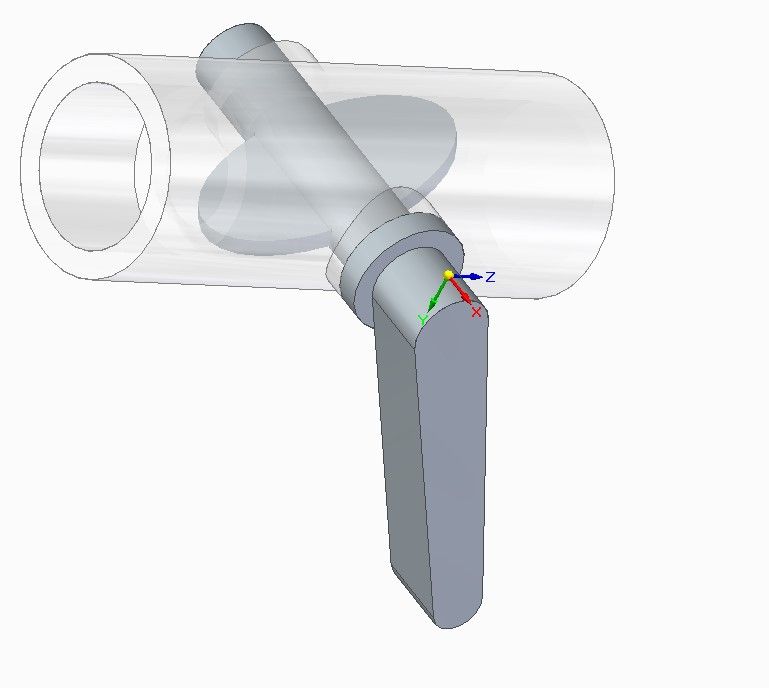

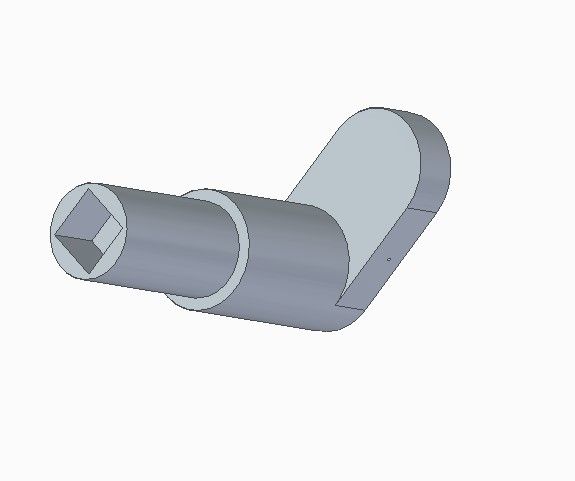

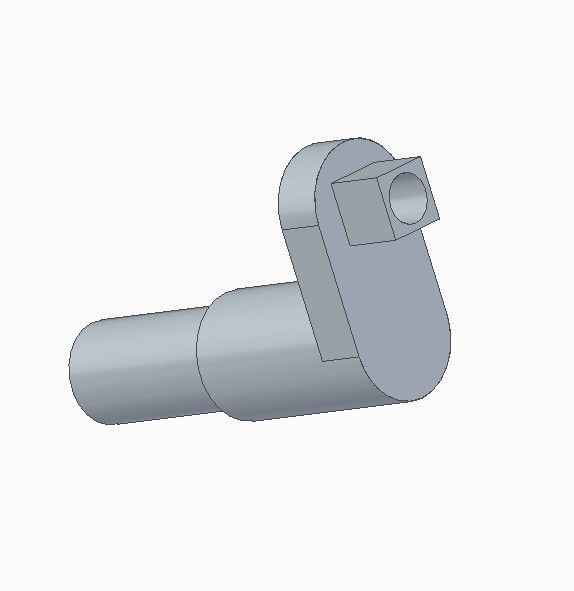

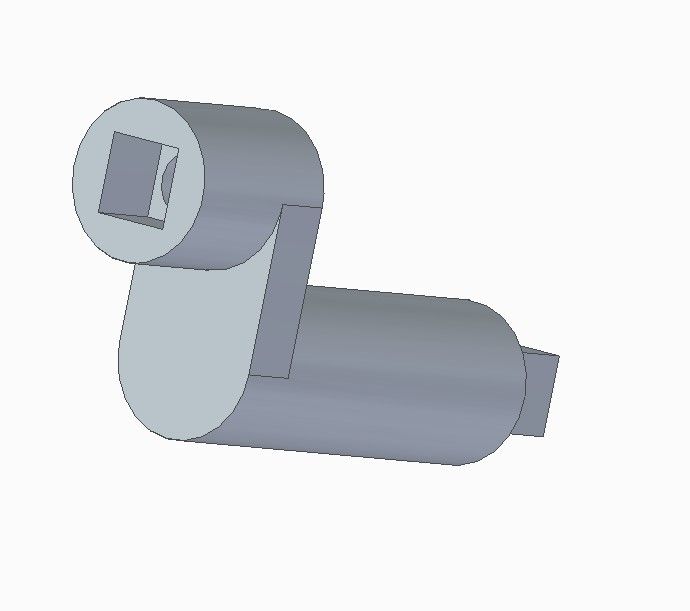

CAD has already saved me from a mistake. I have the rotary valve driven by a cranked rod, which is no good because it can flip as it goes over the top, completely ruining the timing:

Now my next job is replace the cranked wheels with sprockets and design something like a bicycle chain that can be 3D printed.

Lots of cause for concern already; friction is sky-high, there are no fasteners (I''m thinking plastic clips), the plastic isn't optimally proportioned, the valve can't fail to leak and the conrod has magically installed itself on the crankshaft.

Already thinking a 3D/metal hybrid would be a much better bet but I'll persist with printed plastic for the time being.

Comments and suggestions welcome! Yes it could be a step too far!

Dave

lee webster.