Posted by IanT on 17/10/2019 22:04:24:.

…

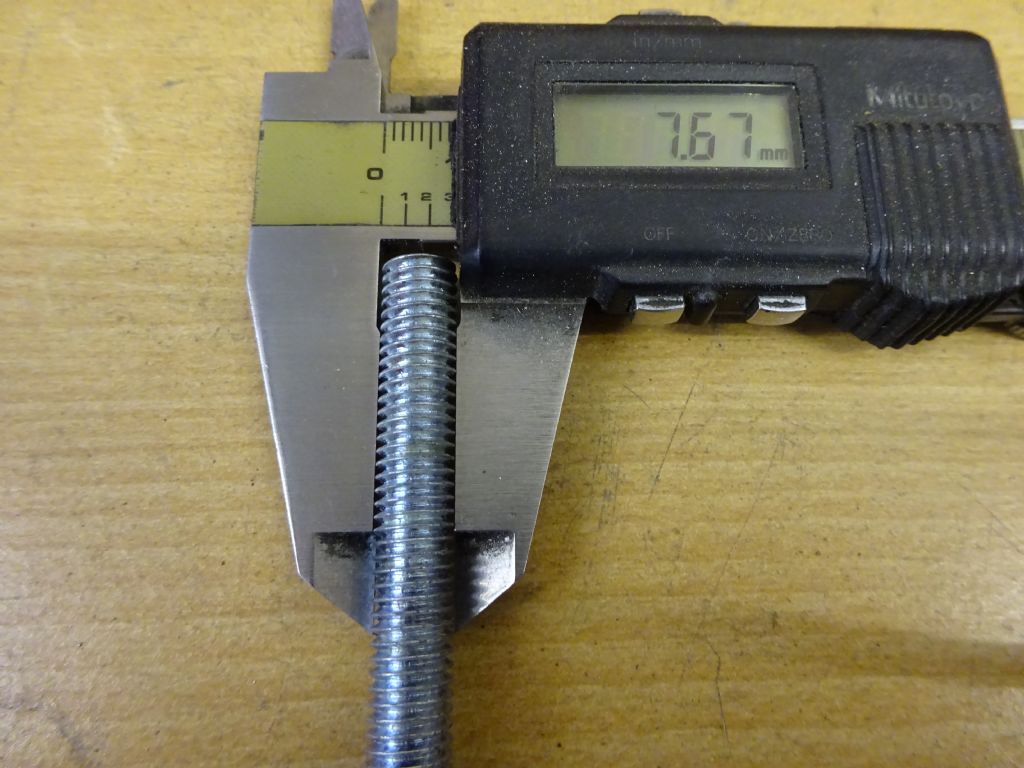

Instead I use the 65% flank engagement recommended by Tubal Cain in his ME Handbook (my copy is the 1993, 8th version – page 63) which for an 8mm (1.25mm pitch) thread is given as 7.1mm. These sizes work very well and makes tapping a far more relaxed process – and I've never been concerned about the strength of anything I've tapped using this thread engagement.

…

Oodles of good advice in Tubal Cain's Model Engineer's Handbook. I should read it more often!

In Section 4, he explains that most tap drill tables are designed for tapping machines fitted with slipping clutches and automatic reversers. He says: 'The tables are designed to accept the higher thread engagements found in production workshops are not suitable for hand tapping.'

Therefore his tables of tap drill sizes in Model Engineer's Handbook have been designed to give at least 65% engagement in small sizes (below 3/8" , and up to 75% for larger sizes. Thus he recommends 7.1mm for M8 rather than the usual 6.8mm.

, and up to 75% for larger sizes. Thus he recommends 7.1mm for M8 rather than the usual 6.8mm.

There's also a table of recommended engagements by material. This ranges from 50% for Stainless Steel (the nasty tough type, not the free-cutting variety) up to 70% in Brass and 75% in Cast Aluminium. He also points out higher engagements are needed when tapping sheet metal – at least 85%.

Dave

Howard Lewis.

, and up to 75% for larger sizes. Thus he recommends 7.1mm for M8 rather than the usual 6.8mm.

, and up to 75% for larger sizes. Thus he recommends 7.1mm for M8 rather than the usual 6.8mm.