I think the other Ian was referring to the threaded part at the back of the spindle rather than the spindle nose:

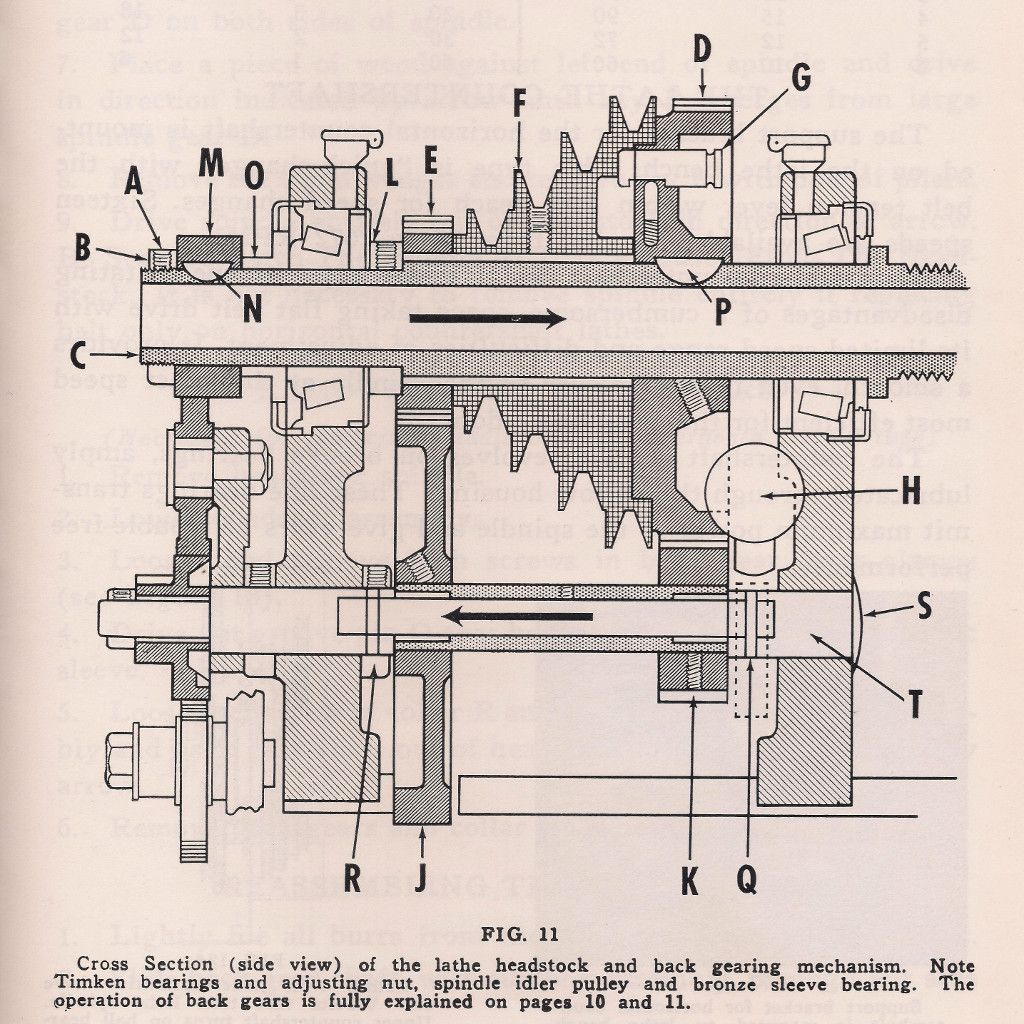

The threaded collar B applies the pre-load to the bearings. There is plenty of meat available to just turn off the old thread and cut a smaller diameter thread and make a new collar to suit. No need to change anything else.

The drawing is for the under-drive version with the back-gear under the spindle but the principle is the same.

To use the bearings without the flange, the inner oil baffles could be replaced with flanged retainers screwed to the inside of the headstock. You will have to be careful that they can support the pre-load which is set with the spindle at working temperature (about 25 C above ambient) by tightening the collar until all fore/aft play measured with a dial gauge is eliminated and then given another 1/16 of a turn.

If Ian L2 would like a copy of that drawing I have put a higher resolution version here

Russell.

Edited By Russell Eberhardt on 14/12/2014 17:11:50

Russell Eberhardt.

Russell Eberhardt.