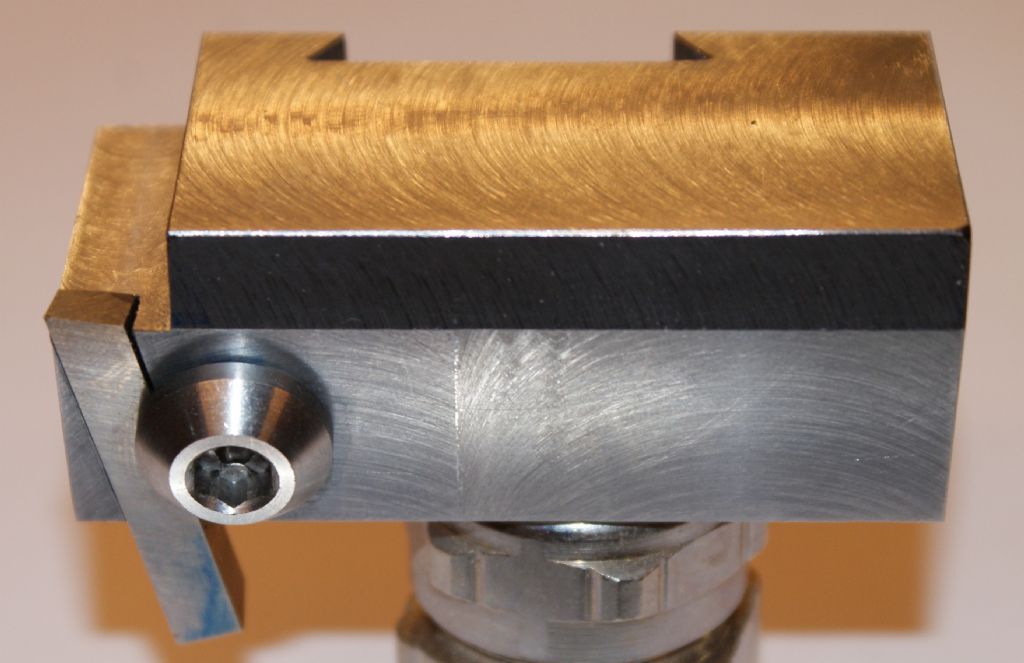

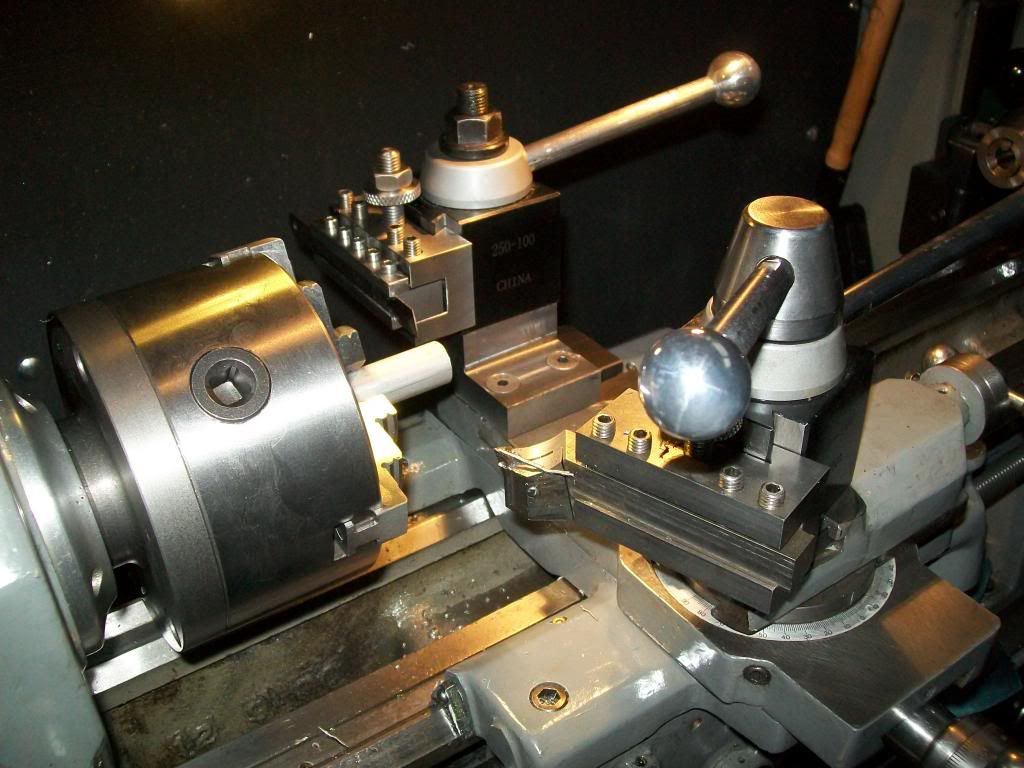

The tool shown in the Autumn 2009 M.E.W. article taking 1/8" toolbits gave such impressive results that, recently, I made up a beefed up version taking 5/16" toolbits.

Sharpening,

The original Sharpening Fixture called for a 20 degree angle, (corner to corner), but the drawing seemed to suggest that the angle of the bit would be 30 degrees. Maybe that meant along the side? Any comments?

The 30 degree angle recently mentioned will results in a thinner and weaker cutting edge.

My original sharpening jig was made to 20 degrees, and the 5/16 bit was ground to that on a Worden.

Both tools work well for me, (and for at least three others used on various lathes), having been sharpened at 20 degrees).

Using a 1/4 BSF clamp screw and nut, no sign of slippage has been evident, when taking a 0.100" cut.

It appears to be capable of taking a 0.0005" cut just as well!

I do like the idea of using a tapered wedge to clamp the bit; must try that.

Currently, it has made the usual CCMT060204 tipped tool redundant. Wonder how long the honeymoon will last? Seems to stand my brutality better, and so looks to be cheaper to run!

Am now starting a holder to take 1/8" round toolbits, for use as a finishing tool, to see if an even better surface finish can be produced, than the "standard" tool used at low speed with neat cutting oil.

Howard

Steve Withnell.