Thanks for the kind comments.

John H – Quite correct it was a 1/4HP induction motor not a synchronous one. My excuse is that it was late when I typed the posting.

Hollowpoint – I have not really used it in anger yet so can't really comment. However tests show good torque down to 400rpm on the motor (more than the induction motor) and adequate down to 200. That gives me 135rpm (400) and <68 (200). I can control the motor down to about 70rpm (26 rpm on the spindle), but there is no useable torque down there. Top speed is limited by the spindle bearings which are rated for 10,000 rpm.

Ian T – that looks exactly like the kit I got (down to the same remote control), however I decided against using the DC control board, display and remote as you did. Investigation of the motor power control (the black box) showed that the input from the control panel to the board was a simple 5v PWM signal and the 5v supply and input stage on the board within the power controller was fully isolated from the power side.

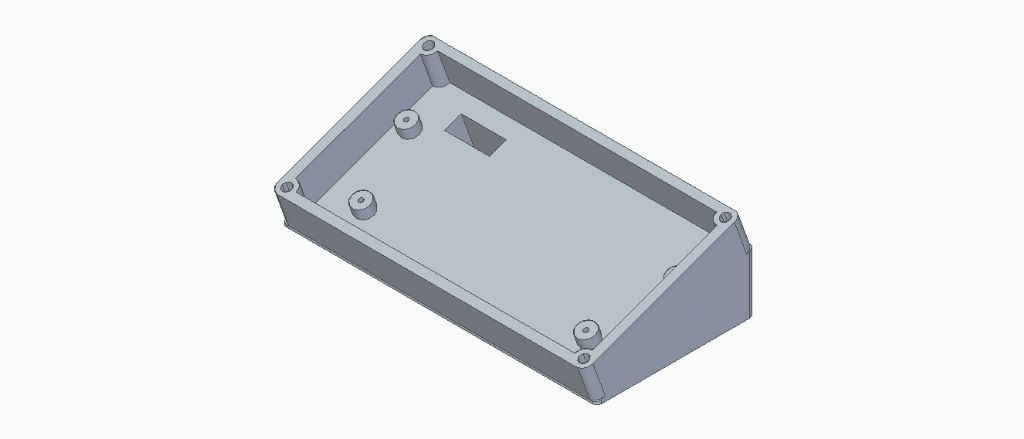

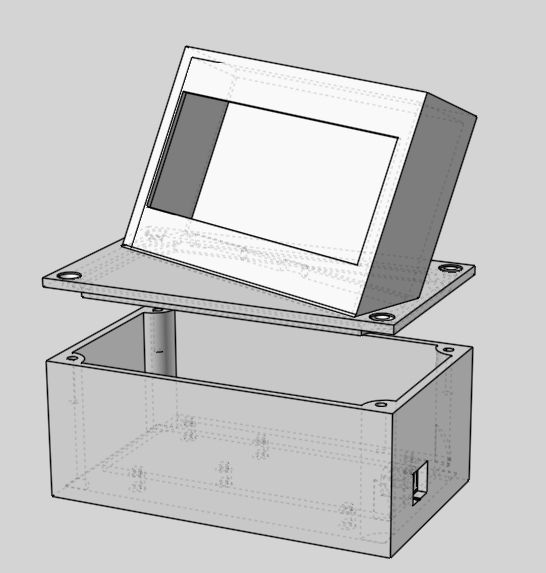

I decided to build an Arduino based controller (another learning curve) which would also measure and display the spindle speed. The display is a standard 4 * 20 character LCD display. Like you I designed (in my case using MOI) and printed a box for the Arduino, the interface circuitry and the display (two more steep learning curves – the box was my first attempt at 3D printing).

The speed measurement is by a Hall sensor (again standard Arduino kit) activated by a couple of small magnets let into the back of the spindle pulley. Another bit of 3D printing holds the sensor in place between the pulley and the back of the headstock. The control knob is a rotary encoder (I decided a simple pot was too coarse for the 0-4000 rpm of the motor). The run/stop switch and control knob are in a separate box so that I can move them about and find the best (most convenient) location before building them into the new baseboard.

In the longer run I plan to add feedback control to the spindle speed using the PID libraries available for the Arduino – but so far attempts to do so have ended in failure – I am going to have to get out my old control theory books to get the parameters right.

If anyone wants any more info, please let me know.

Robert Atkinson 2.

Robert Atkinson 2.