Is it time to review the requirement?

Tom asked:

'I have a Colchester Bantam, with a single speed motor. I am looking for a 2 speed motor for it, and want to be prepared, so need to find out about how to install the switching.'

and John Haine (motor guru) quickly suggested: 'Why not just fit an inverter and have done with it?' Good question!

Some awkward technical problems to be solved fitting a two-speed motor to a lathe:

- Two speed motors need native 3-phase – fortunately Tom has this already.

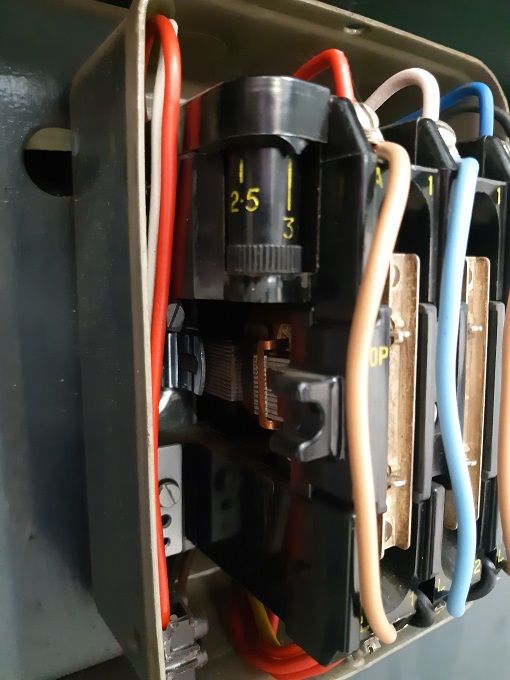

- The control circuitry needed by two speed motors is unusually complicated and in this case there is no diagram to work from (yet). It may be necessary to design a control circuit, a task beyond the skills of many competent electricians.

- There are two different types of 2-speed 3-phase motor and we don't know for sure what Tom has. (Though Alan Johnson said 'From your motor nameplate photograph, you have a two pole / four pole three phase motor' I see the motor plate mentions 3350, 2800, 1740 and 1450 rpm. Important to identify the motor type, Dahlander or what, and the rpm needed from the motor, which depends on the lathe's belts / gearing. Will also be necessary to identify the windings, not always obvious on second-hand motors.

- Once the circuit is established, the contactors, wiring, and switches have to be bought and fitted. Won't be cheap.

Tom said: 'The main reason for not going down the VFD route was that I want a higher chuck speed than the inverter delivers.' As VFDs can spin motors faster than their plate speed, Tom may be applying the wrong solution. Possibly Tom doesn't want a two speed motor, he wants a lathe capable of a certain rpm.

Digging round the web, Tom is the only example I found of anyone replacing a motor/VFD with a two speed motor. I did find examples of people going the other way, ie permanently wiring two speed motors in the fast position and speed controlling with a VFD.

As two-speed motors make life difficult, I'd want to be sure there was a really good reason for fitting one. Gut feel on this, I'd simplify the requirement, probably doing the job with a single speed motor and VFD. Cheaper and easier than a two-speed motor, plus the VFD provides fine speed control.

Always a good idea in engineering to nail the requirement if you can rather than jumping straight to a technical solution. Usually worth checking the options, including 'Do Nothing'!

Dave

Edited By SillyOldDuffer on 28/08/2020 10:09:06

Tom Walker 1.