The strange straight edge(s) being used for the dovetails on the column were made to scrape the dovetails under the table, and on the top of the knee.

One surface was scraped flat as a reference, and one edge machined and scraped @ 55°

It was a section cut off an old cast iron fishplate 12" square, originally used for clamping 50V bus bars together, hence the holes at each end.

Once the main face of the Z axis was flat, my next task was to get one of the dovetails straight and at the correct 55° angle to the face.

I used a combination of the long parallel, to get it straight, and these buts bolted together to get the angle right.

The top part in cream paint, was the bit made out of the busbar clamp, as a dovetail straight edge.

It's bolted to another piece of steel plate, I'd machined and scraped flat, and kept parallel to it with the small 1-2-3 blocks. This allowed me to generate the long dovetail at exactly 55° to the flat front of the Z column.

I didn't try too hard to keep it exactly vertical, but again had a good start, as the very ends were still unworn from the factory. I took very little off the middle, and scraped the ends down to match the centre.

I then had two reference surfaces, the front, and one dovetail.

Next job was to create the second dovetail.

Again, I tried to measure everything by two different methods.

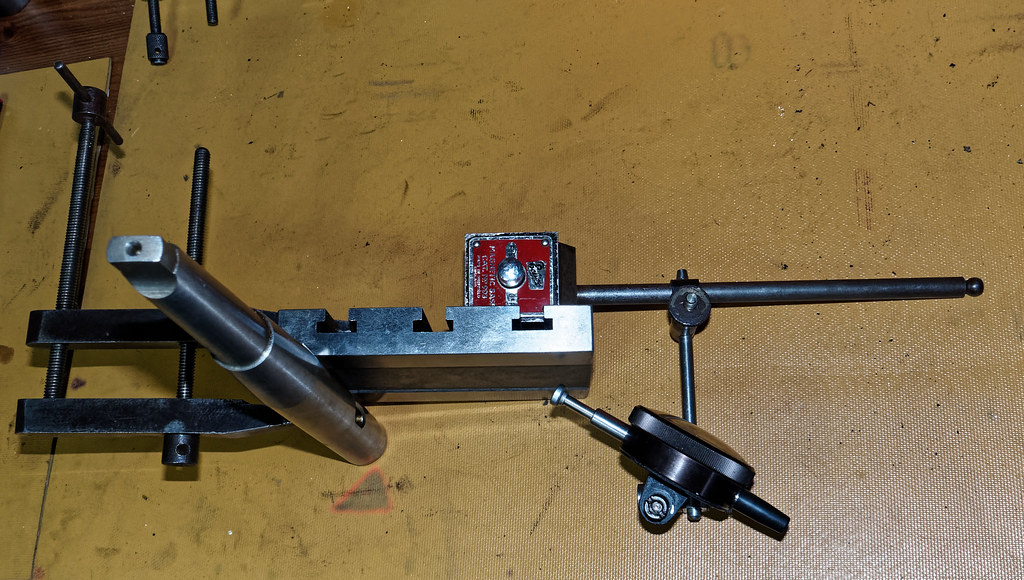

I used the arrangement above, as a sliding carriage, to hold a mag base with a finger clock to measure the wear on the opposite dovetail. I don't think there's a photo of that.

Here's my second method, using a simple surface block and a finger clock.

The round bit is a hollow ground pin off something, but you could use anything; a gudgeon pin would be ideal

This was for the initial measurements using a thou clock, though later in the process I used a thenths one.

The assembly in the top photo was used to keep a check on the angle, and the long parallel to keep it straight.

Bill

p.s. each of the photos in the Flickr album has an explanatory note, if you view the individual photo page.

Edited By peak4 on 06/08/2022 13:06:07

Steve355.