In my case, the wear was so much on the main table and the top of the knee, that it was the obvious place.

Both ends of the underside of the table were higher than the centre of it due to wear, as it overhangs in use.

Similarly the top of the knee was worn down at the ends, rather than the middle.

This meant that the table followed a slight arc, rather than a horizontal plane.

A workpiece 6" long and flat on one side, was about 6 thou thicker in the middle than the ends.

As such this is where I started, only deciding to get involved in the column later.

It's perhaps the wrong approach, compared to the chap in the video, but I didn't have a large enough surface table to work on the face of the column.

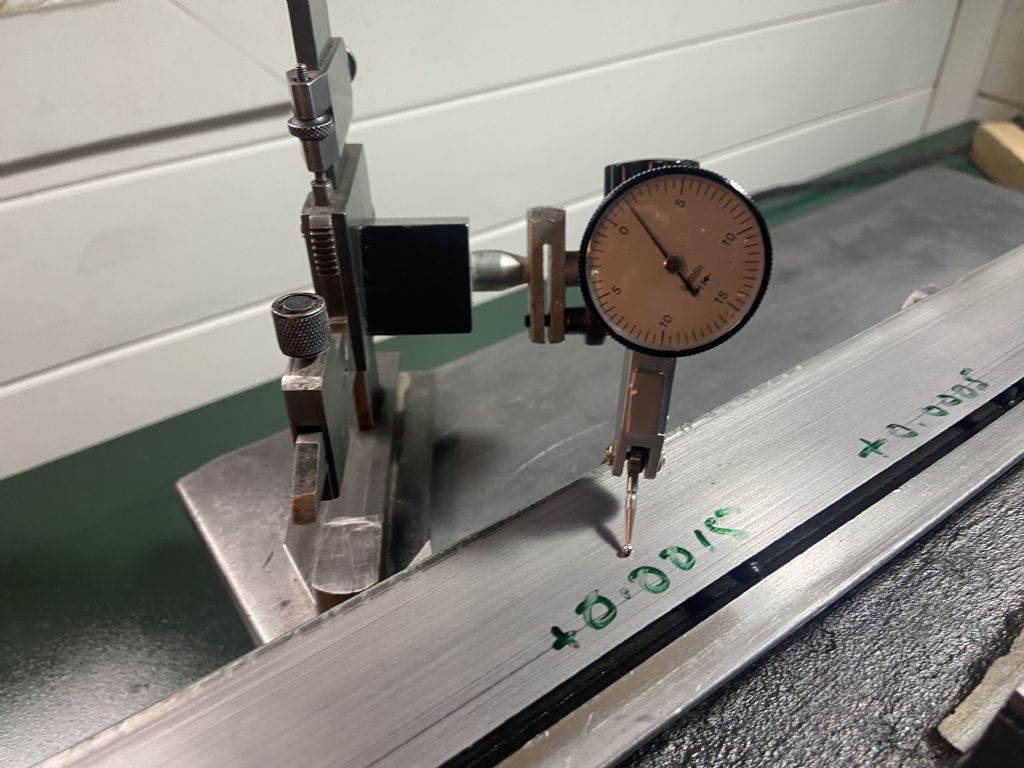

I scraped the top of the table flat to my surface plate; that is flat, but not removing any indentations, as that would have been too much work. I also flattened and squared the front edge @ 90°

This gave me two planes to act as datums for all other measurements.

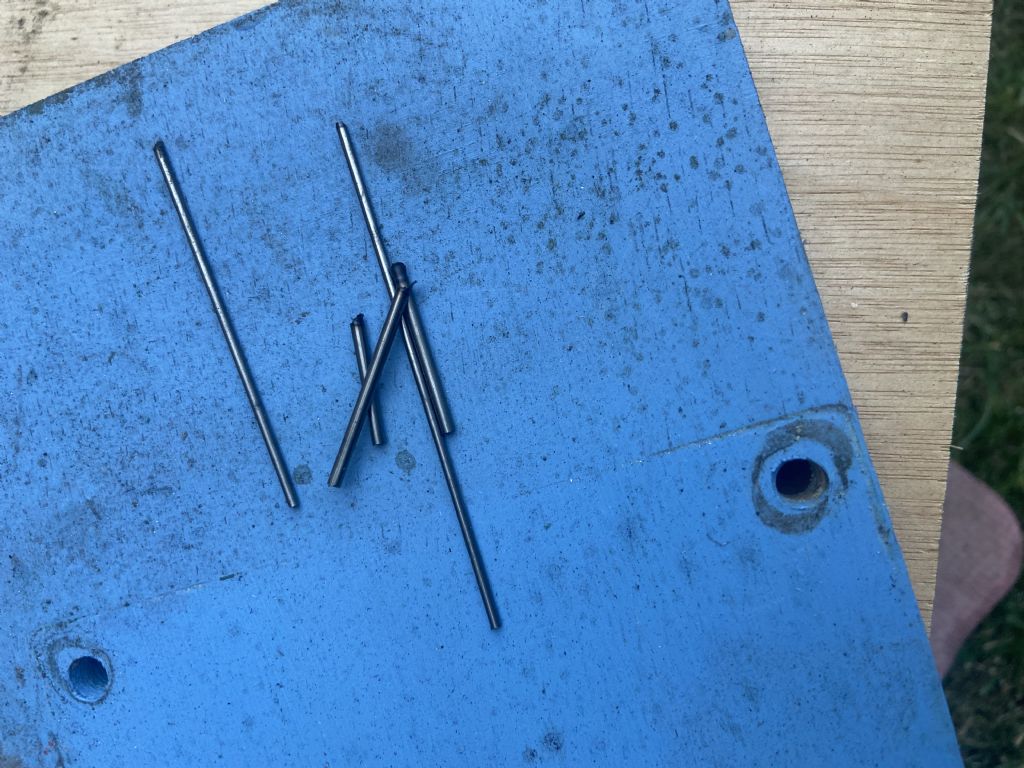

I then worked on bottom flats, and then the dovetails underneath the table, which need to be parallel, straight and in line with the front. The two ends of the bottom of the table needed something like 12 and 15 thou taking off to get them parallel to the top. Lots of elbow grease and re-sharpening of carbide scrapers.

I used my spare Myford, with a home made magnetic faceplate and diamond disk for the sharpening, the saddle was wound out of the way, and an angled table used to present the scraper at the correct angle.

Obviously everything was well taped up, and I used a mask to avoid inhaling carbide dust.

There is a photo in the album somewhere.

Everything else followed on from that, but the advantage of flattening the top of the table first, was that it effectively gave me a long portable surface plate to work on the column later on, as well as allowing me to get the top and bottom of the table in two parallel planes.

Whilst I did do some milling on the Centec, all of it could have been done on my DW Mk1, though mine is a long column machine.

The swivelling head meant that I could traverse a longer workpiece, than the travel on the DW's table.

Bill

Edited By peak4 on 31/07/2022 14:46:38

Steve355.