Thanks for further replies.

soi keo blogfb88 – thank you for taking the time to respond, and welcome to the forum. If you re-read my opening post you will see that I had already considered the possibility that I was cutting a screw thread before I posted, and rejected the hypothesis for reasons given in that post.

To wind this up (for me, for the present at least) I dug out the 4-way TP which came with the machine. When I bought the lathe (new) from Axminster it came with the QC mounted, and I just went along and used it without much thought.

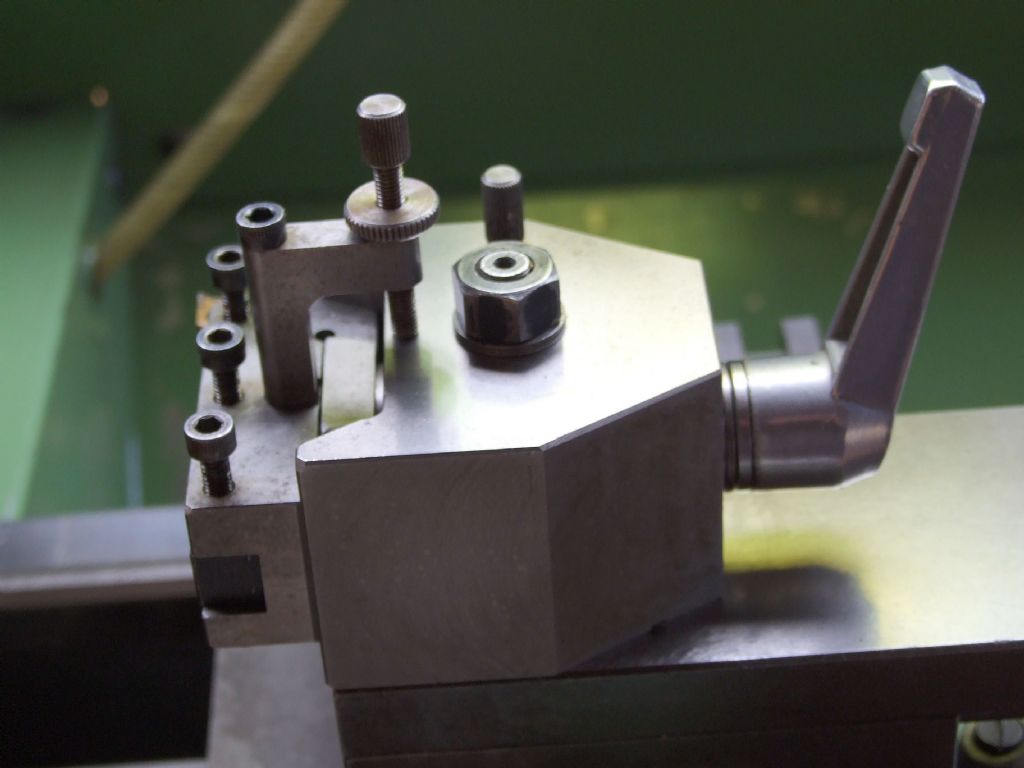

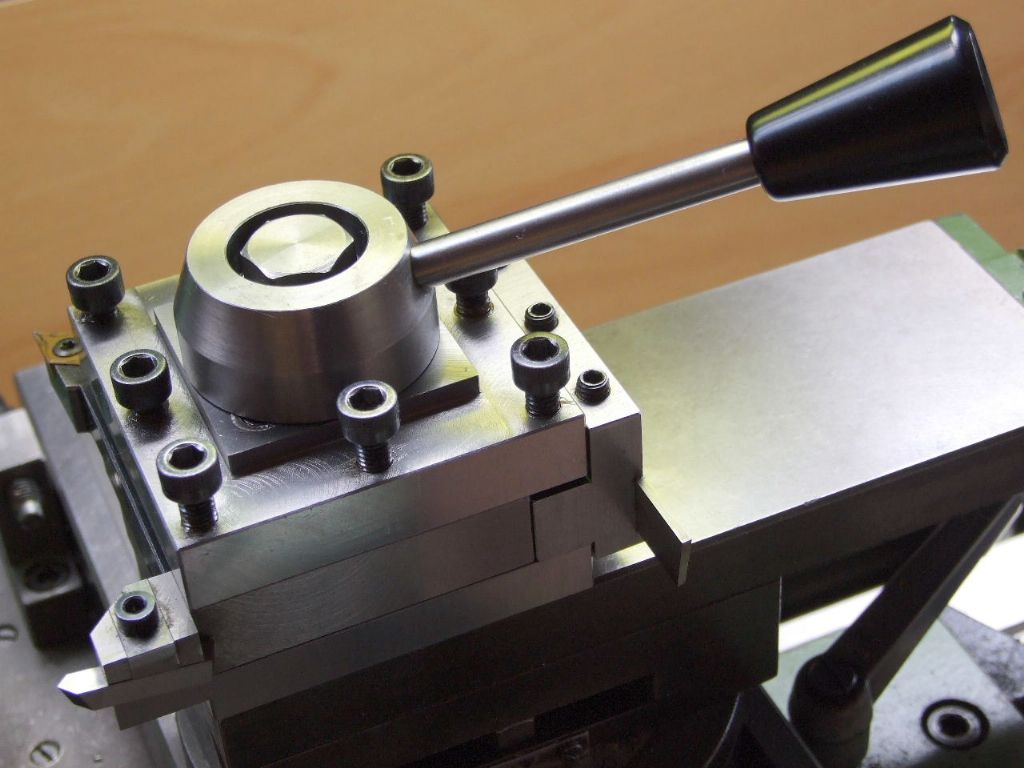

I put the 4-way in place:

shimmed up a tool (PITA) and tried a cut under the same conditions as in my OP:

OK, not wonderful, but no 'screw thread' or other weird patterns at different spindle speeds.

Eventually, after further experiments using the 4-way the part I was trying to make came out like this, straight off the lathe:

Well, OK, I polished the winding handle, but the rest is as-turned. I'm pretty happy with that. Well, f*****g delighted actually.

Many thanks, and especially to Graham Meek who pointed me in a direction which wasn't on my compass, but seems to be the way to go..

Robin.

Edited By Robin Graham on 04/07/2021 23:10:21

Robin Graham.