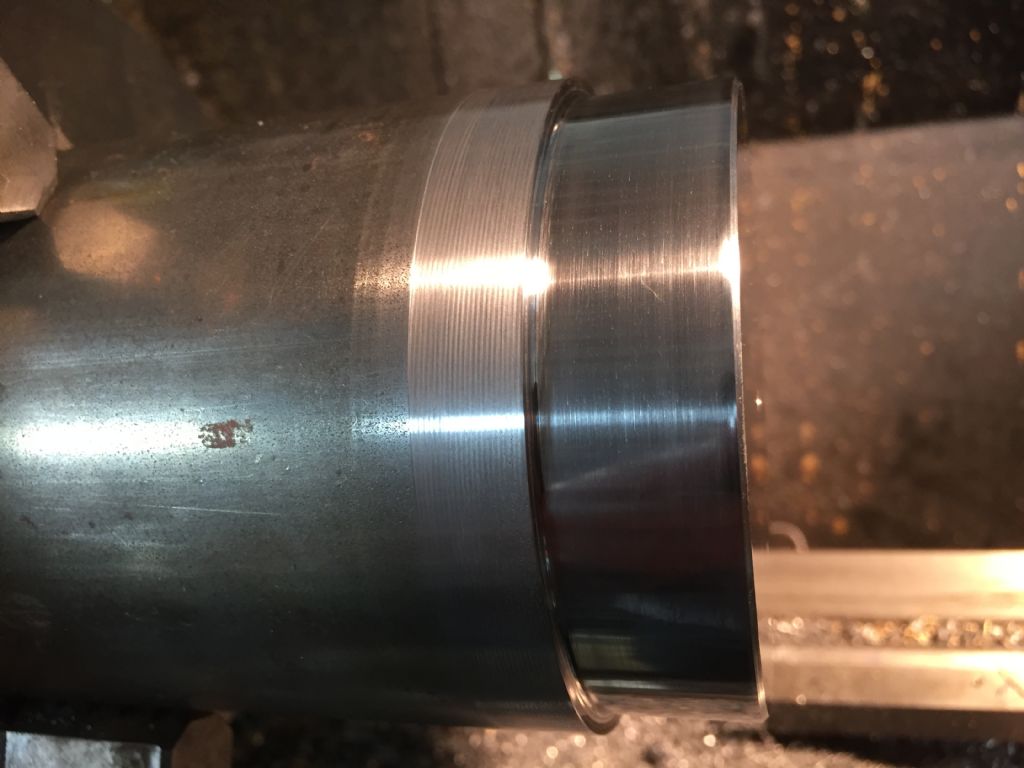

I'm at my wit's end trying to diagnose the underlying cause of this problem. I was turning some 3.5 inch EN1A today and was unable to get a decent finish, despite trying a number of tools, speeds and feeds. An example:

On the larger diameter part of the work you can perhaps see something resembling a fine screw thread. An immediate reaction would be that the feed is wrong for the tool tip radius, and it is indeed a fine screw thread. But it's more complicated than that – the 'pitch' of the pattern has no simple relationship to turning speed and feed. In fact certain speed/feed combinations give a sort of cross-hatched pattern, like right and left hand threads intersecting.

I've spent an afternoon experimenting with various tools – both carbide and HSS, and different speed and feeds, but always see some variation on this theme. Can anyone shed light?

Ancillary info:

– The lathe is a single-phase 1.5kW gearhead – fairly rigid, about 600kg.

– I don't notice the effect on work below ~2.5 inches in diameter.

– The same thing happens with or without tailstock support.

Robin

Edited By Robin Graham on 26/06/2021 23:48:07

Edited By Robin Graham on 27/06/2021 00:26:26

Robin Graham.