Hi Gordon and welcome to 2014!

It's always hard to offer good advice from just a short description and the odd photo. My initial reaction was that you were trying to make too large a cut with a 'finishing' tool and that there might also be some form of slippage in your "drive train" as a result.

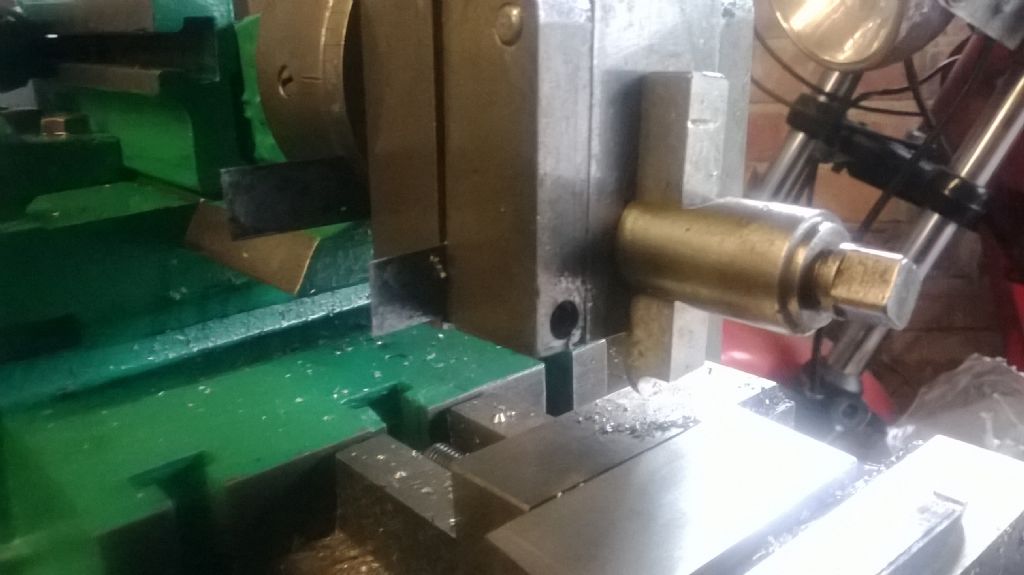

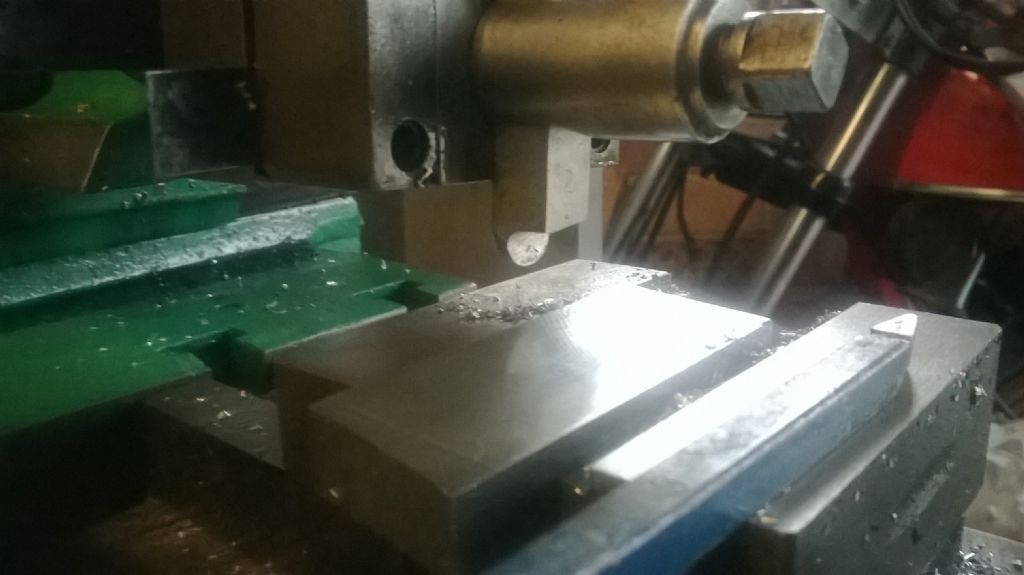

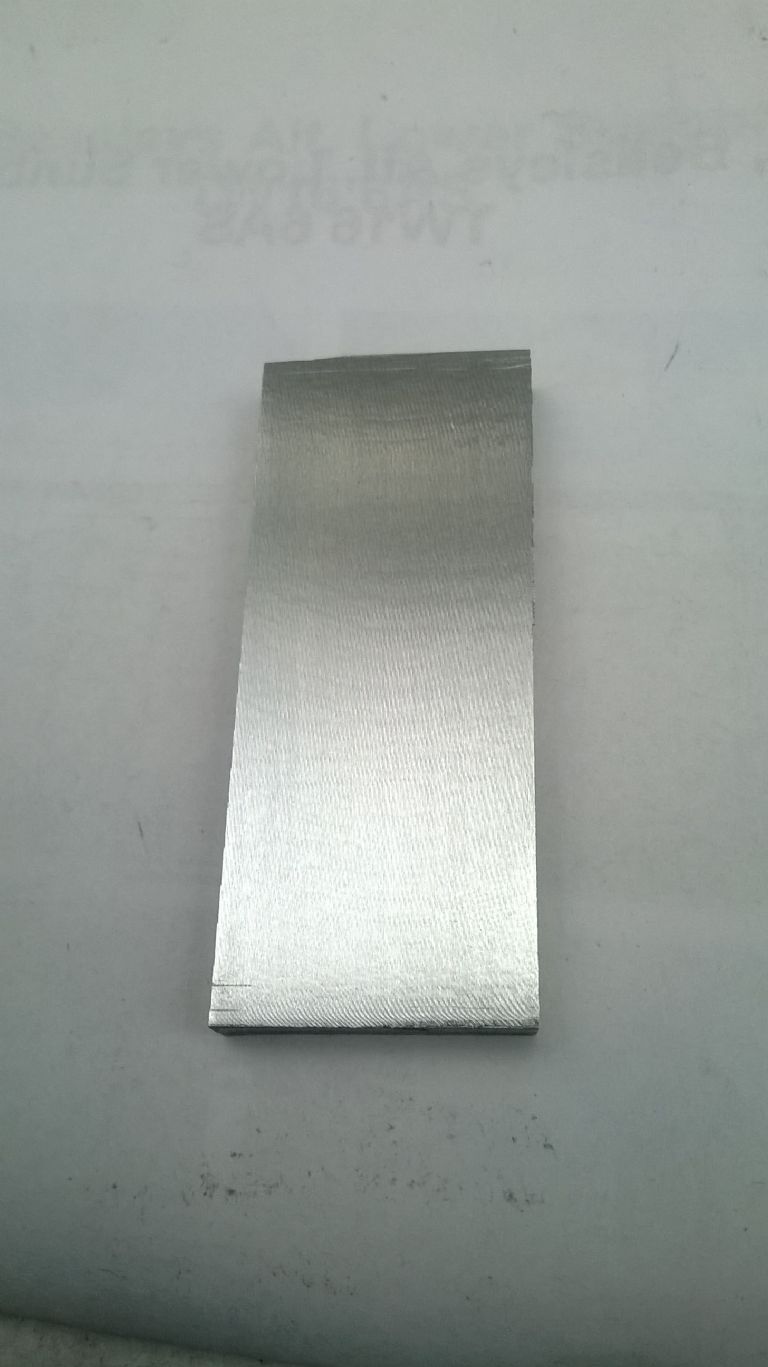

You seem to be moving in the right direction with respect to tooling (your 'V' shaped tool is a good start) and I would suggest that you look next at the speed you are running the Shaper at (try slowing down), together with the ratio between the 'feed' rate versus the depth of cut. I'd suggest you try slightly wider feeds with shallower cuts to begin with (as opposed to a shorter feed and a deeper cut). Until you can get a fairly good finish using the V tool, I wouldn't worry too much about using 'finishing' tooling – they are exactly what the name suggests – for finishing.

I would also check for any movement of the ram (when extended) by clamping a DTI to it and seeing how much movement you have (similar check to gripping a bar in a lathe's 3 jaw and seeing how much movement the headstock bearings will allow). There will be some movement but hopefully not excessive. You should really only adjust the gibs when the slide is disconnected from the drive and it can be moved freely (and I don't know if this is possible for the powered Adept).

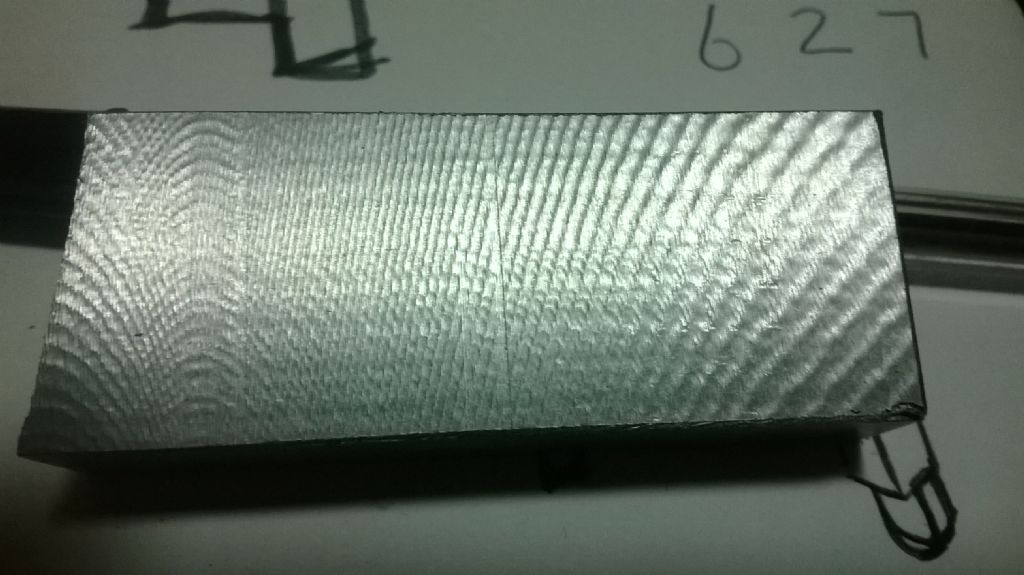

Finally, the finish will also be a function of the type of material you are trying to cut Try various materials and see if things improve..

In summary, I would suggest that you "fault find" by only changing one thing (variable) at a time, looking for any changes in the cut quality and keeping notes as you go. 'Trial and Error' will work for you, provided you are methodical.

Regards,

Ian T

Ian S C.