Well just an awesome thread.

Must admit that I hadn't been following it at all and last night saw it was into 8 pages then so sat down and had a read.

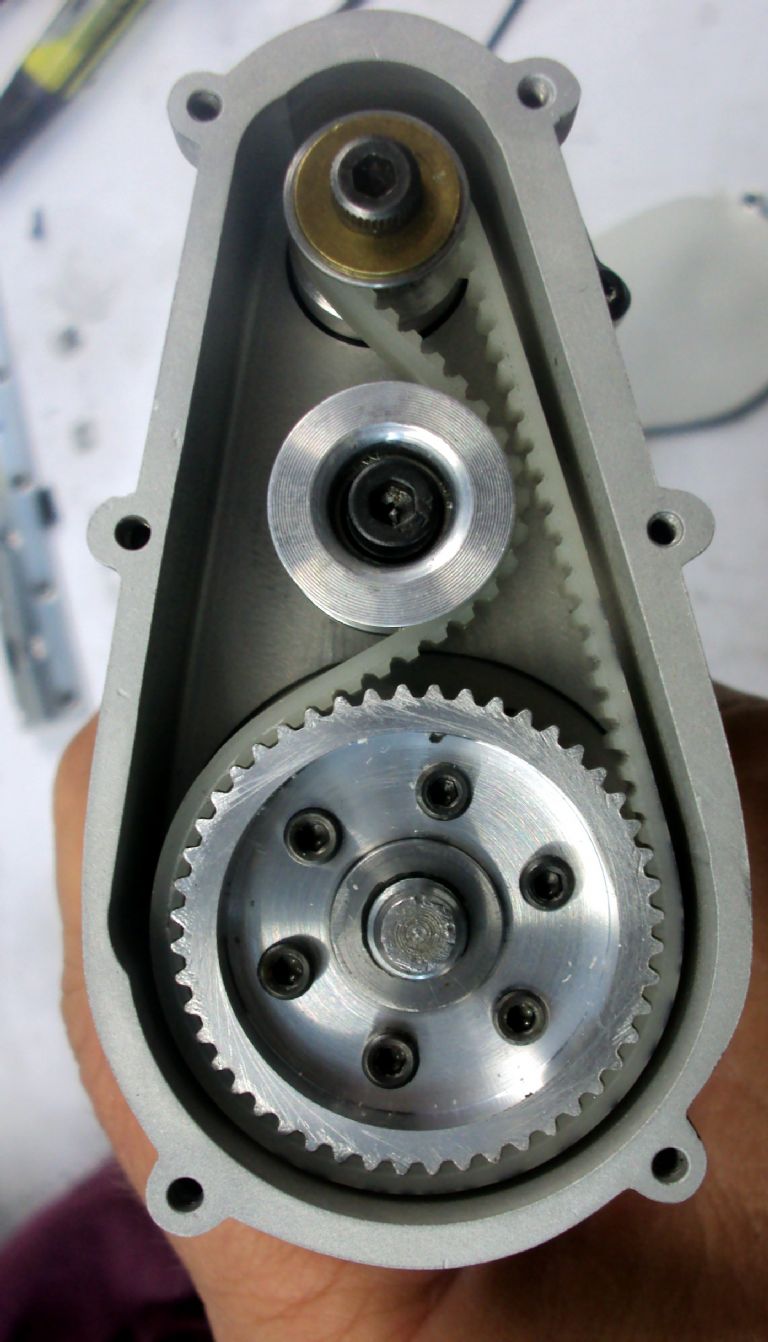

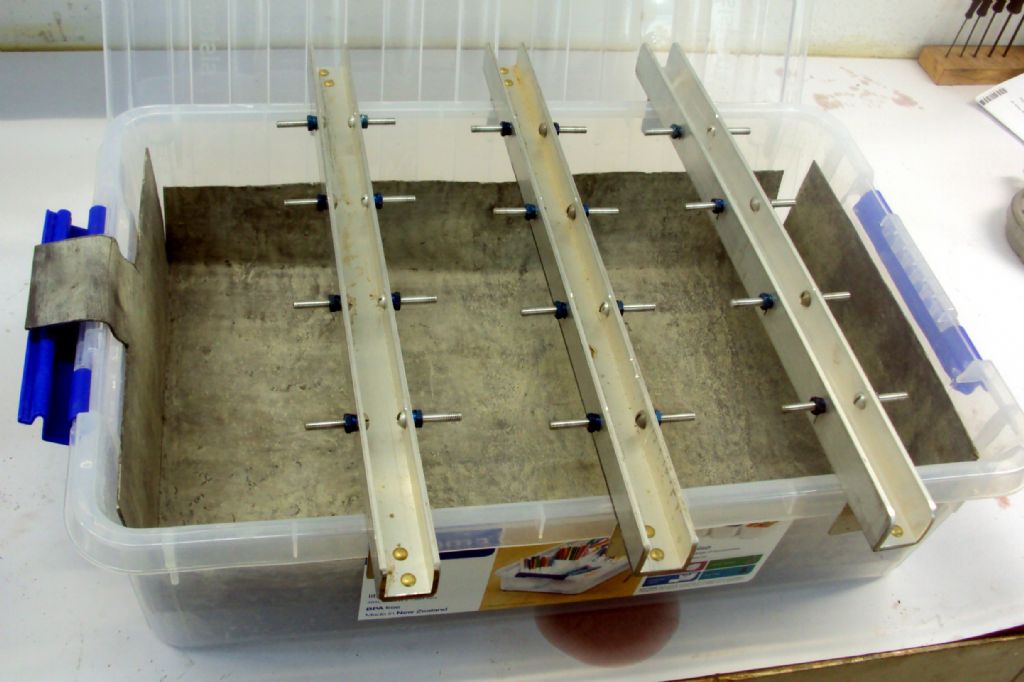

Totally blown away both by the quality of workmanship and the speed of the build given how many parts need making and the complexity.

What really made it for me though was the single minded dogged approach to the whole project.

I must admit I was starting to feel sorry for Dean after a couple of pages of nearly everyone saying it wouldn't work and the description was wrong. Many adding their experiences of having leaned against one when a lad which obviously makes them an ex-spurt.

But no our intrepid hero, Dean puts all this aside together with his bent crank, and quadruple bypass herniated appendix and just gets on with it to prove to all the doubters that he can do it and it works.

Just the right amount of pictures and information to keep everybody interested without them falling off their chairs.

Unlike a recent post where we had 20,000 pictures of a main bearing cap and then the poster fell out his pram. He'd do well to read a post such as this.

Well done Dean and I would not be surprised to see your name in the Joe Martin Museum of Craftsmen in the future.

Michael Gilligan.

Michael Gilligan.