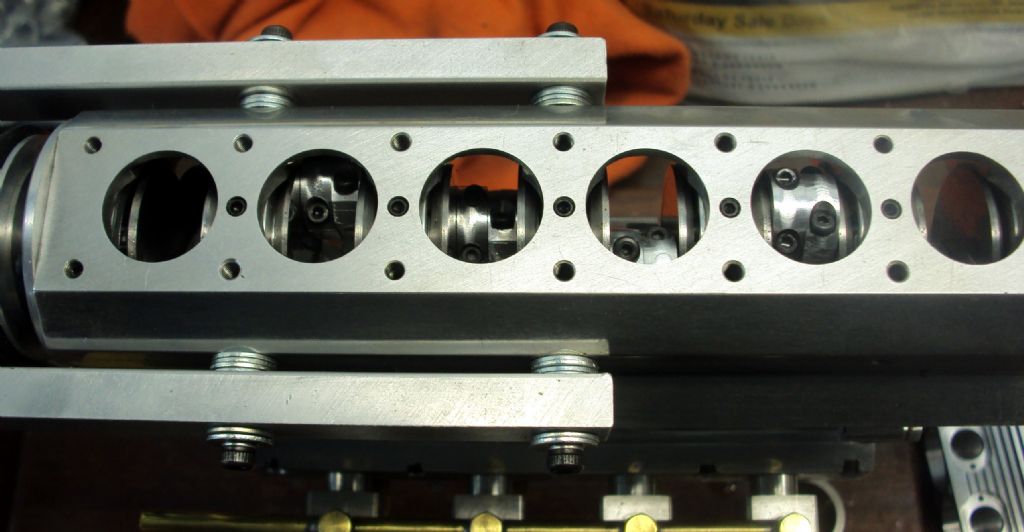

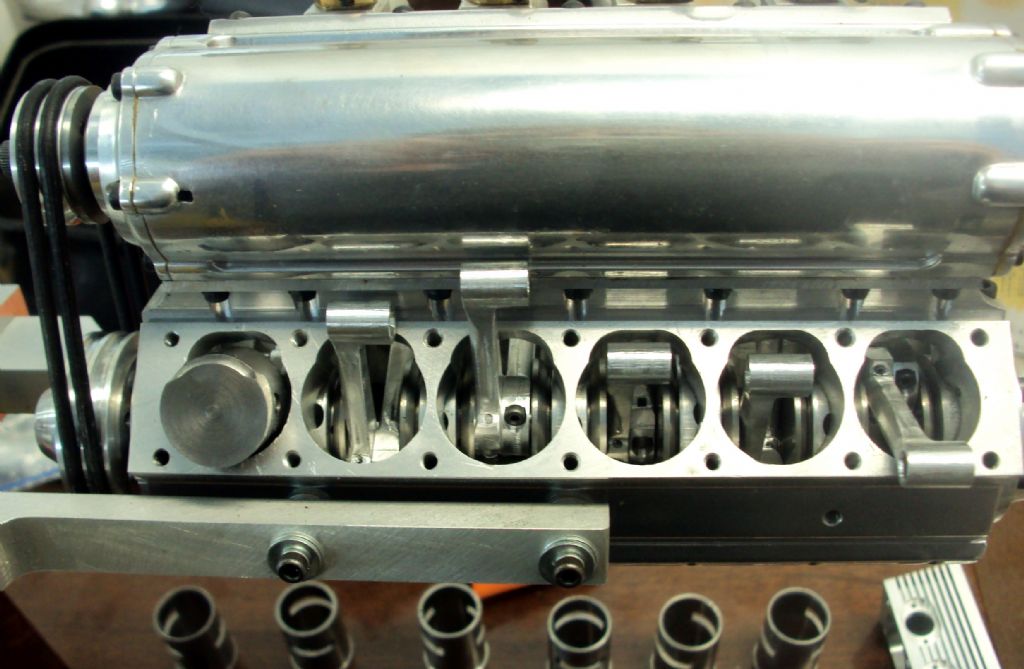

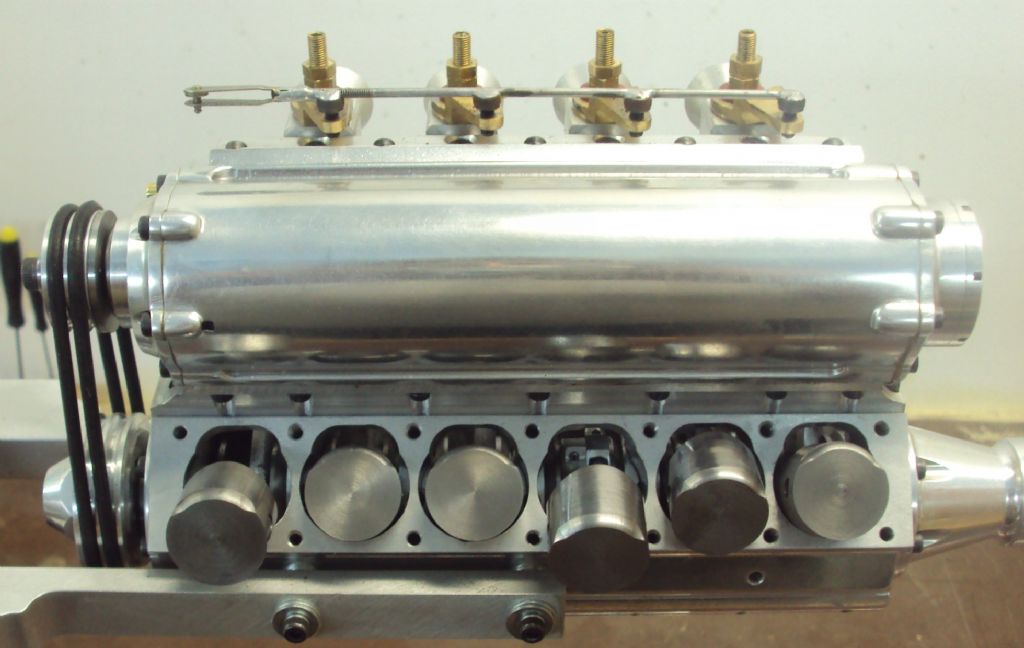

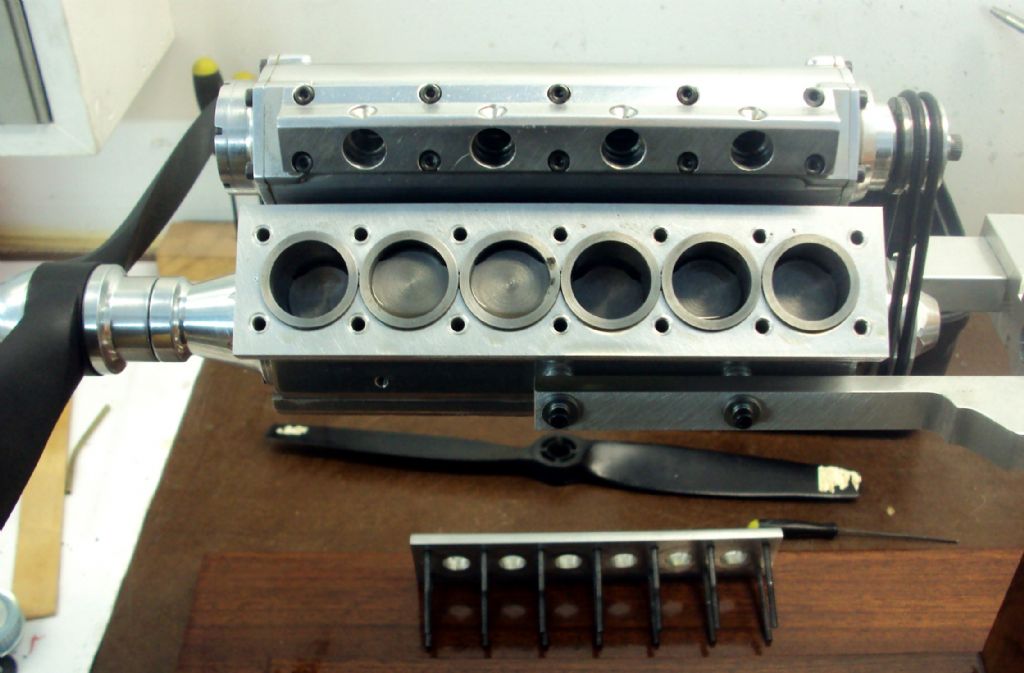

Well here we are at the next stage of machining the pistons, The first step in stage two was to cut the step into the piston skirt. There are three reason for this, firstly to allow clearance for the piston at BDC from the center main bearings and secondly to give a sealing skirt over the exhaust ports at TDC.Lastly just for some lightening effect. Next they were set up centered in the mill to machine the conrod little end space into the underside of the piston and then lastly, all pistons were machined at the crown end to the final overall length. Photos below show progress to date.

This photo shows the setup to machine the conrod little end recess.

Don't ask about the piston on the left………………… Yea lets just not go there OK.

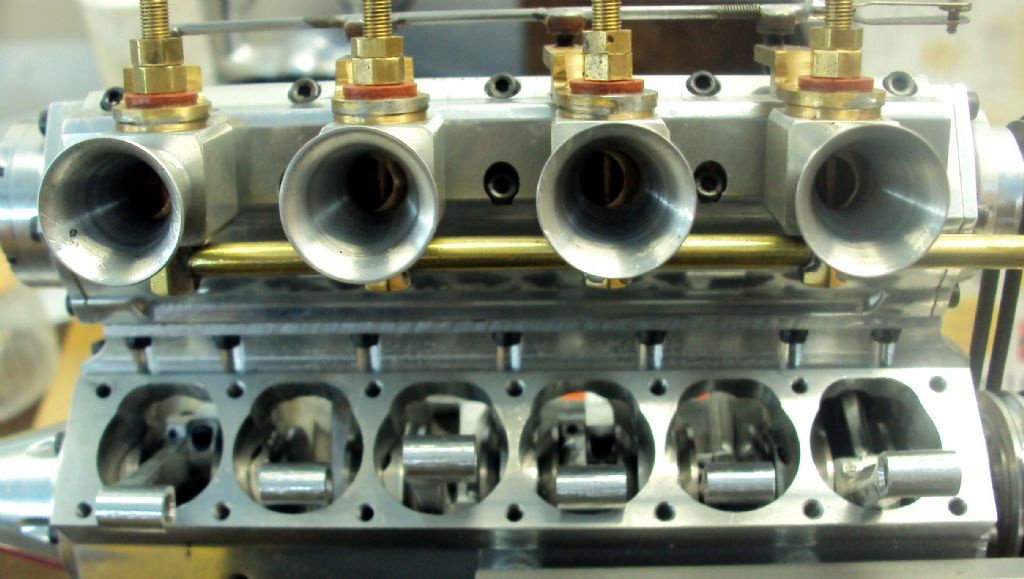

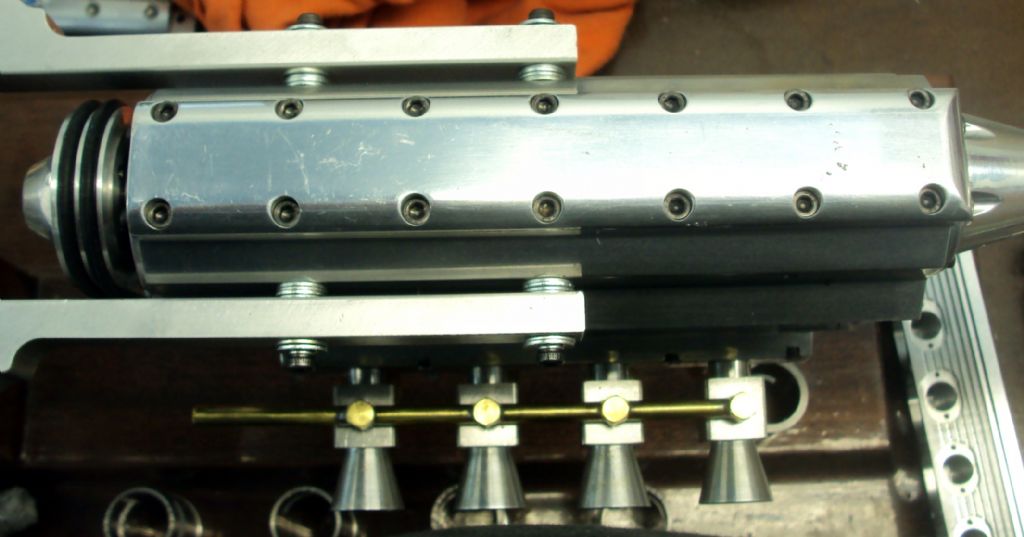

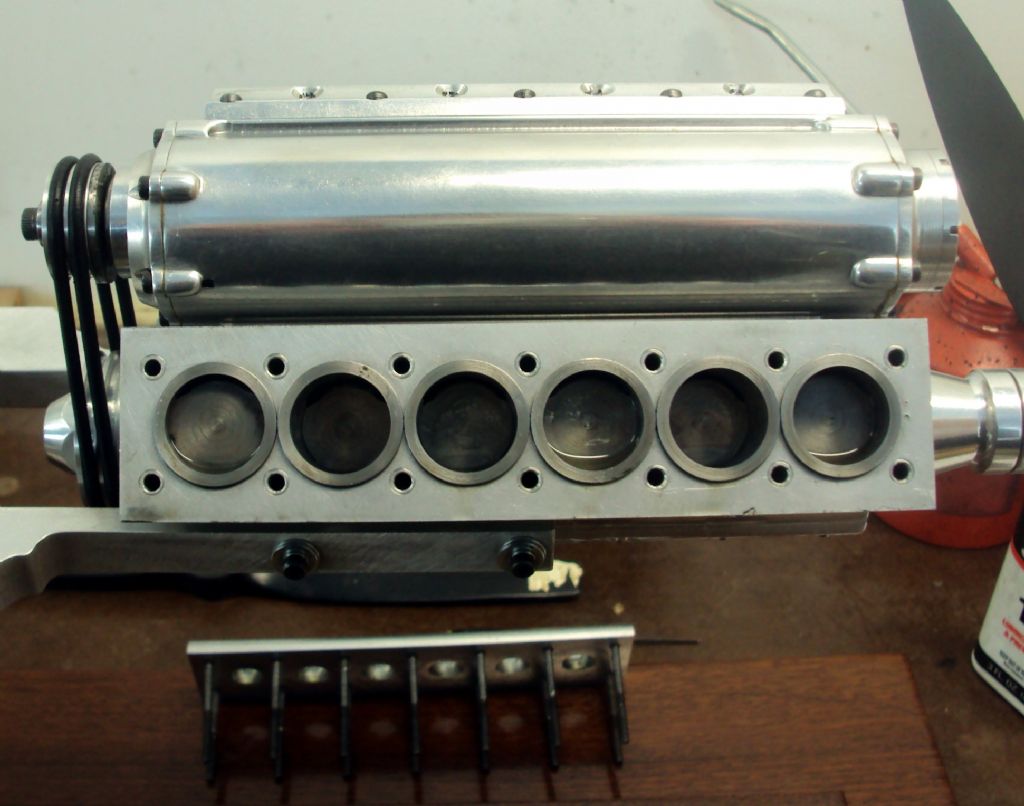

The photo below shows the fixture used to turn the crown down to length, which will also be used to turn the diameter to lap to the liner

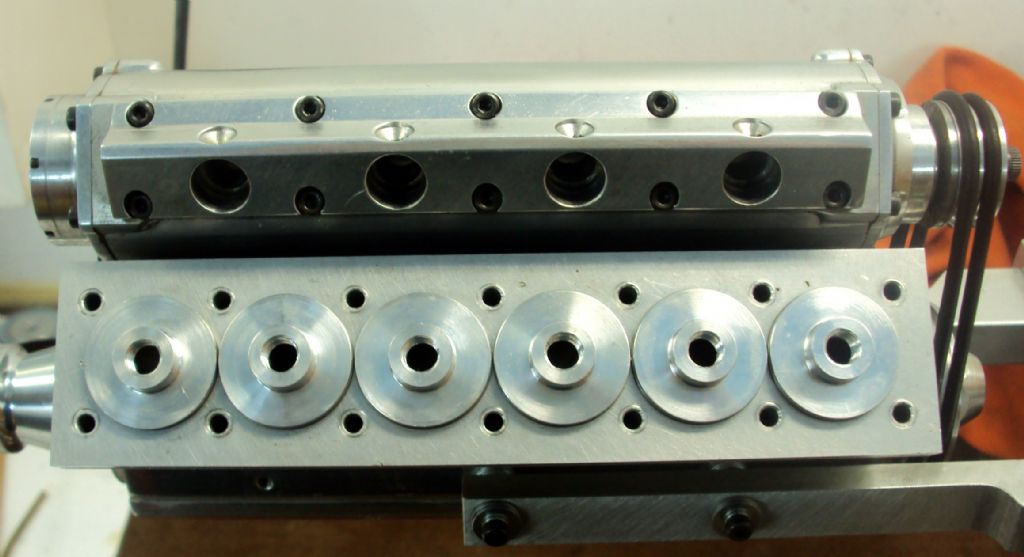

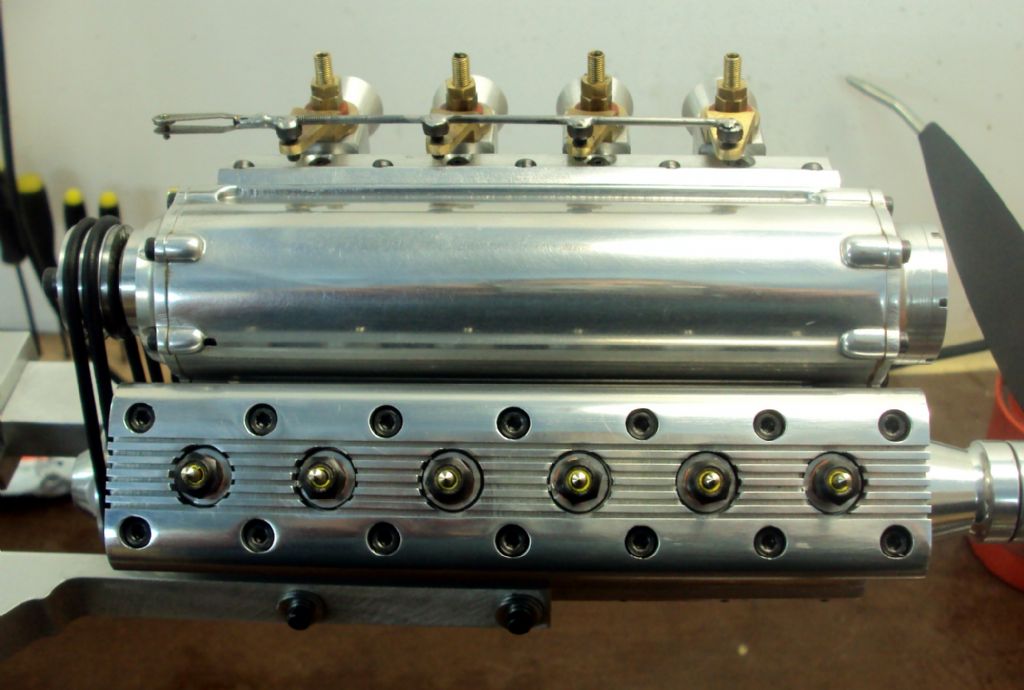

Here are the 12 pistons finished to the end of stage 2. Next is to machine the transfer advance step into the crown, the object of this is to advance the transfer timing so that it opens approx 10 deg's before the exhaust and therefore stays open 10 deg's after the exhaust. The point of this is to allow a small amount of exhaust gas into the transfer port to reduce the loss of fuel mixture out the exhaust on transfer. With approx 25 psi boost pressure there will be plenty of SUPERCHARGE in the combustion chamber on the compression stroke.

Well that's all folks see you again soon

Cheers

Dean

Michael Gilligan.

Michael Gilligan.