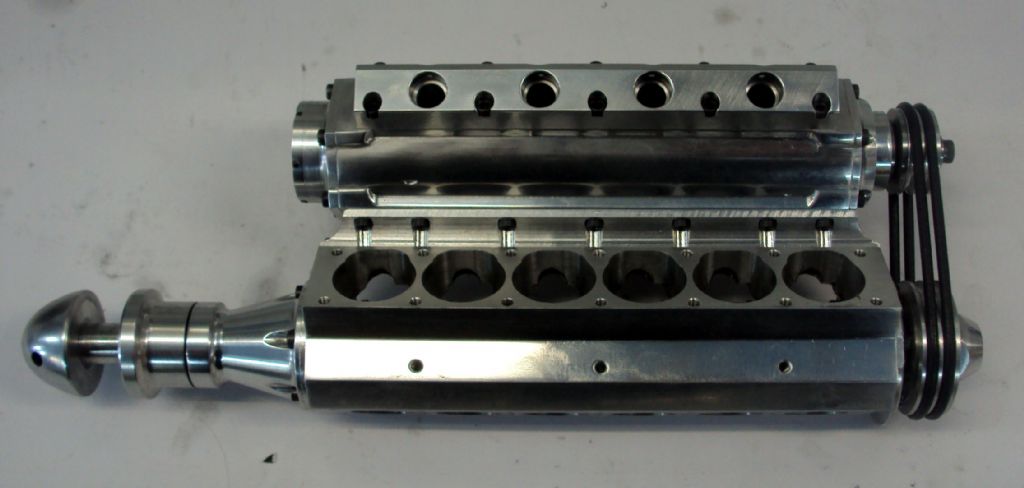

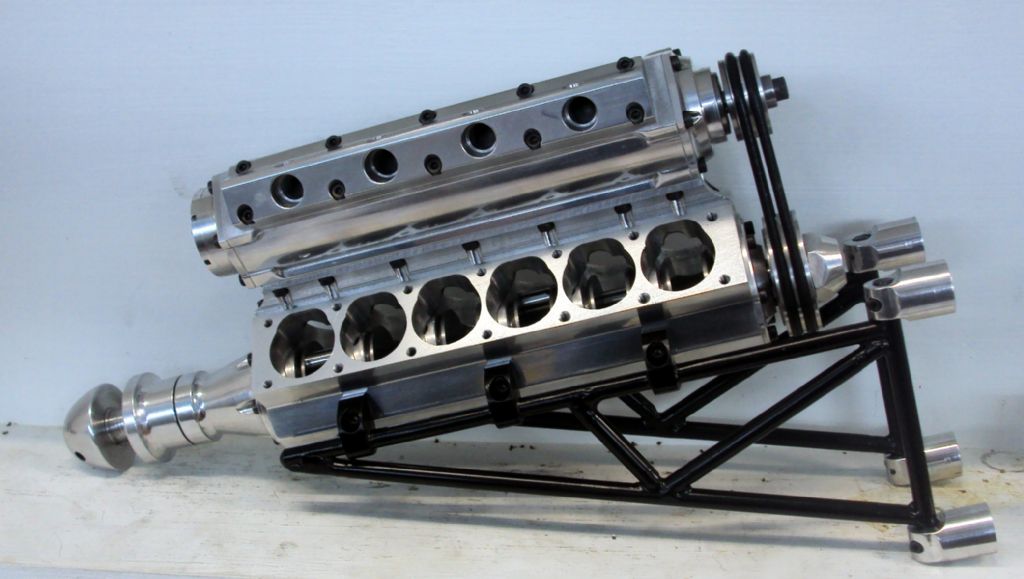

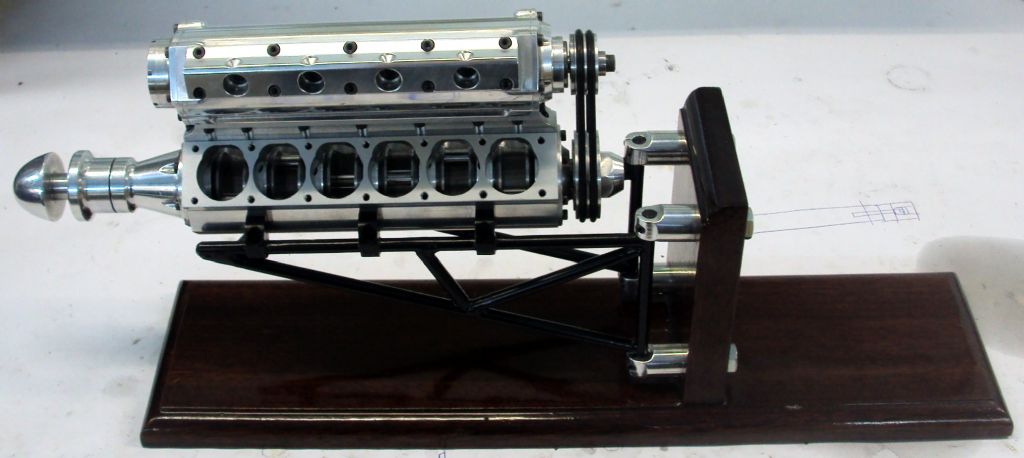

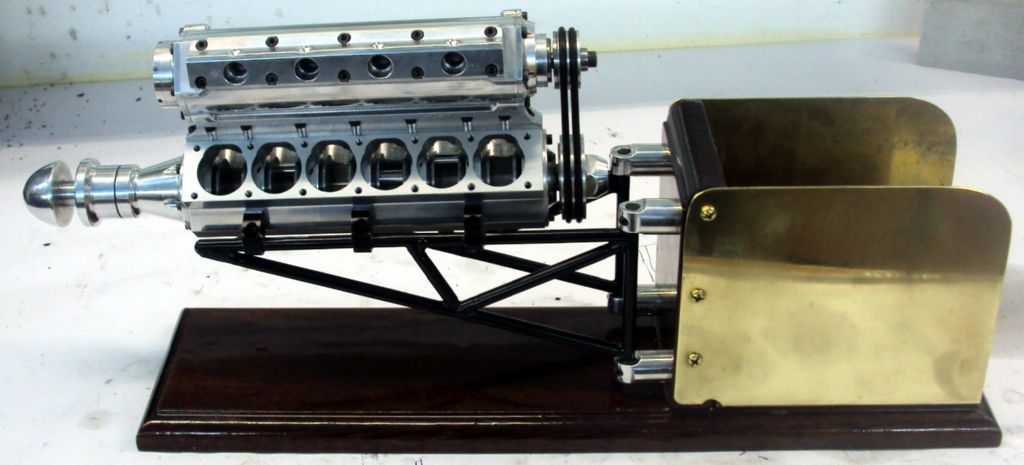

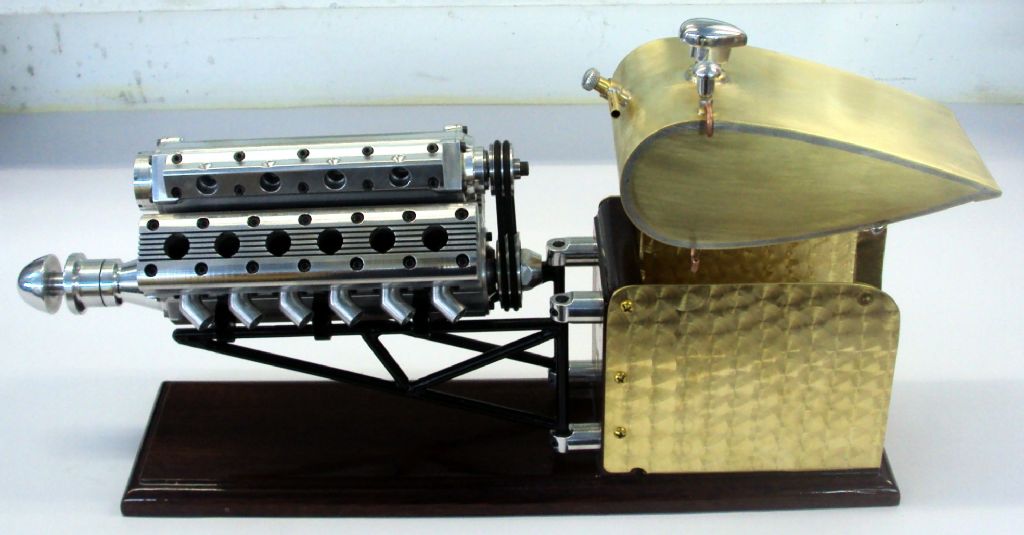

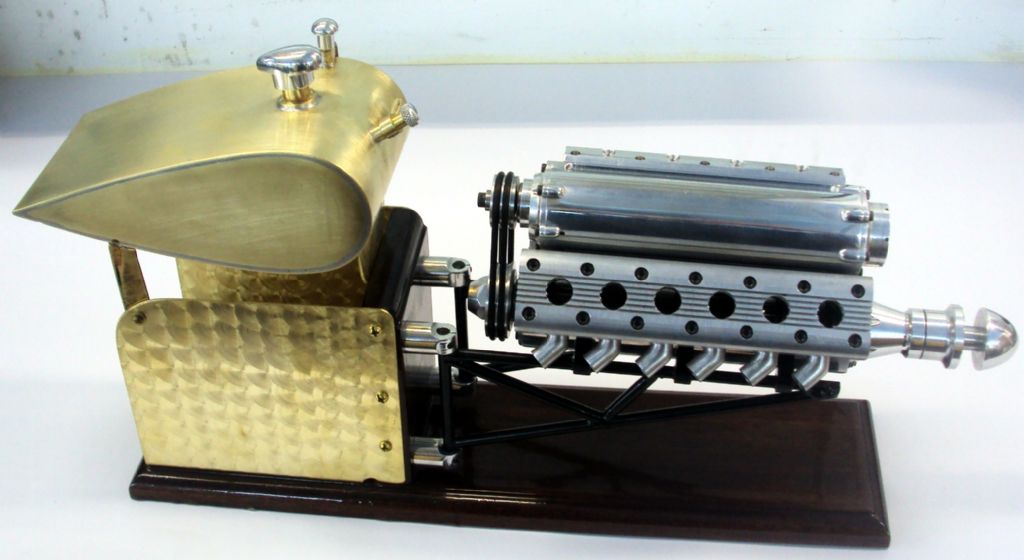

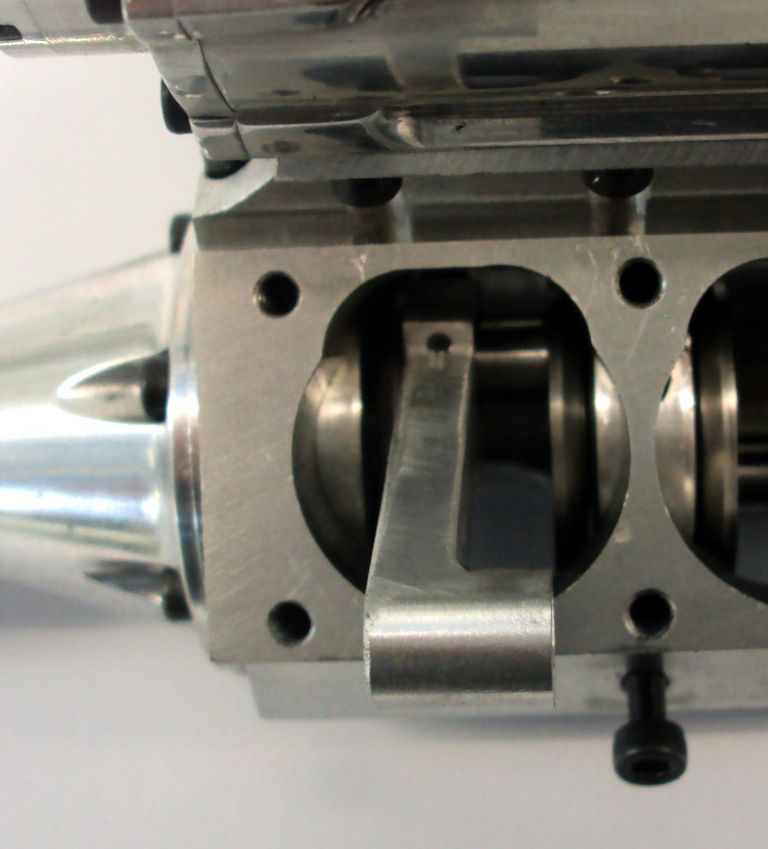

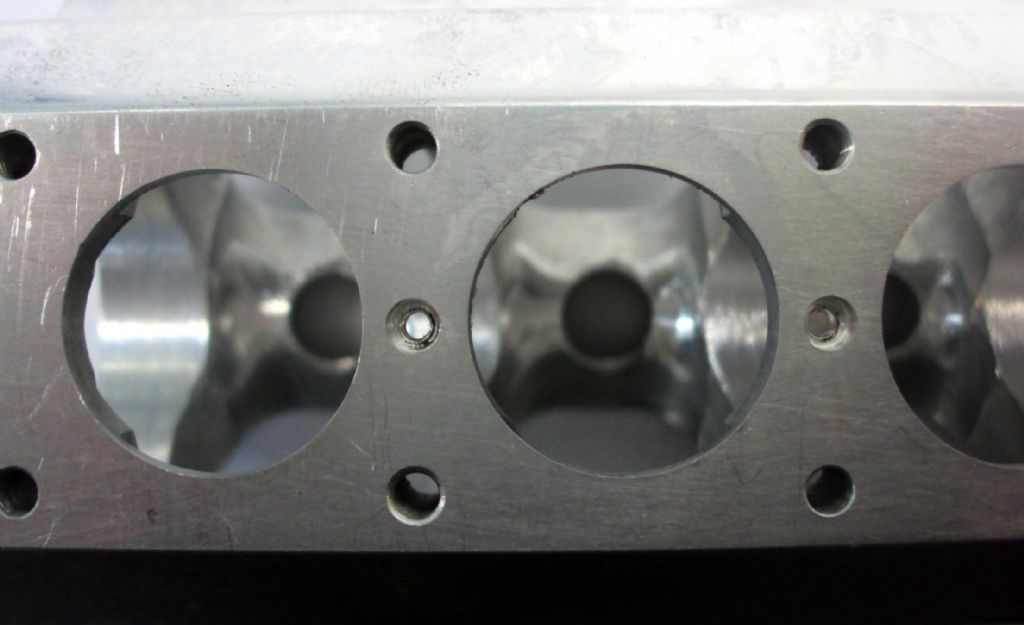

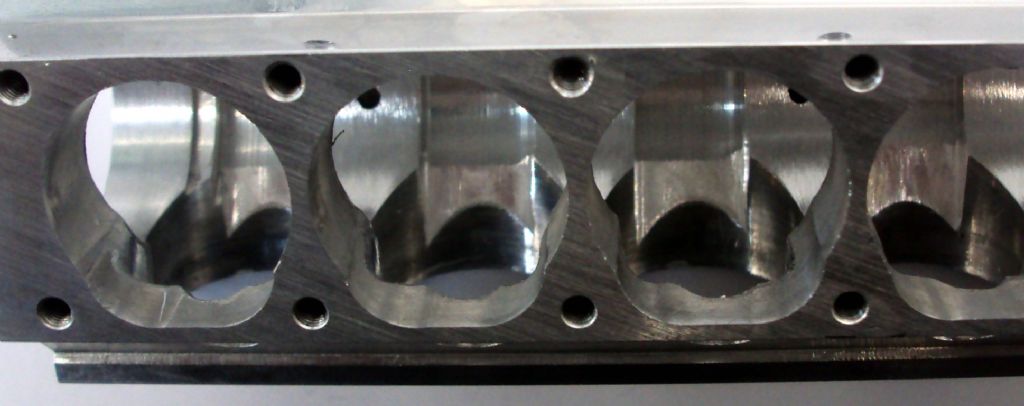

supercharged V12 2 stroke

supercharged V12 2 stroke

- This topic has 272 replies, 55 voices, and was last updated 13 December 2023 at 23:17 by

Steviegtr.

Steviegtr.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- How to wire up 3 phase motor and 3 phase converter?

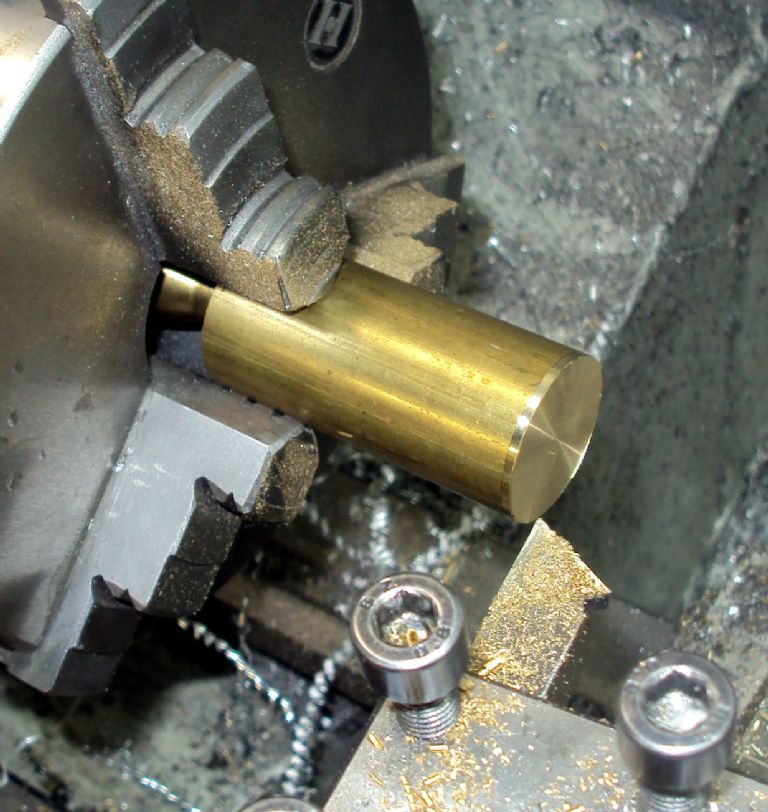

- Flattening brass plates

- My week this week! My workshop videos

- Problem getting the right parameters on a VFD

- Myford S7 Taistock Adjustment

- Morse Key

- James Coombes Drawing Error (or mine?)

- Measuring increments on boring head

- Flexispeed Meteor 2

- What Did You Do Today 2025